Manufacturing method of propyl acetate and isopropyl acetate

A technology of isopropyl acetate and its manufacturing method, which is applied in the field of acetate manufacturing, can solve the problems of waste water pollution, high manufacturing cost, and low yield, and achieve the goals of reducing manufacturing cost, improving raw material utilization, and reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

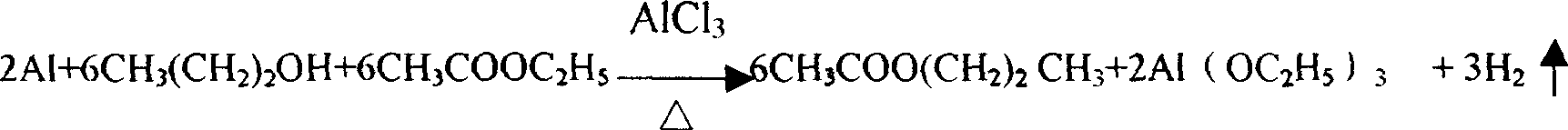

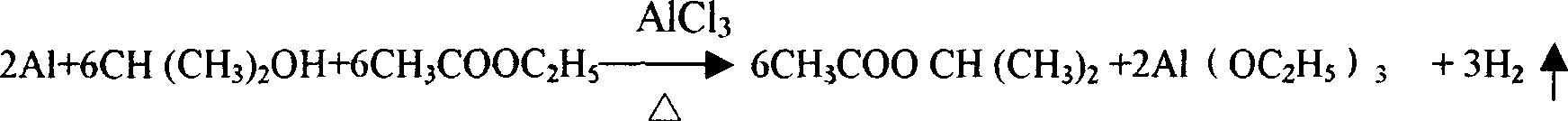

Method used

Image

Examples

Embodiment 1

[0015] In a 5-liter three-necked flask with a reflux condenser, add 0.3Kg of aluminum particles with a purity of 99%, 1.5 grams of anhydrous aluminum chloride, 2Kg of ethyl acetate solvent, then add 0.8Kg of isopropanol, stir, heat, and control The temperature of the solution is around 80°C, and after reflux reaction for 2 hours, a black mixture solution is obtained, the material is sucked out, and after 20 hours of settlement, the upper layer accounts for 98%-99% of the colorless, transparent solution, and the solution is heated to 80°C Start the distillation. With the evaporation of the solvent, the distillation temperature is gradually increased to 110°C, the heating is stopped, and the evaporation residue is cooled to obtain a mixed aluminum alcohol solid, the main components of which are aluminum ethoxide and aluminum isopropoxide. The evaporated mixed solvent was separated by two-step rectification to obtain 1100 g of isopropyl acetate finished product, with a content gre...

Embodiment 2

[0017] In a 5-liter three-necked flask with a reflux condenser, add 0.25Kg of aluminum particles with a purity of 99%, 0.28 grams of anhydrous aluminum chloride, 2Kg of ethyl acetate, and then add 0.5Kg of isopropanol, stir and heat to control the solution After 2.5 hours of reflux reaction at a temperature of about 80°C, a black mixture solution is obtained, the material is sucked out, and after 15 hours of settlement, the upper layer accounts for 98%-99% of the colorless, transparent solution, and the solution is heated to 80°C to start Distillation, with the evaporation of the solvent, the distillation temperature is gradually increased to 110 ° C, the heating is stopped, and the evaporation residue is cooled to obtain a mixed aluminum alcohol solid, the main components of which are aluminum ethoxide and aluminum isopropoxide. The evaporated mixed solvent is separated by two-step rectification to obtain 750g of isopropyl acetate product, the content of which is greater than ...

Embodiment 3

[0019] In a 5-liter three-necked flask with a reflux condenser, add 0.1Kg of aluminum particles with a purity of 99%, 6.2 grams of anhydrous aluminum chloride, 2Kg of ethyl acetate, and then add 1Kg of isopropanol, stir and heat, and control the temperature of the solution Reflux reaction at about 80°C for 3 hours to obtain a black mixture solution, suck out the material, settle after 24 hours, suck out the colorless and transparent solution with 98%-99% of the upper layer, heat this solution to 80°C to start distillation , with the evaporation of the solvent, the distillation temperature is gradually increased to 110 ° C, the heating is stopped, and the evaporation residue is cooled to obtain a mixed aluminum alcohol solid, the main components of which are aluminum ethoxide and aluminum isopropoxide. The evaporated mixed solvent is separated by two-step rectification to obtain 1250g of isopropyl acetate finished product, the content of which is greater than 99%. The main impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com