Pipe fixing system

A pipeline fixing and pipeline technology, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, passing through components, etc., can solve the problems of a lot of time and manpower installation, complicated disassembly by workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Referring now to the drawings, the present invention will be described in detail using preferred apparatus.

[0025] According to the present invention, the pipe fixing system is the basic part of the pipe structure for inserting and fixing the pipe.

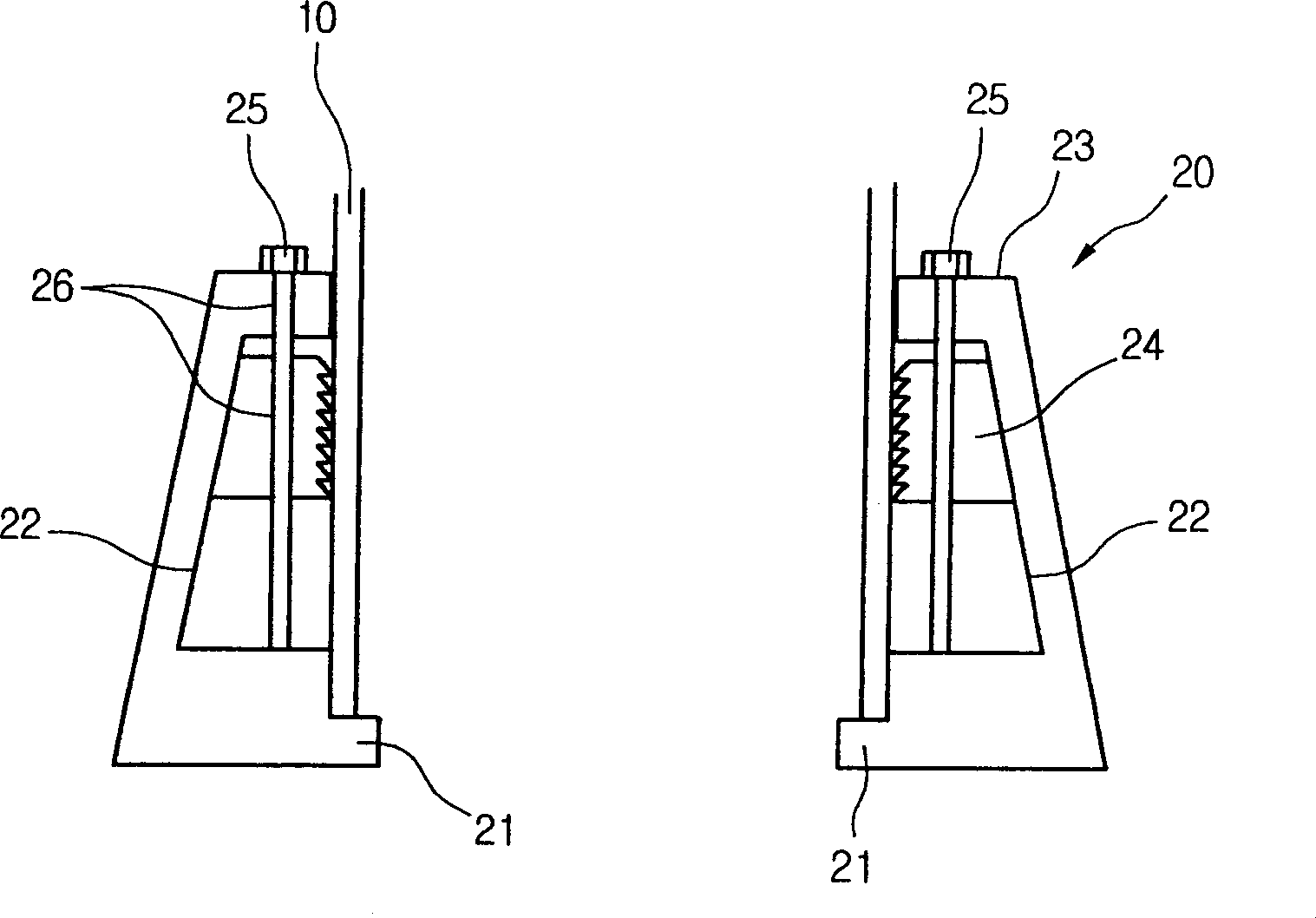

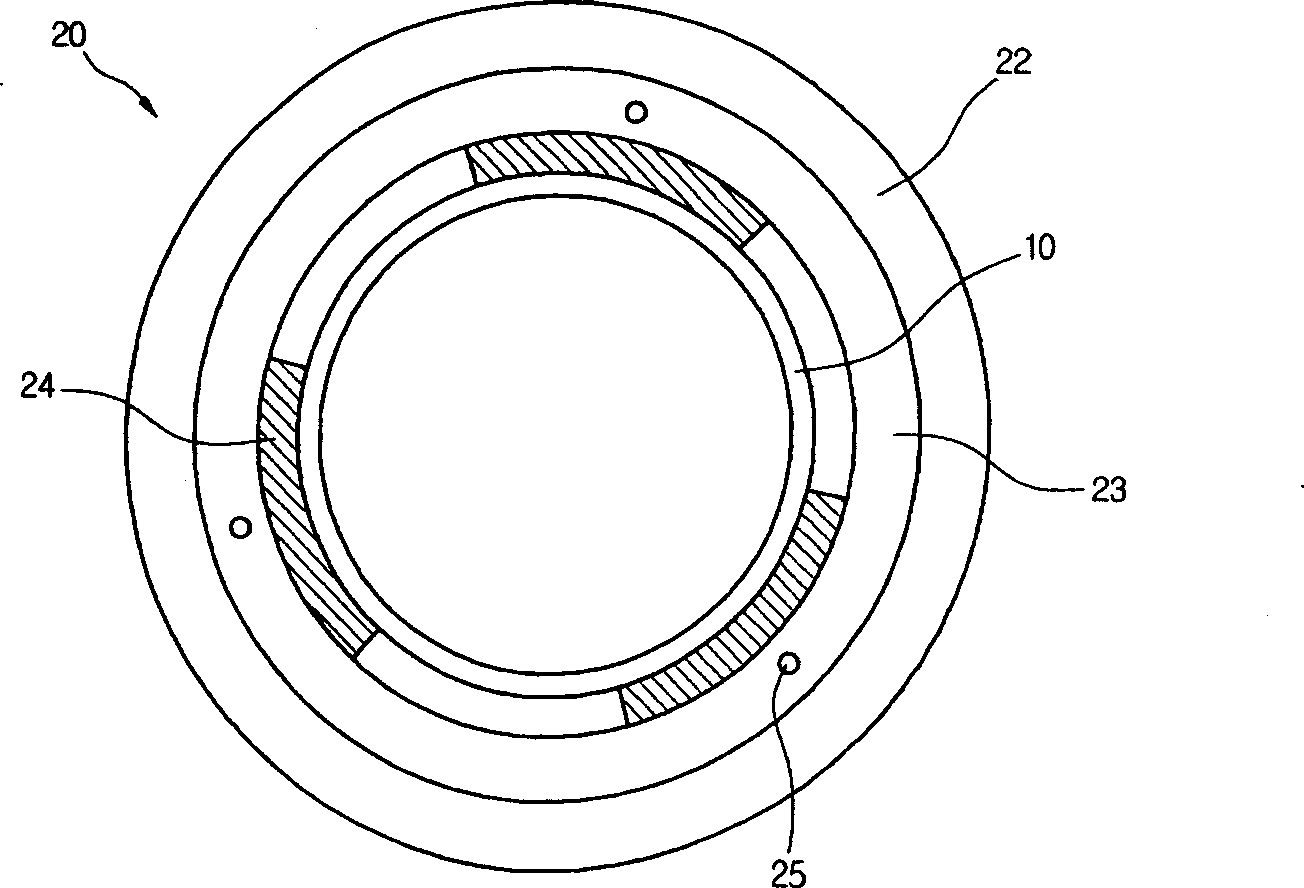

[0026] The main body 20 includes a blocking portion 21 formed at its inner bottom to prevent the pipe 10 from being inserted into the main body 20, an extension portion extending from the blocking portion 21 to a predetermined portion of the main body 20 to closely contact and fix the pipe 10, a tapered portion 22 , which has an inner hollow portion and has a gradually narrowing slope relative to the inlet 23 formed by bending the tapered portion 22 into a "" shape for insertion into the pipe 10 .

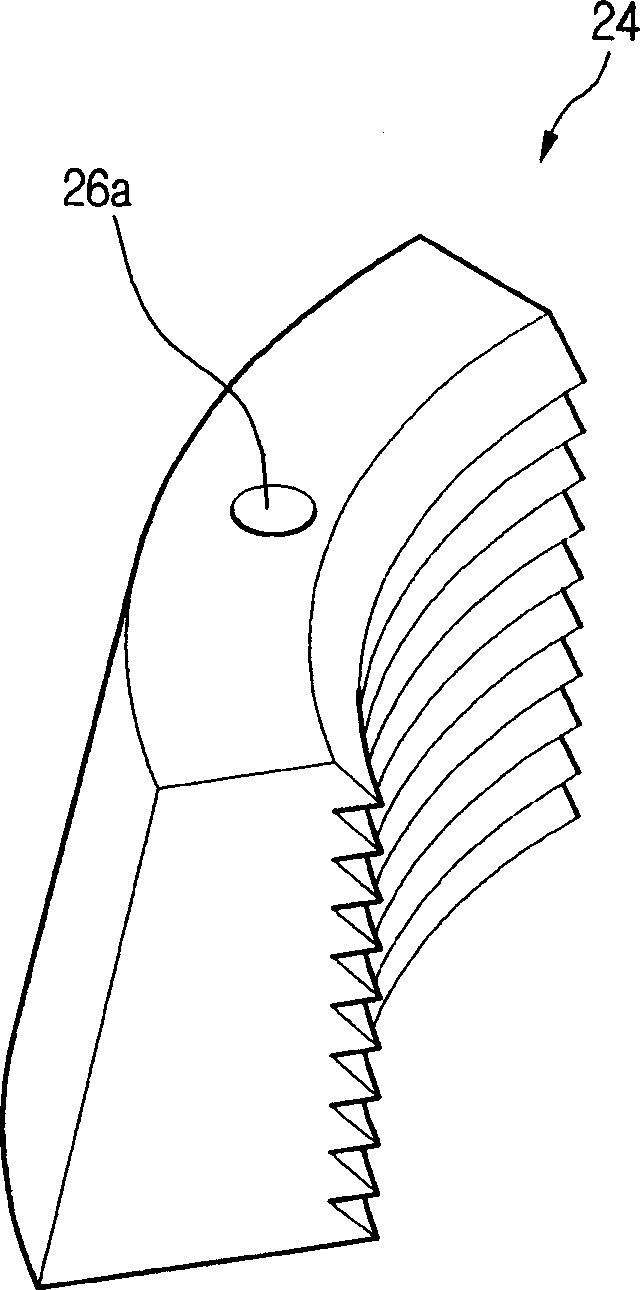

[0027] The fixed substrates 24 are placed in the hollow portion of the tapered portion 22, and each of the substrates 24 is narrower at the upper part and wider at the lower part. The upper part of the substrate 24 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com