A new material sound absorption, insulation common sound shielding and producing method thereof

A new type of material, sound absorption and insulation technology, applied in the direction of noise absorption devices, sound insulation, manufacturing tools, etc., can solve the problems of sound absorption and sound insulation effects, etc., achieve good sound insulation effect, beautiful decoration, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

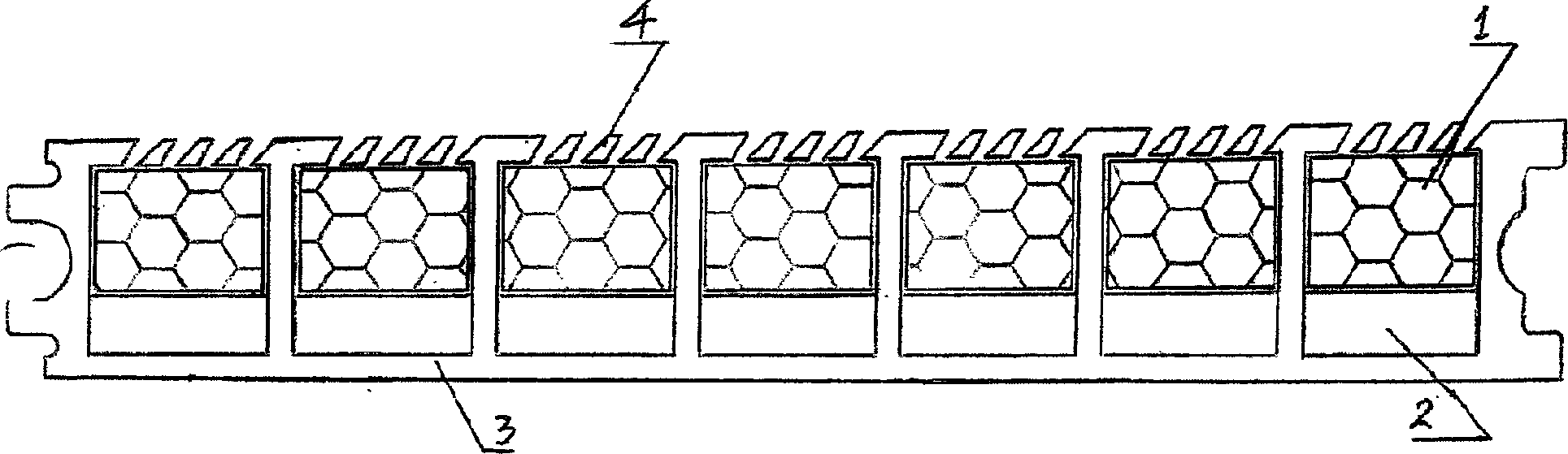

[0015] Such as figure 1 The GRC sound-absorbing and insulating body sound barrier of a new type of material, the inner cavity of the sound barrier is a sound-absorbing material cavity (1) at the front, and an air cushion cavity (2) at the rear. It is an alkali-resistant glass fiber reinforced cement component, which contains the following components (KG): 50 cement, 47 sand, 3 fibers, and an appropriate amount of water.

[0016] Preparation method: mix the above-mentioned components for later use, make a mold, and then carry out spray-casting molding.

Embodiment 2

[0018] Such as figure 1 The GRC sound-absorbing and insulating body sound barrier of a new type of material, the inner cavity of the sound barrier is a sound-absorbing material cavity (1) at the front, and an air cushion cavity (2) at the rear. It is an alkali-resistant glass fiber reinforced cement component, and the alkali-resistant glass fiber reinforced cement component contains the following components (KG): 40 cement, 40 sand, 2 alkali-resistant glass fibers, and an appropriate amount of water.

[0019] Preparation method: mix the above-mentioned components for later use, make a mold, and then carry out spray-casting molding.

Embodiment 3

[0021] Such as figure 1 The GRC sound-absorbing and insulating collective sound barrier of a new type of material, the inner cavity of the sound barrier is a sound-absorbing material cavity (1) at the front, and an air cushion cavity (2) at the rear. (3) Embossing is arranged at each part; shutters (4) are also arranged at the outer end of the sound barrier.

[0022] The raw screen body is an alkali-resistant glass fiber reinforced cement component, and the alkali-resistant glass fiber reinforced cement component contains the following components (KG): 60% cement, 55% sand, 4% alkali-resistant glass fiber, and an appropriate amount of water.

[0023] Preparation method: mix the above-mentioned components for later use, make a mold, and then carry out spray-casting molding.

[0024] This kind of sound barrier has the characteristics of sound absorption, good sound insulation effect, beautiful decoration and light weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com