Air attemperation apparatus

A kind of air conditioning technology, applied in the field of air conditioning devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

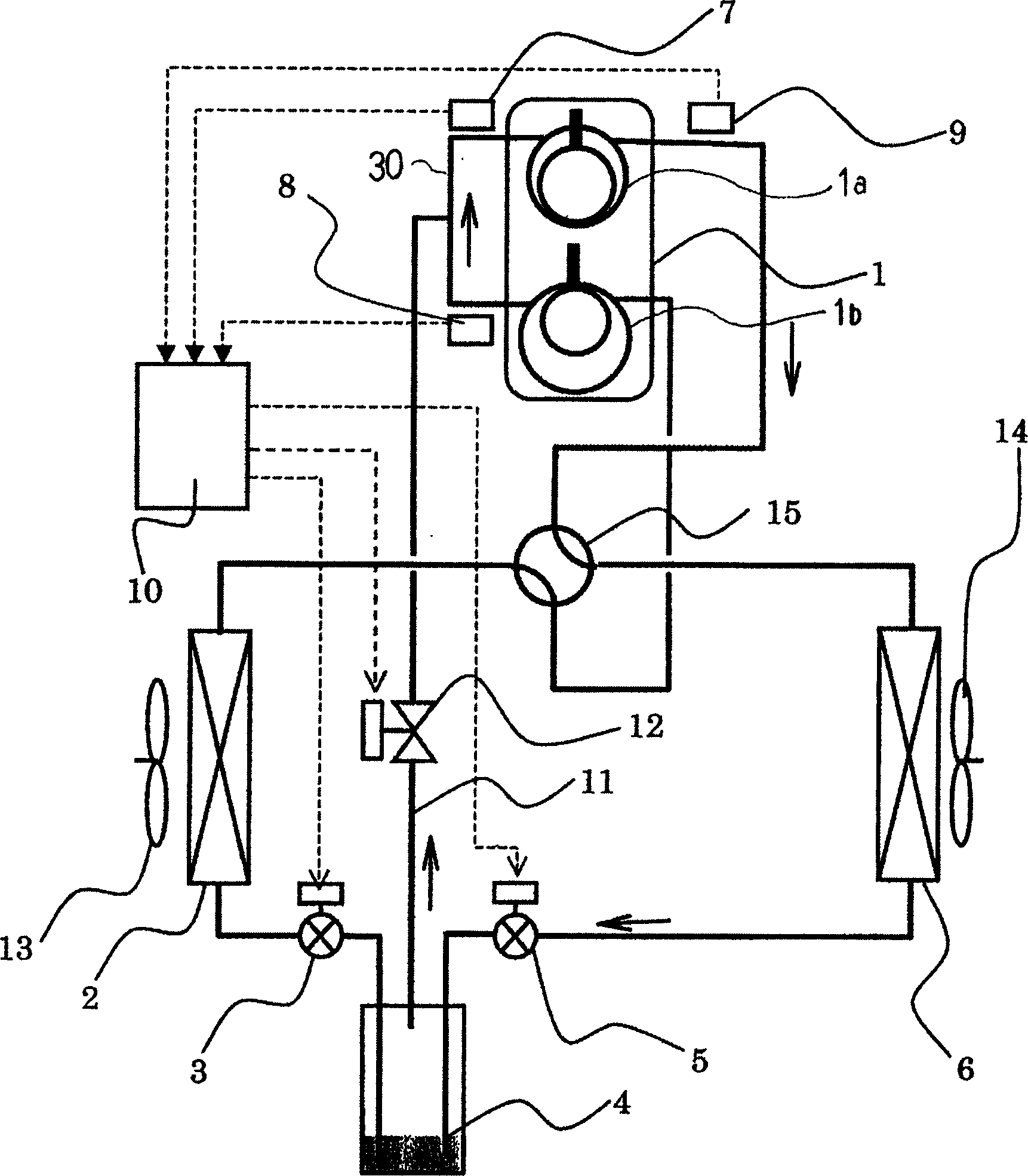

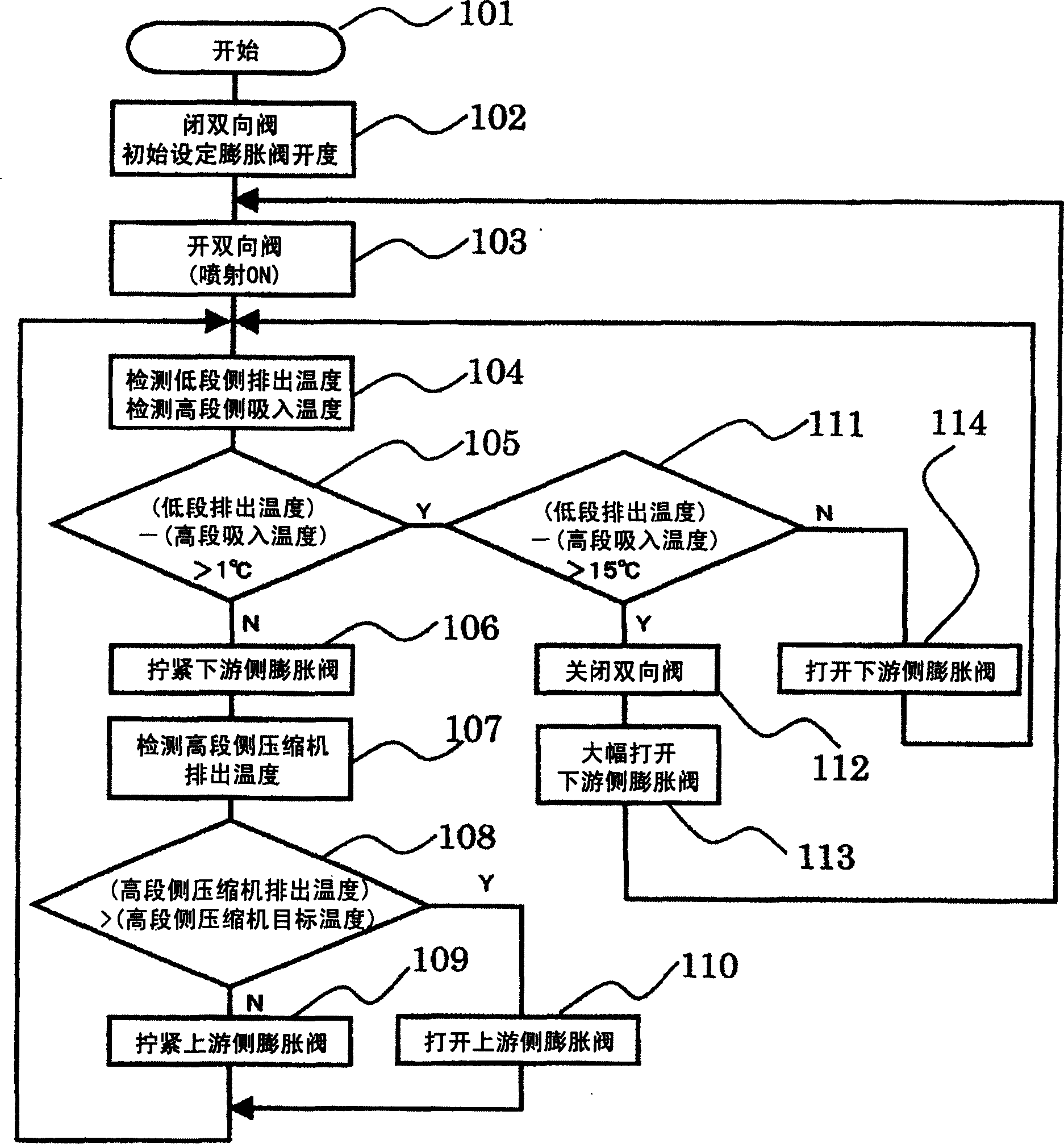

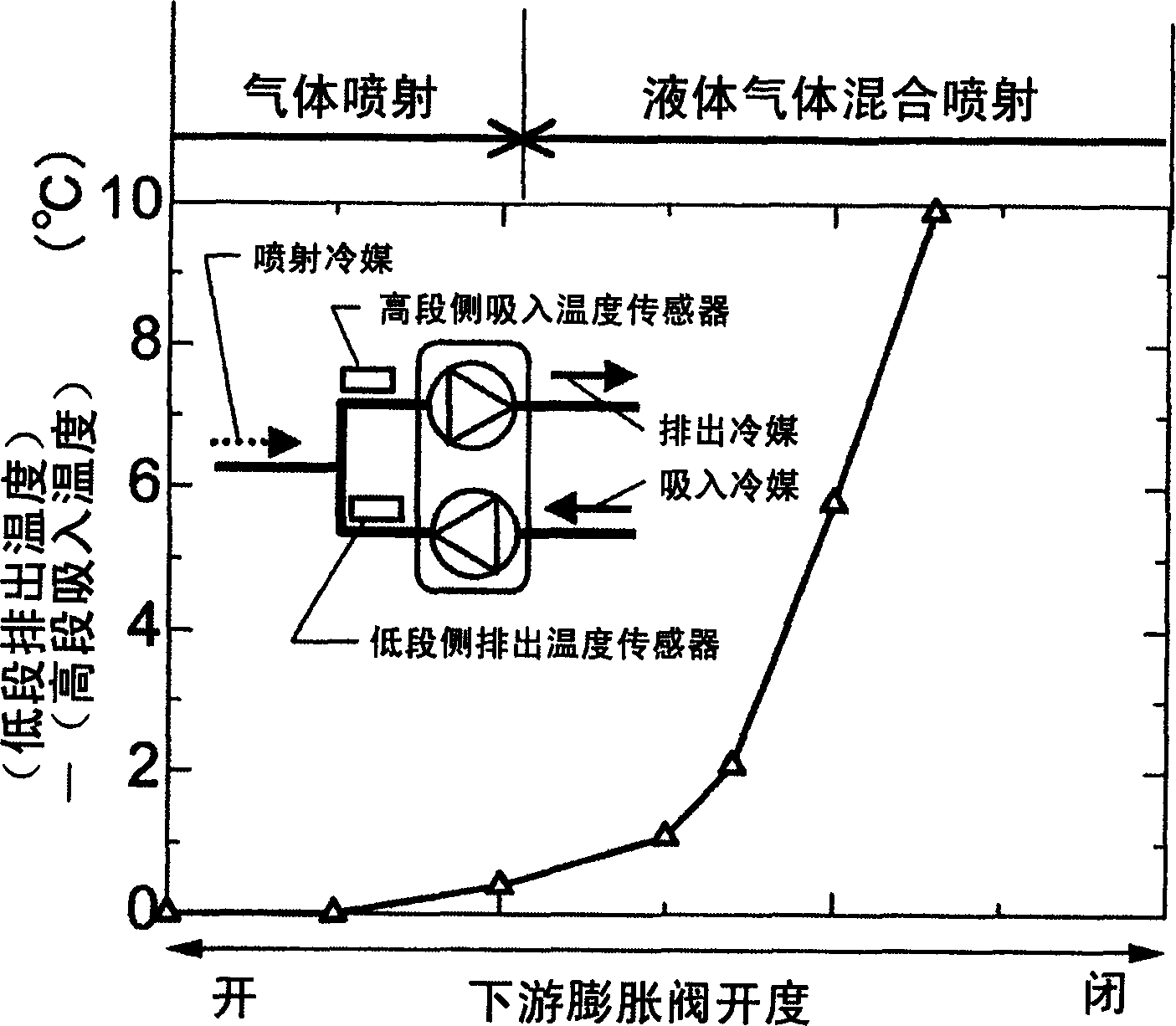

[0021] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. figure 1 It is a refrigerating cycle in an air-conditioning device with gas injection, and indicates the direction of refrigerant flow during heating operation. The two-stage compressor 1 is a compressor having two compression sections on a high-stage side (high-pressure side compressor section) 1a and a low-stage side (low-stage side compressor section) 1b, details of which will be described later. The outdoor heat exchanger 2 as the first heat exchanger functions as an evaporator during the heating operation (and as a condenser during the cooling operation). The second electric expansion valve 5 is a decompression unit with a variable decompression amount provided upstream in the refrigerant flow direction (downstream during air-cooling operation). The first electric expansion valve 3 is a decompression means with a variable decompression amount located dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com