Method and device for mixing suspensions

A technology of mixing device and suspension, applied in textile and paper making, paper machine, fiber raw material processing, etc., to achieve the effect of saving cost, reducing equipment cost and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

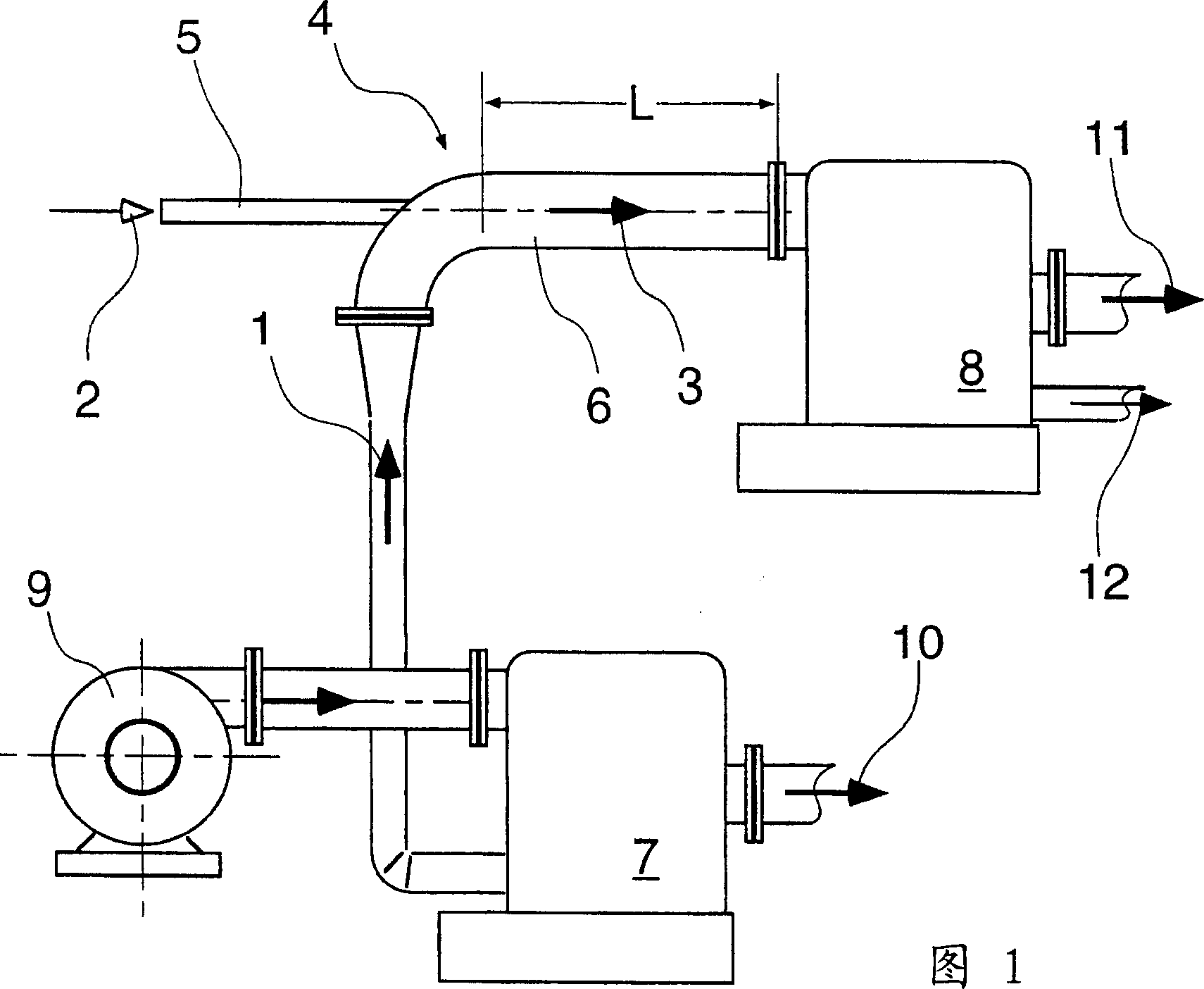

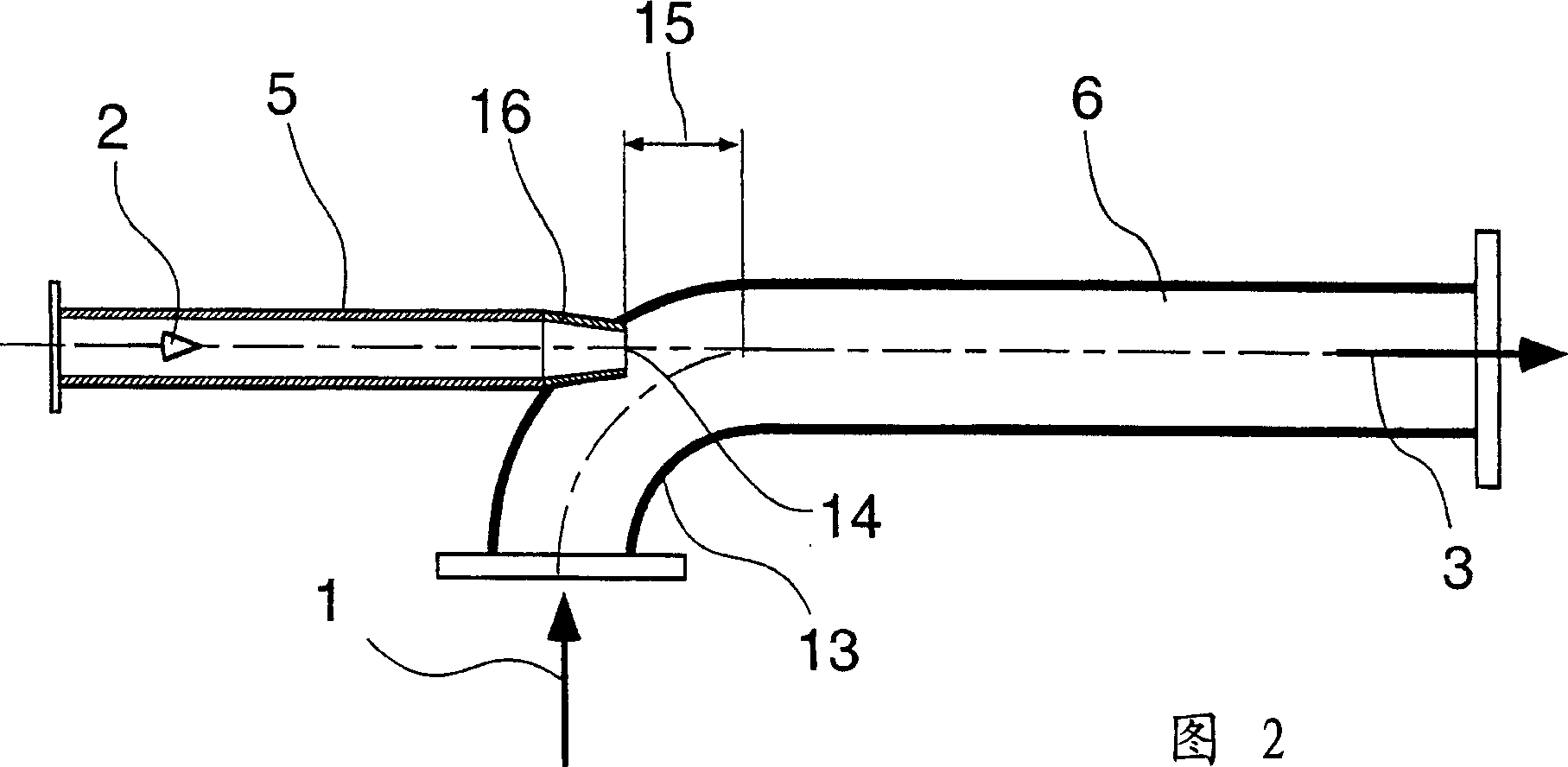

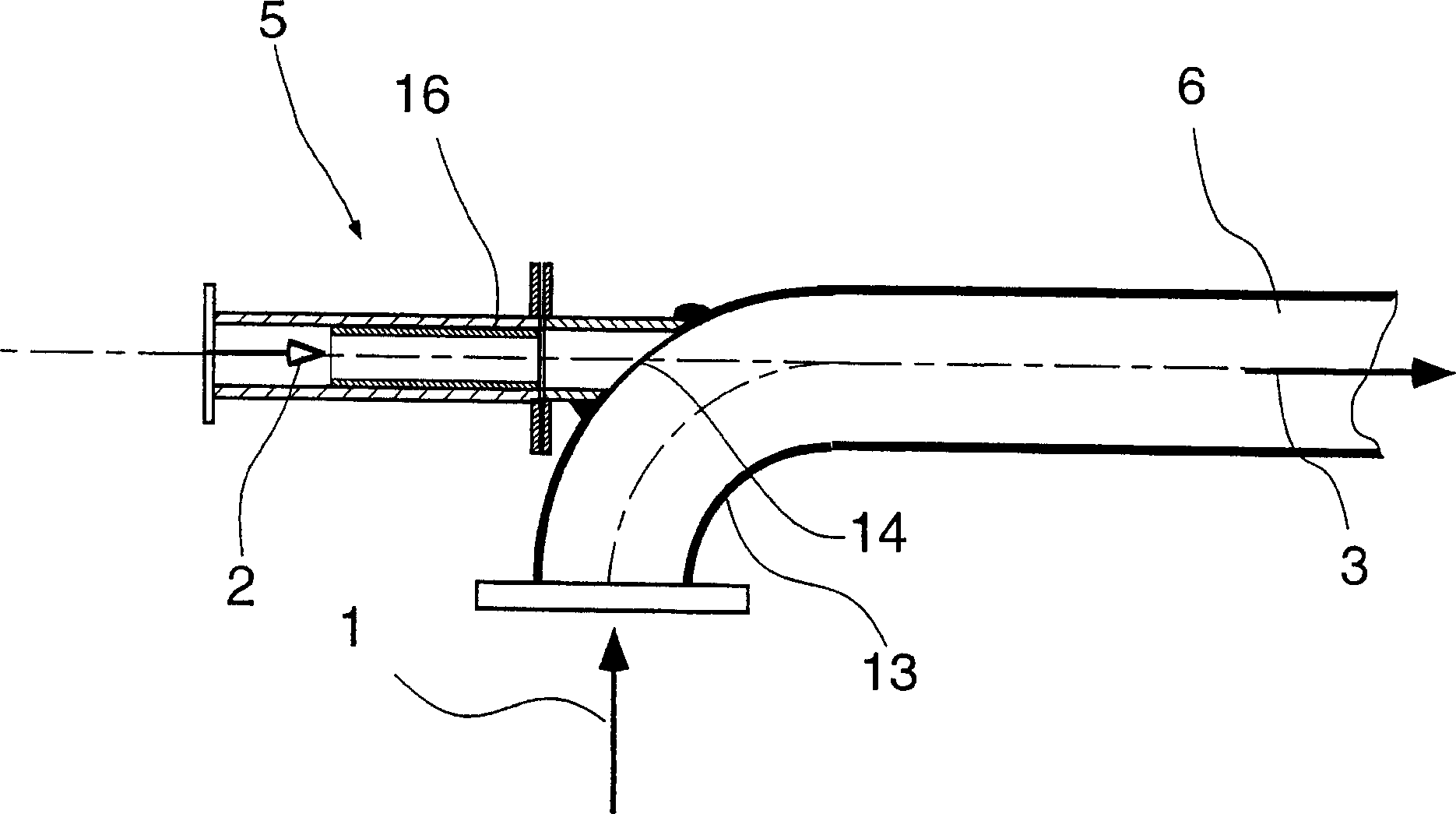

[0017] An important use of the method of the present invention is to dilute the pulp stream in a multi-stage screening apparatus in a paper mill. This situation is shown diagrammatically in FIG. 2 . The mixing device 4 in the form of a mixing tube here delivers as the main flow a fibrous material suspension 1 whose concentration or consistency is in the range from 2% to 6%. The fibrous material suspension 1 is formed here from the waste material of a pressure screening chamber 7 which is used in a manner known per se to remove unwanted foreign material from the fibrous material by means of a wet screening process separated from the suspension. The waste material, that is to say the fraction rich in impurities, constitutes the fibrous material suspension 1, which is to be diluted in the mixing device 4 and introduced into the mixing device 4 as the main flow. For this purpose, a diluent 2 (indicated by an open arrow) is sprayed into the mixing device 4 by means of a nozzle 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com