Quick joint coupling for lines comprising locking means rotatably arranged in relation to the female part

一种锁定装置、联接器的技术,应用在管子/管接头/管件、联轴器、可调连接等方向,能够解决困难、变形等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

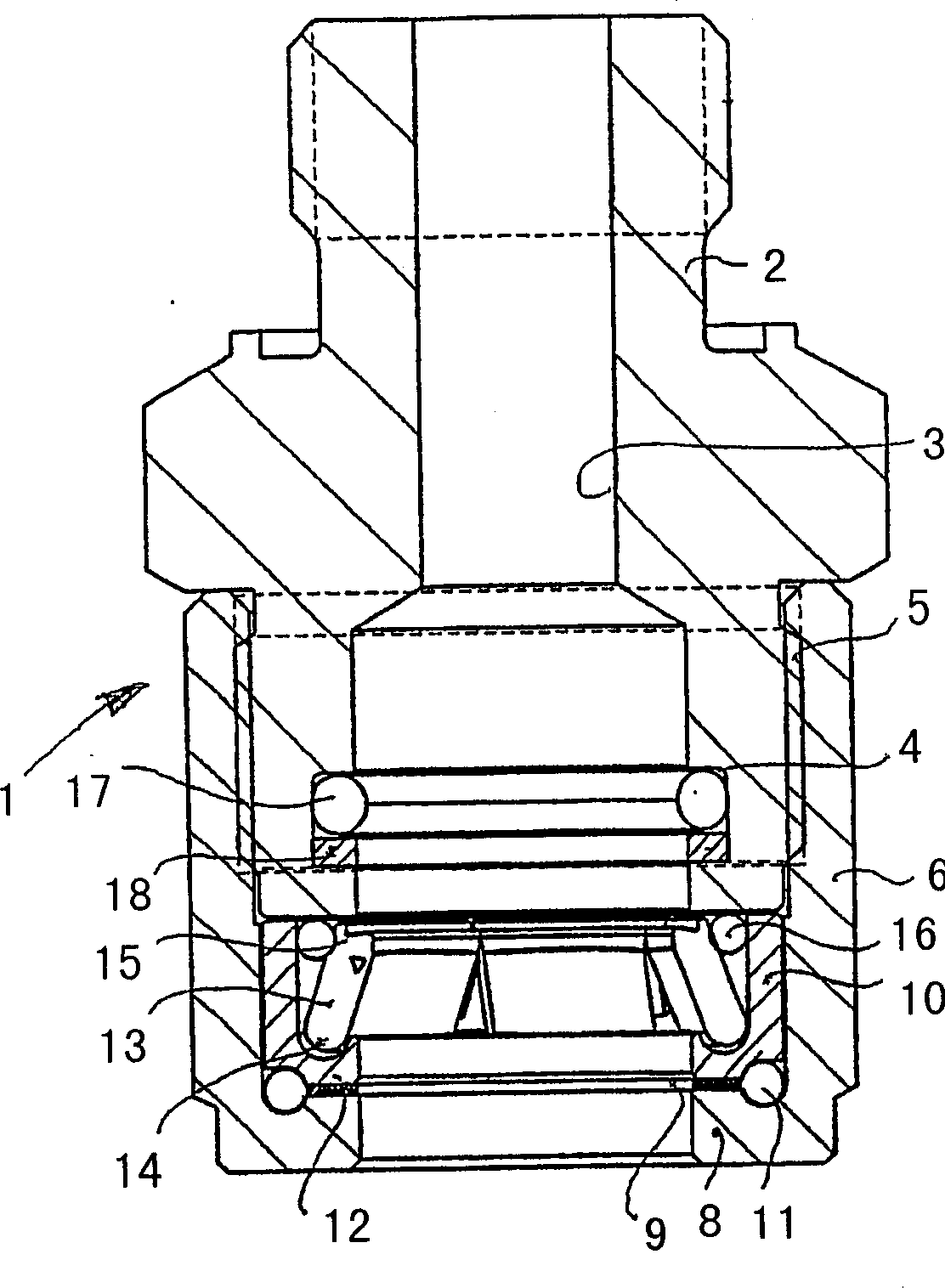

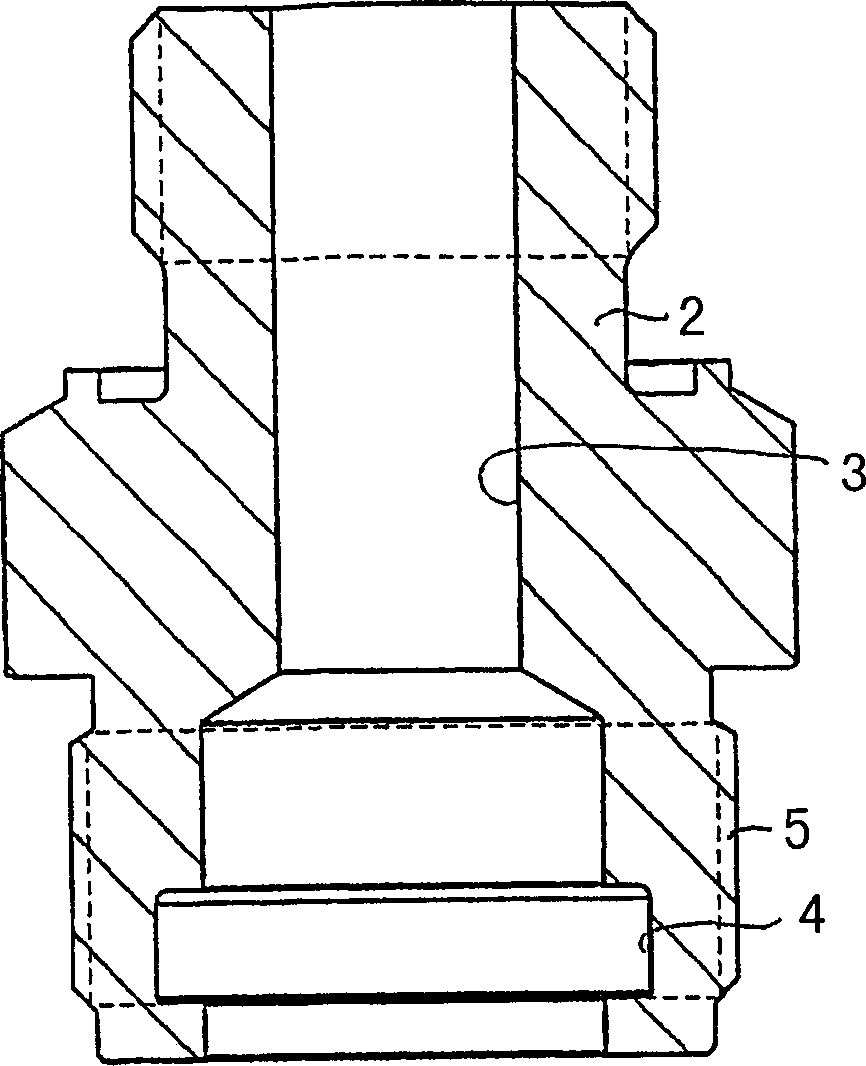

[0031] 1 denotes a female part comprising a rear, hose (not shown) receiving part 2 comprising a tubular lead-in part 3 to allow the passage of media such as hydraulic oil. At one end thereof, referred to here as the front end, the lead-in part 3 has a groove 4 thereon, which has a larger diameter than the lead-in part itself. The hose receiving part 2 has on its outside a threaded part 5 which is arranged to connect the hose receiving part 2 to a rotary part 6 .

[0032] The rotating part 6 consists of a substantially cylindrical tubular part having at its rear end an internal thread 7 arranged to cooperate with the thread 5 to connect the two elements 2 and 6 . The rotating part 6 has at its one end, here referred to as the front end, an annular flange 8 intended to be partly for a sliding seal 9 and partly for a substantially cylindrical tubular bearing supported thereon A support plane for the cup 10.

[0033] Between the rotating part 6 and the cylindrical tubular beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com