Combining method of copper and aluminium alloy

A copper-aluminum alloy and diffusion alloy technology, applied in metal processing equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as high interface thermal resistance, affecting thermal conductivity, interface impedance, etc., to improve thermal conductivity and reduce manufacturing costs , The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

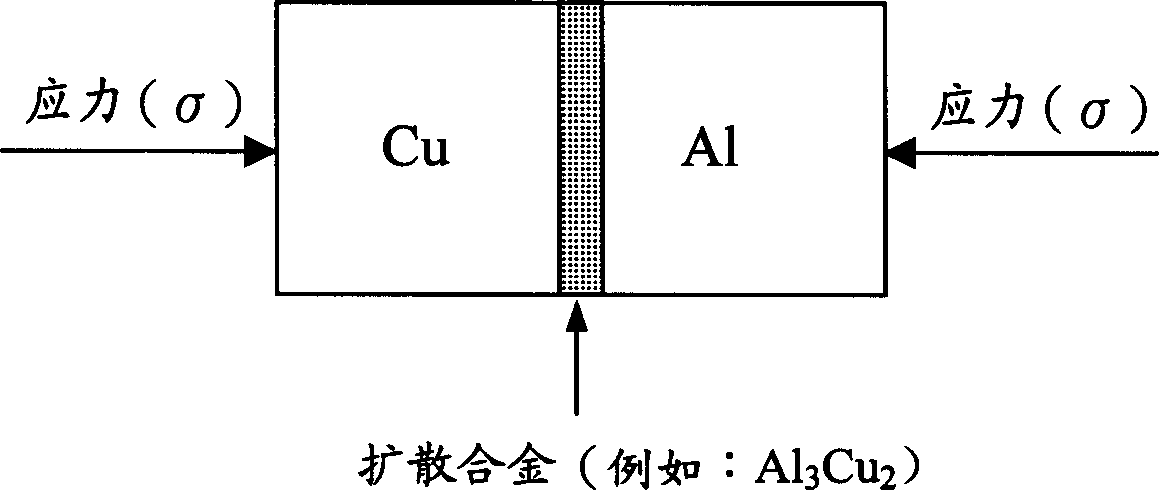

[0018] The copper-aluminum alloy bonding method of the present invention mainly overcomes the interface impedance problem when copper-aluminum alloy materials are bonded through heat treatment, thereby greatly reducing the interface thermal resistance and improving heat transfer performance.

[0019] The copper-aluminum alloy bonding method generally uses a fast-heating heating device, such as a heating furnace. The heating furnace is heated from the periphery through a resistance wire, and the maximum temperature can reach 1200 ° C. The inner material of the heating furnace is ceramics. The copper-aluminum alloy material of the present invention includes copper (Cu) material (pure copper or copper alloy) and aluminum alloy (Al) material (pure aluminum or aluminum alloy).

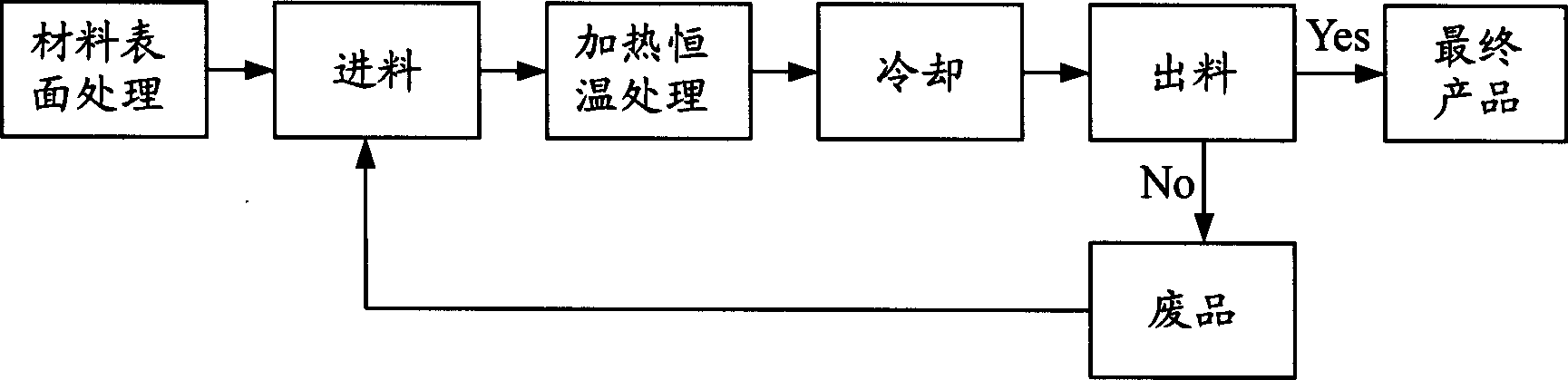

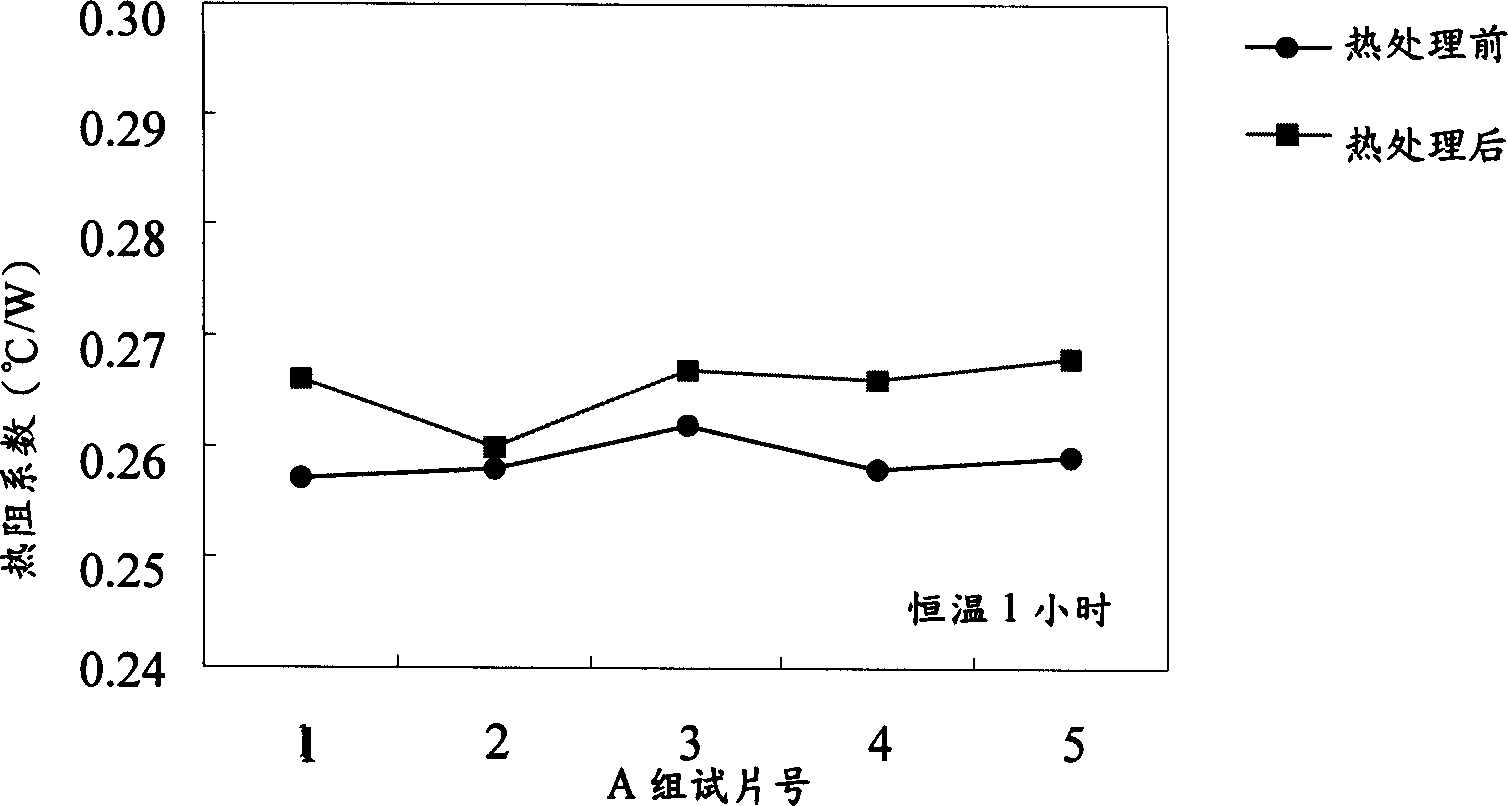

[0020] figure 1 It is a flowchart of the main steps of the copper-aluminum alloy bonding method of the present invention, figure 2 It is a schematic diagram of the copper-aluminum alloy material combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com