Axial air-gap electronic motor

一种轴向气隙、电动机的技术,应用在制造电动发电机、电动组件、带有静止电枢和旋转磁体的同步电动机等方向,能够解决不能位置检测、高精度的感测难以进行、制造成本提高等问题,达到可靠感测、高精度感测的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

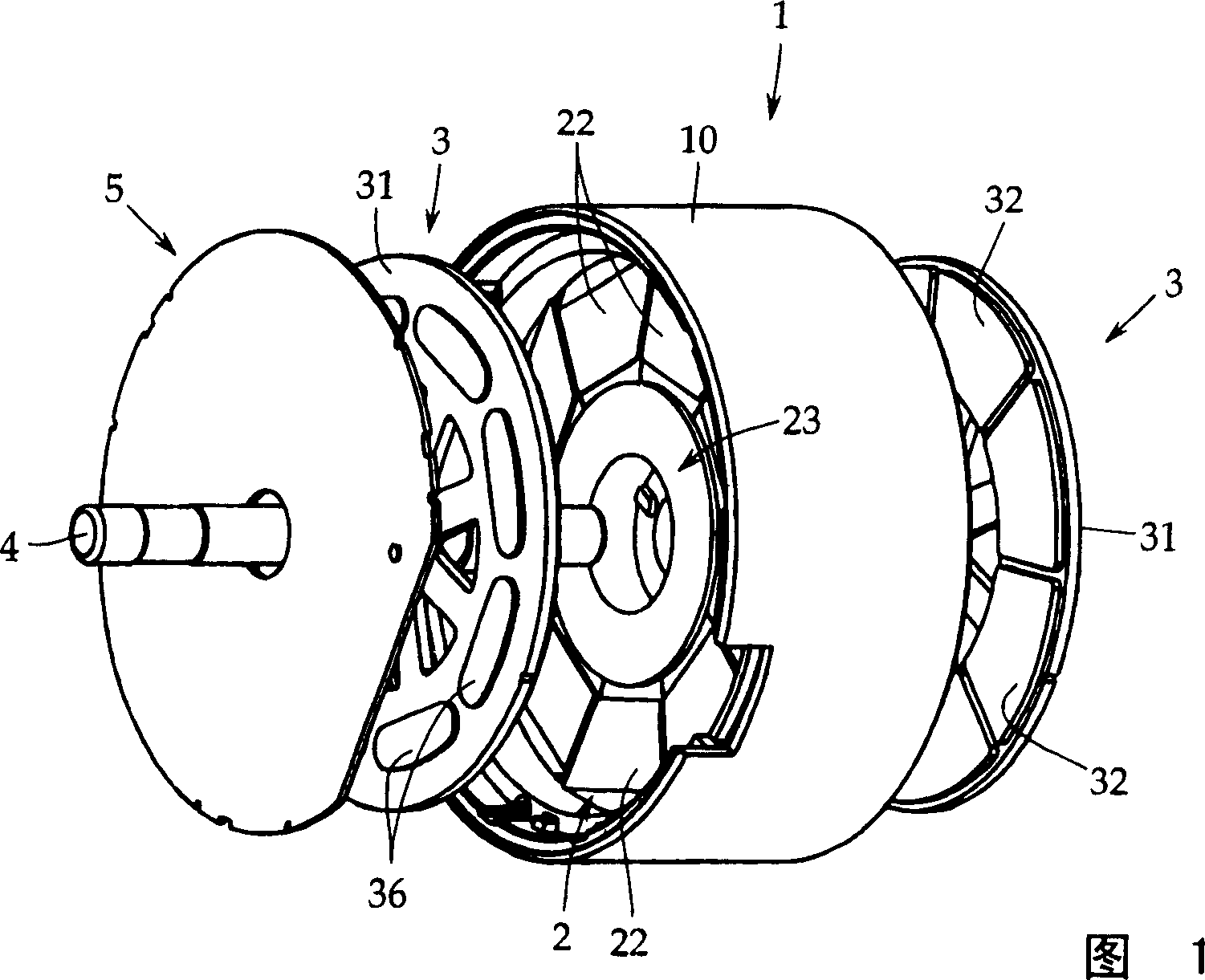

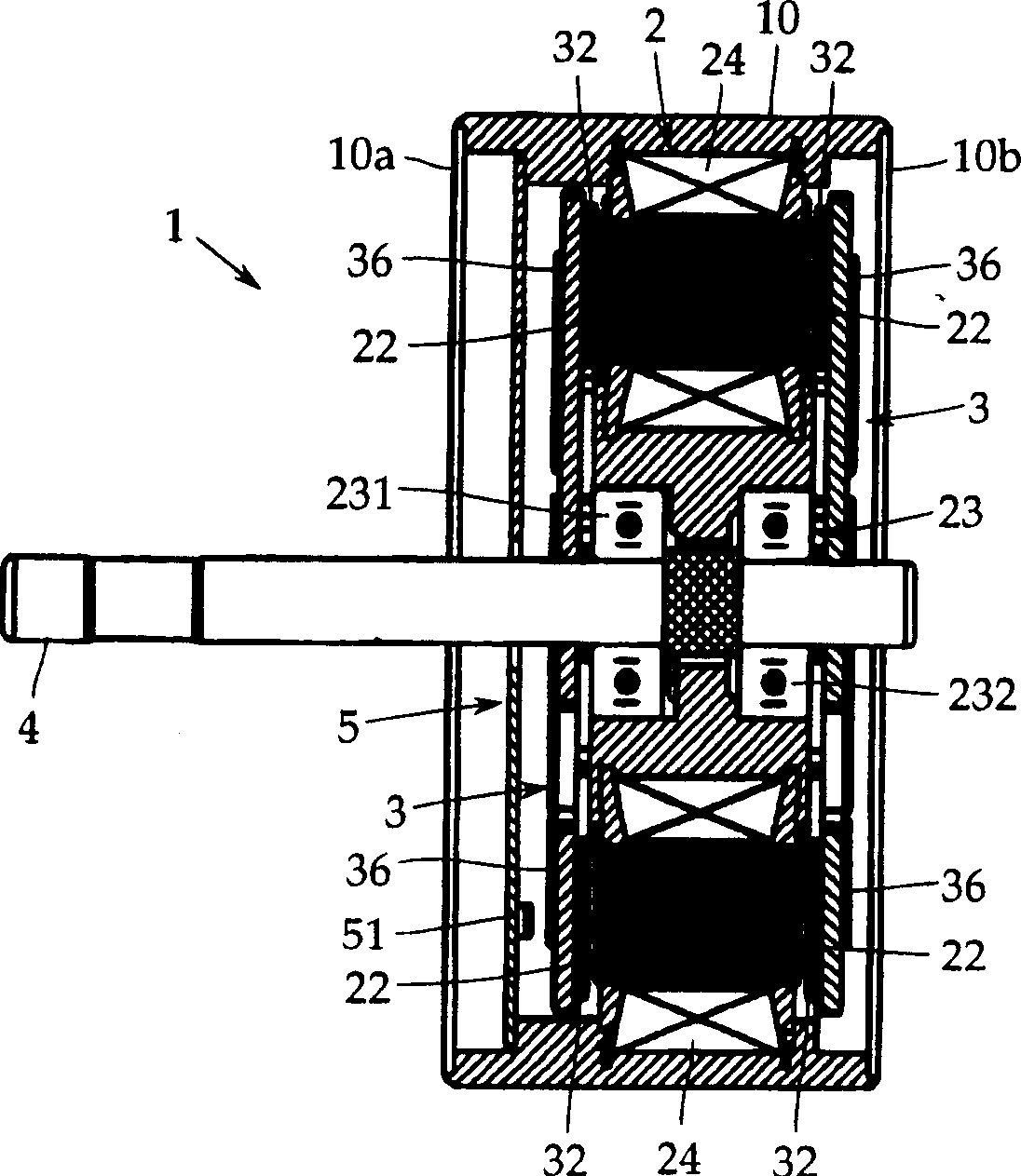

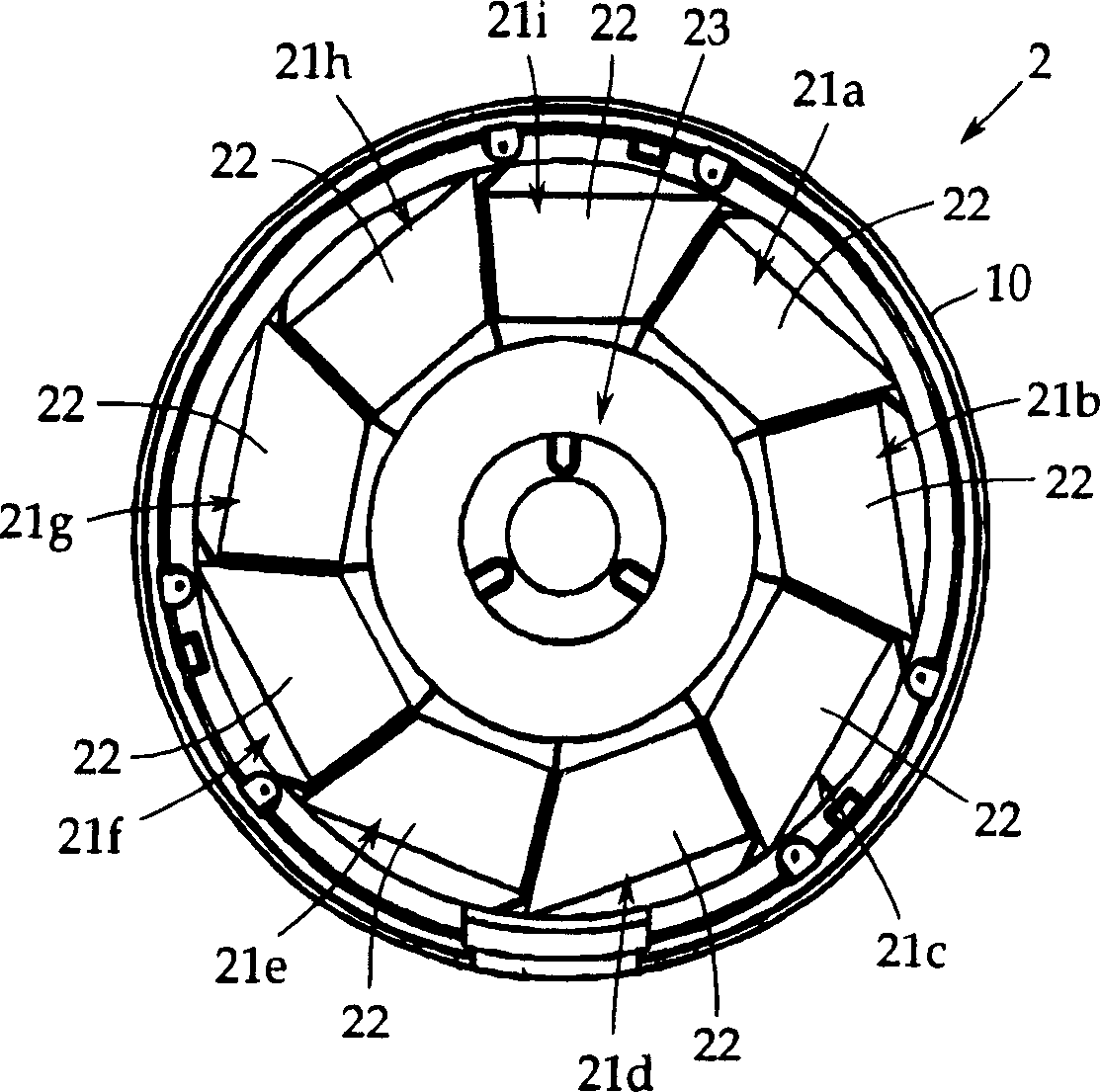

[0040] Next, embodiments of the present invention will be described with reference to the drawings. In addition, the present invention is not limited thereto. 1 is an exploded perspective view of an axial air gap motor according to a first embodiment of the present invention, figure 2 It is a central longitudinal sectional view of the first embodiment, image 3 It is a front view of a stator, and FIGS. 4A to 4C are a front view, a rear view, and an A-A line sectional view of a rotor according to the first embodiment.

[0041] This axial air-gap motor 1 includes a stator 2 formed in a disk shape, and a pair of rotors 3, 3 disposed on opposite sides of the stator 2 with a predetermined gap (gap). Each rotor 3, 3 is fixed coaxially to a rotor output shaft 4 that outputs a rotational drive force.

[0042] The stator 2 and the rotor 3 are accommodated in a cylindrical case 10 . In this example, at both ends of the housing 10, such as figure 2 As shown, disc-shaped cover member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com