Push-stop bar unit

A technology of stop rods and struts, which is applied in the field of shock stop rods, and can solve problems such as permanent deformation of shock stop rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

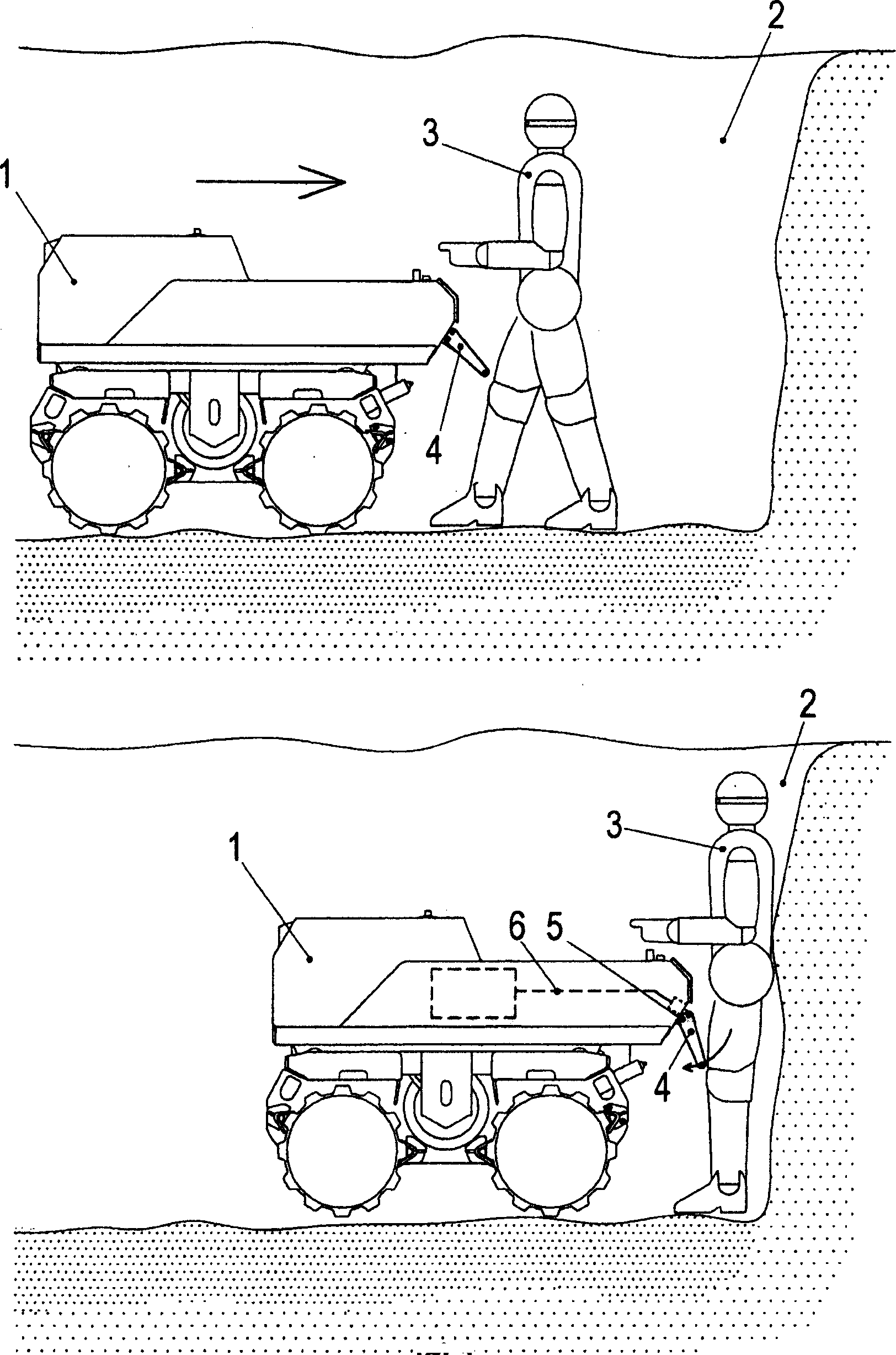

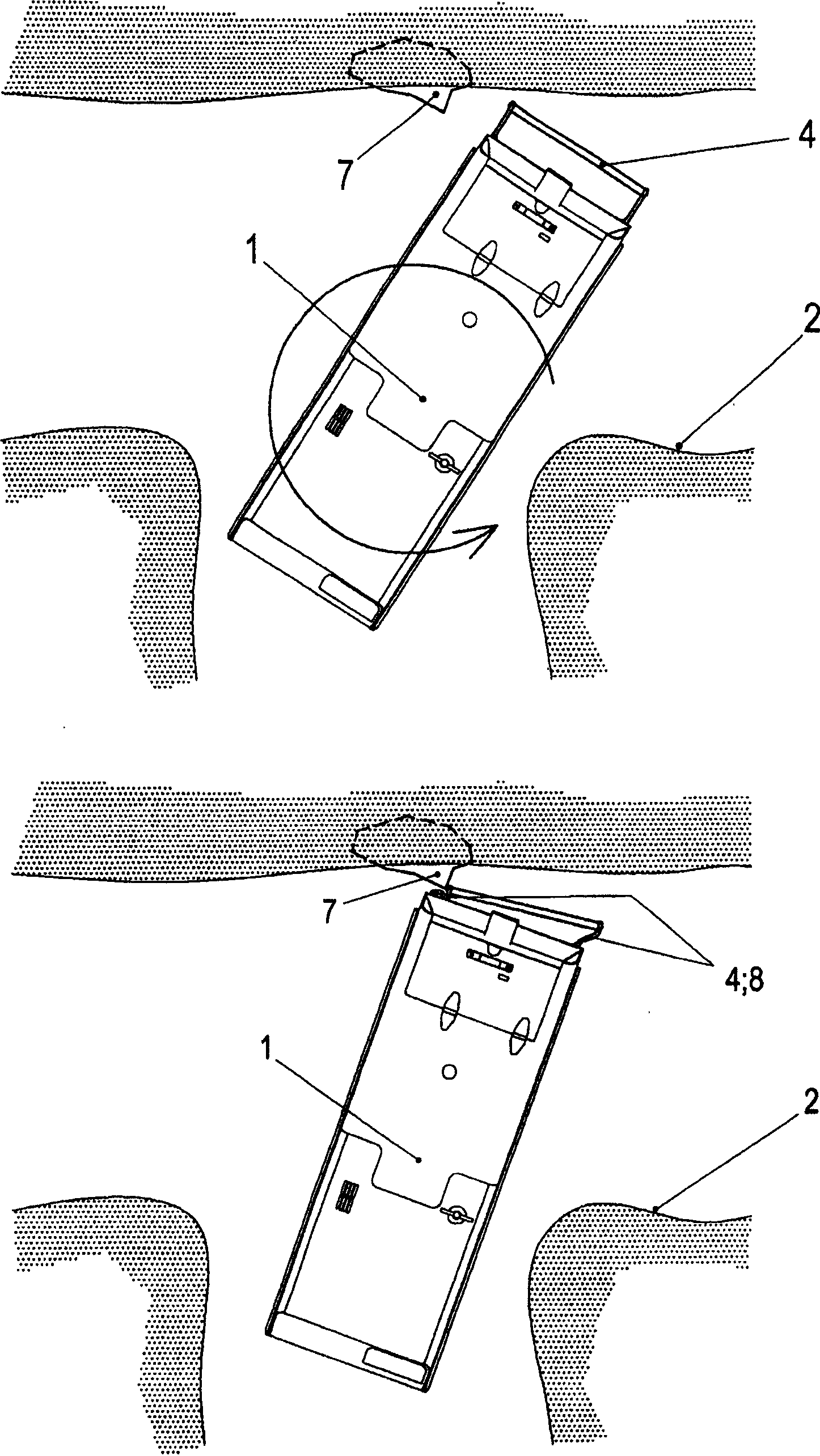

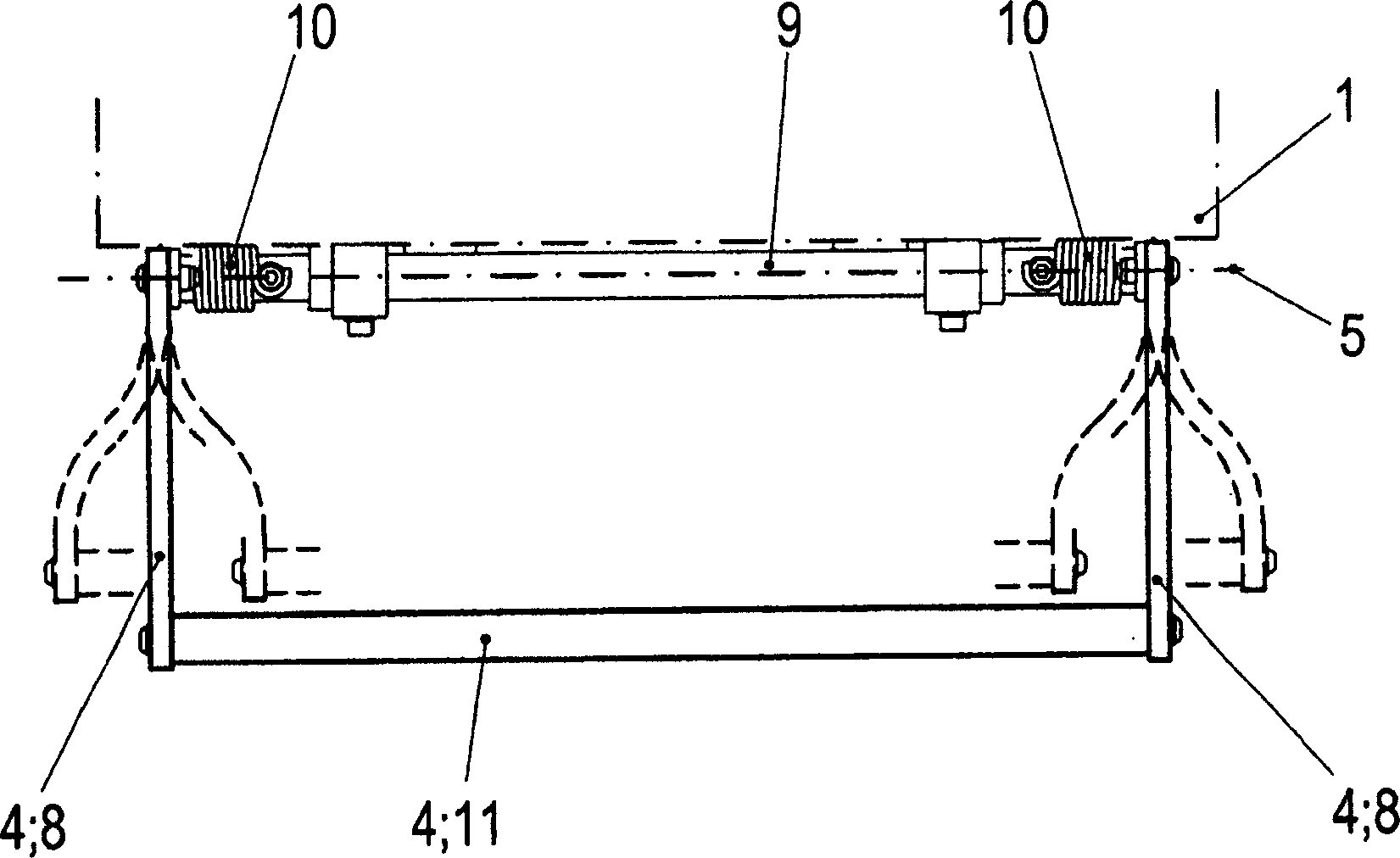

[0007] figure 1 A self-propelled walk-controlled roller compactor is shown in the form of a trench compactor 1 in operation. The trench compactor 1 has vibrating drums fitted with pads and is used to compact the bottom of the trench 2 . The trench compactor 1 is usually remotely controlled by an operator standing on the edge of the trench 2 . In the figure, because the operator 3 manually operates the trench compactor 1, he comes down into the trench 2.

[0008] In the upper part of the figure, the operator 3 has activated the trench compactor 1 to reverse in the direction of the arrow and is walking backwards behind the compactor. The trench compactor 1 is equipped with an impact stop bar 4 according to the invention. At this moment, the impact stop lever 4 is in an effective non-triggered state.

[0009] In the lower part of the figure, the backward movement of the operator 3 has been stopped by an obstacle, and he does not try to bring the trench compactor 1 in reverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com