Liquid-cooling radiating system micro-pump

A heat dissipation system and micro-pump technology, applied in the direction of non-variable pumps, pumps, pump devices, etc., can solve the problems of impeding the rotation of the impeller, hindering the circulation of the working liquid, reducing the heat dissipation effect, etc., to reduce disturbance and improve the heat dissipation effect , the effect of improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

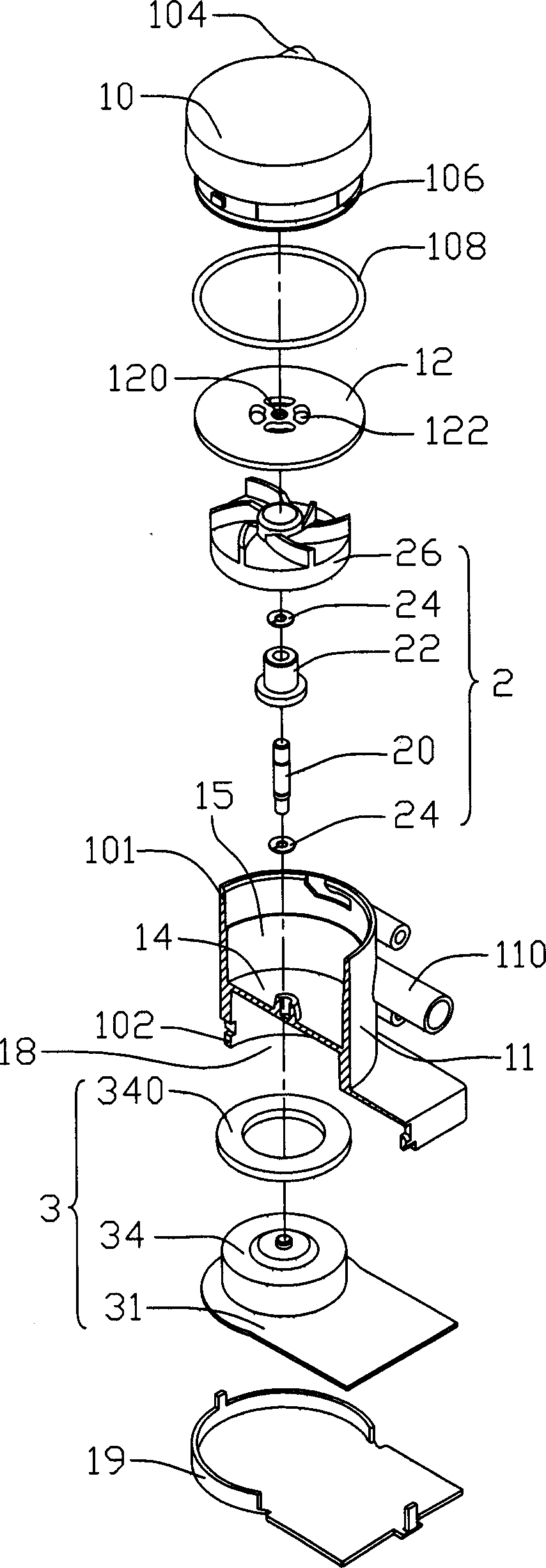

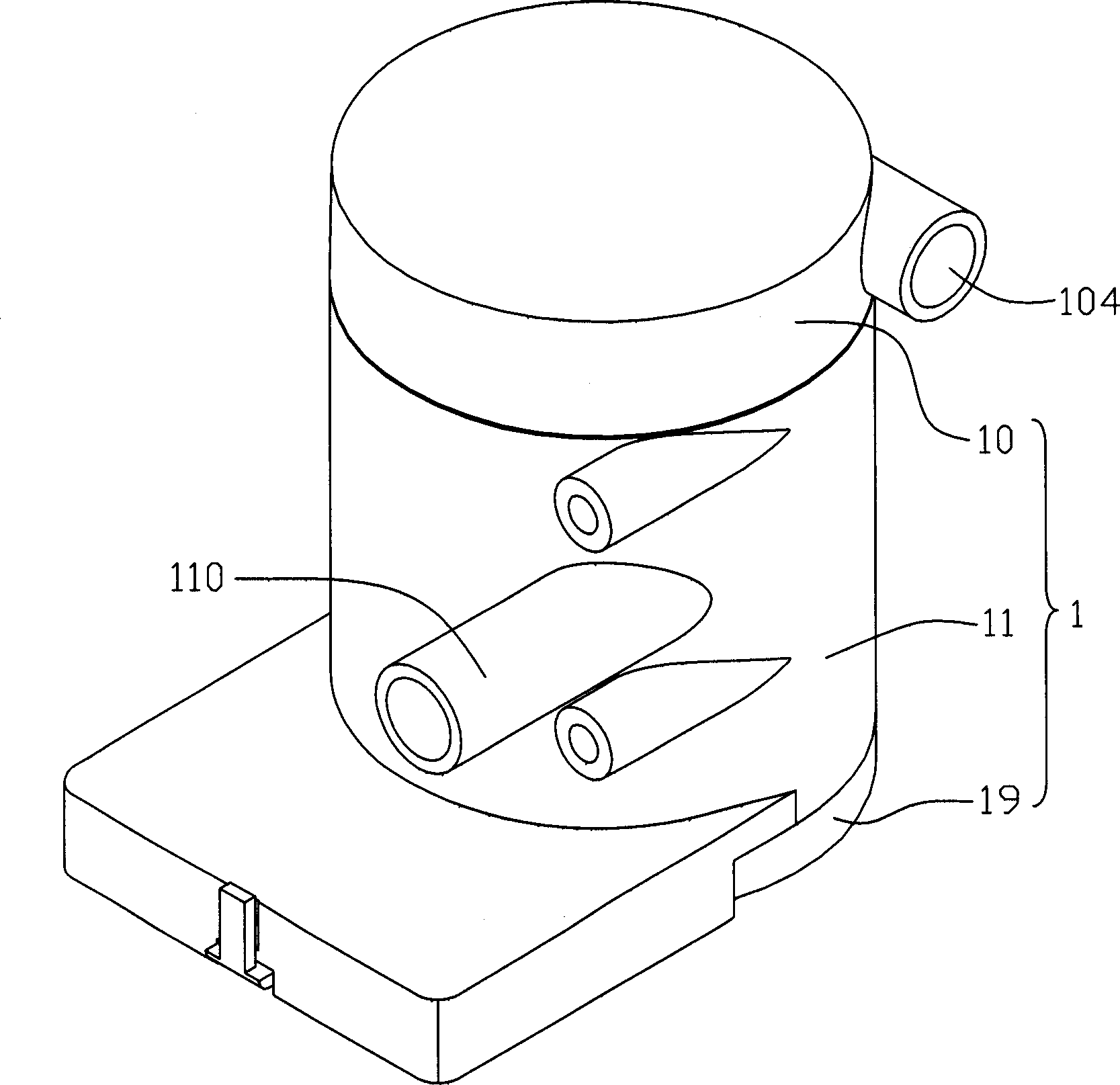

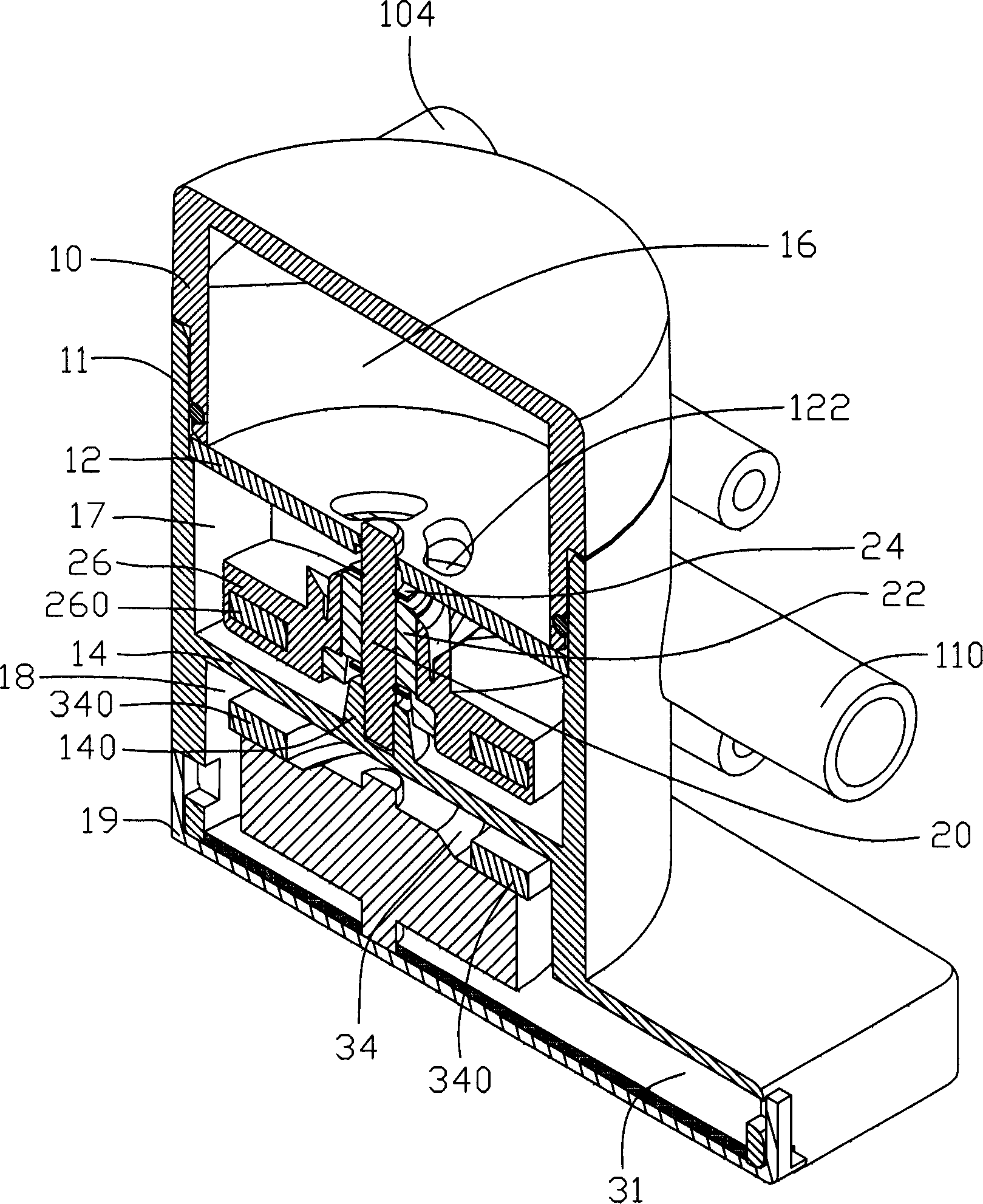

[0012] Please refer to figure 1 and figure 2 As shown, the micropump of the liquid cooling heat dissipation system of the present invention includes a casing 1 , an impeller set 2 assembled in the casing 1 and a driving unit 3 , wherein the impeller set 2 is driven to rotate by the driving unit 3 .

[0013] The casing 1 includes a hollow body 11 and an upper cover 10 and a lower cover 19 fastened with the body 11 . The upper and lower covers 10 , 19 are respectively fitted with the top end 101 and the bottom end 102 of the main body 11 to form an integral body. A sealing ring 108 is disposed between the upper cover 10 and the top end 101 of the body 11 to prevent leakage of working fluid. The lower end of the upper cover 10 is provided with an annular groove 106 matched with the sealing ring 108 . The upper cover 10 is also provided with a liquid inlet port 104 .

[0014] A baffle 14 is disposed inside the body 11 , thereby forming an upper chamber 15 and a lower chamber ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap