Electric connector

A technology of electrical connectors and contacts, which is applied in the field of electrical connectors for differential transmission, can solve the problems of thin insulators, difficulty in integrating the positions of female contacts and thin insulators, poor processability, etc., and prevent deformation and bending , the effect of simple setting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

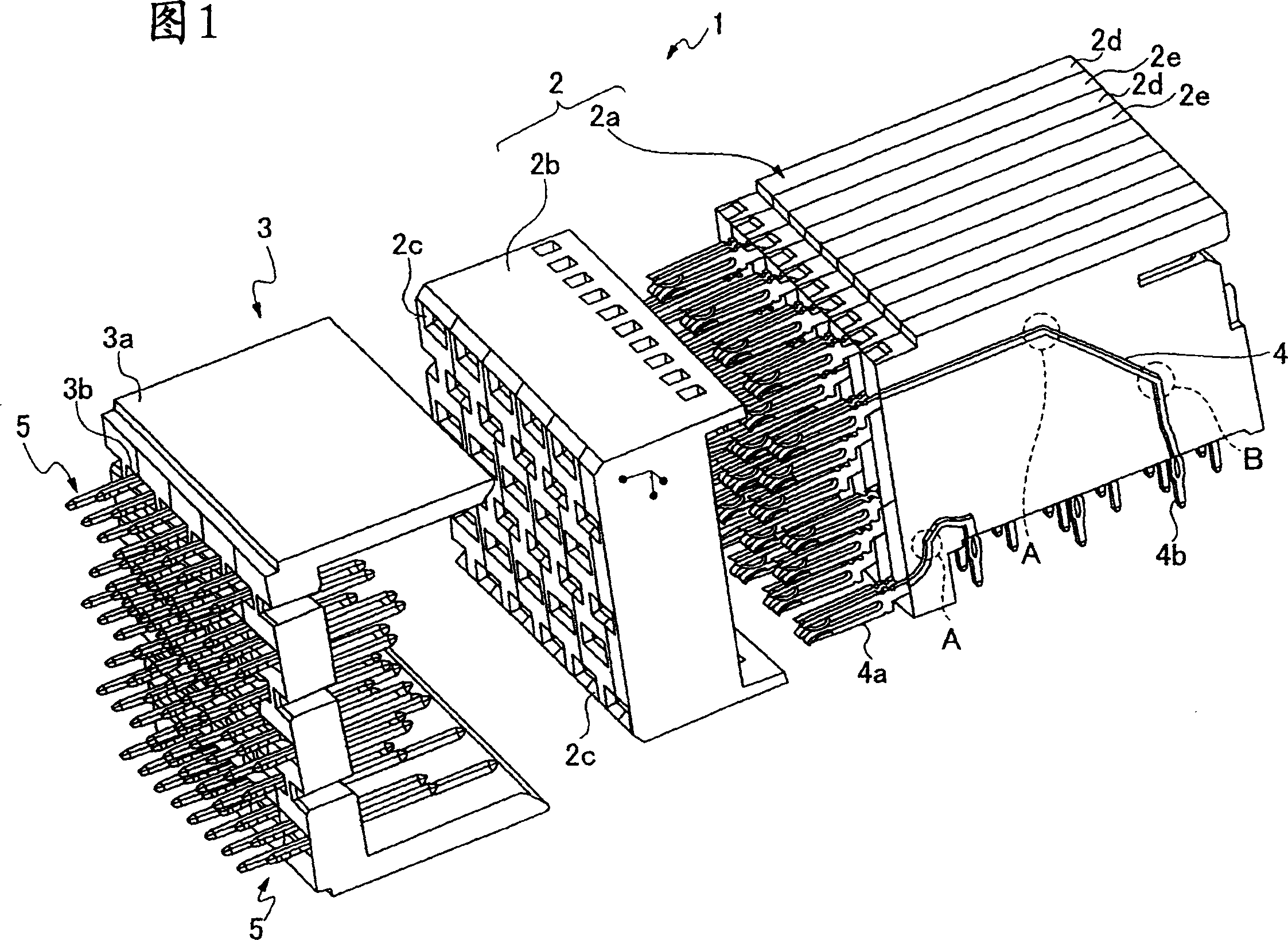

[0031] First, refer to Figure 1- Figure 8B The best mode for carrying out the present invention will be described. As shown in Fig. 1, the electrical connector 1 of the present invention is carried on the printed circuit board, one end of the contact is connected with the circuit, the other end of the contact forms the female mold connector 2 of the female mold connection part, and has The male contact point connected by the plug connector 2 is constituted by the backplane connector 3 arranged on the machine frame.

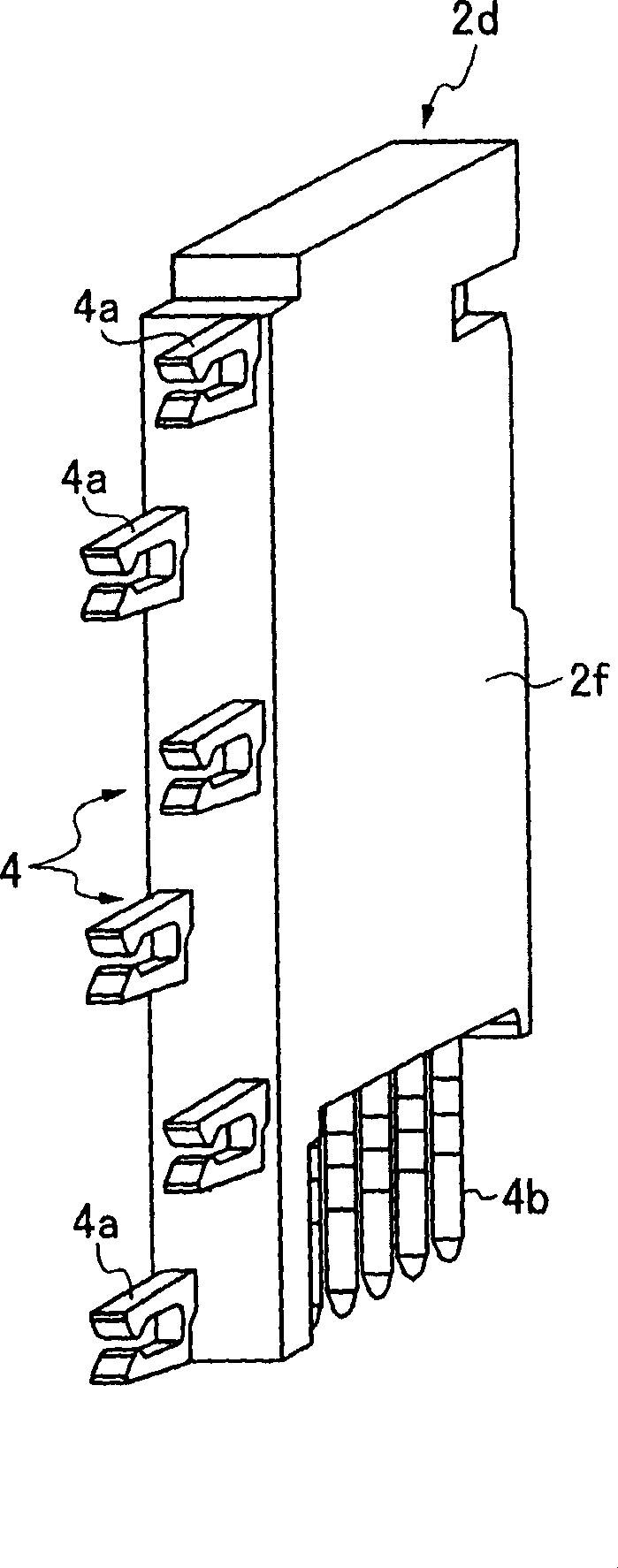

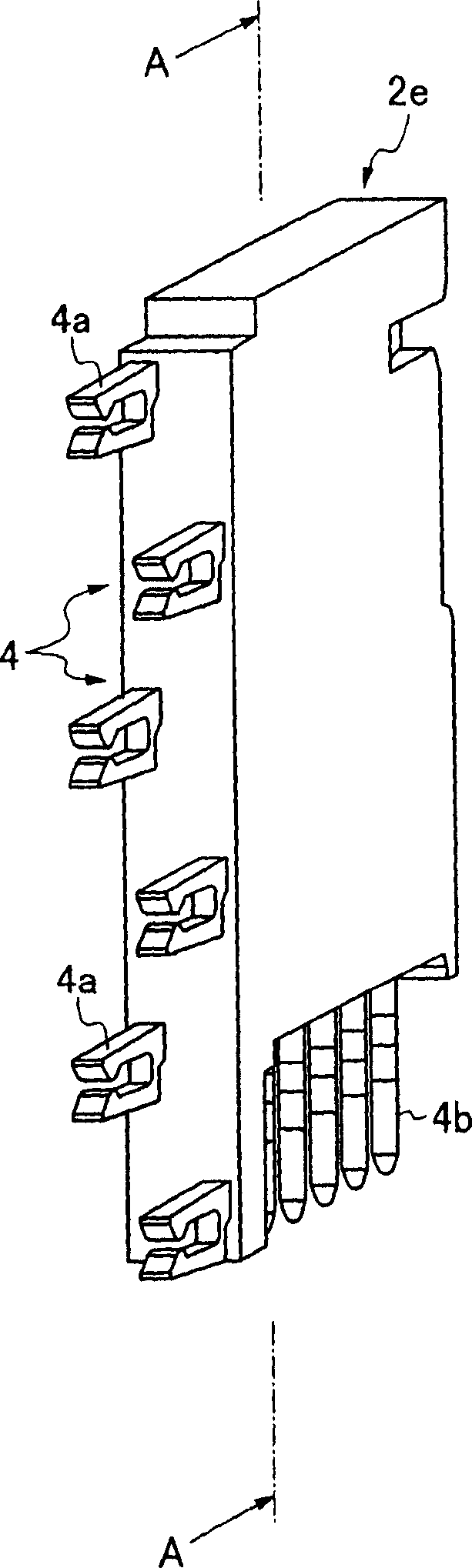

[0032] The plug connector 2 is composed of a joint housing 2b provided with a housing hole 2c for receiving the female connection part, a female contact housing 2a, and a female contact 4 formed into the female contact housing 2a by insert molding.

[0033] The coupling portion 4a of the female connection portion of the female contact 4 is accommodated in the receiving hole 2c as a mating terminal for transmitting an electrical signal. And the receiving holes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com