Electric car battery set unloading vehicle, and its track type battery holder and built-in type battery holder

An electric vehicle and battery assembly technology, which is applied in the direction of electric vehicle charging technology, electric power device, power device, etc., can solve the problems of unfavorable promotion and application of electric vehicles, inconvenient loading and unloading, etc., and achieve the effect of fast loading and unloading, convenient loading and unloading, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

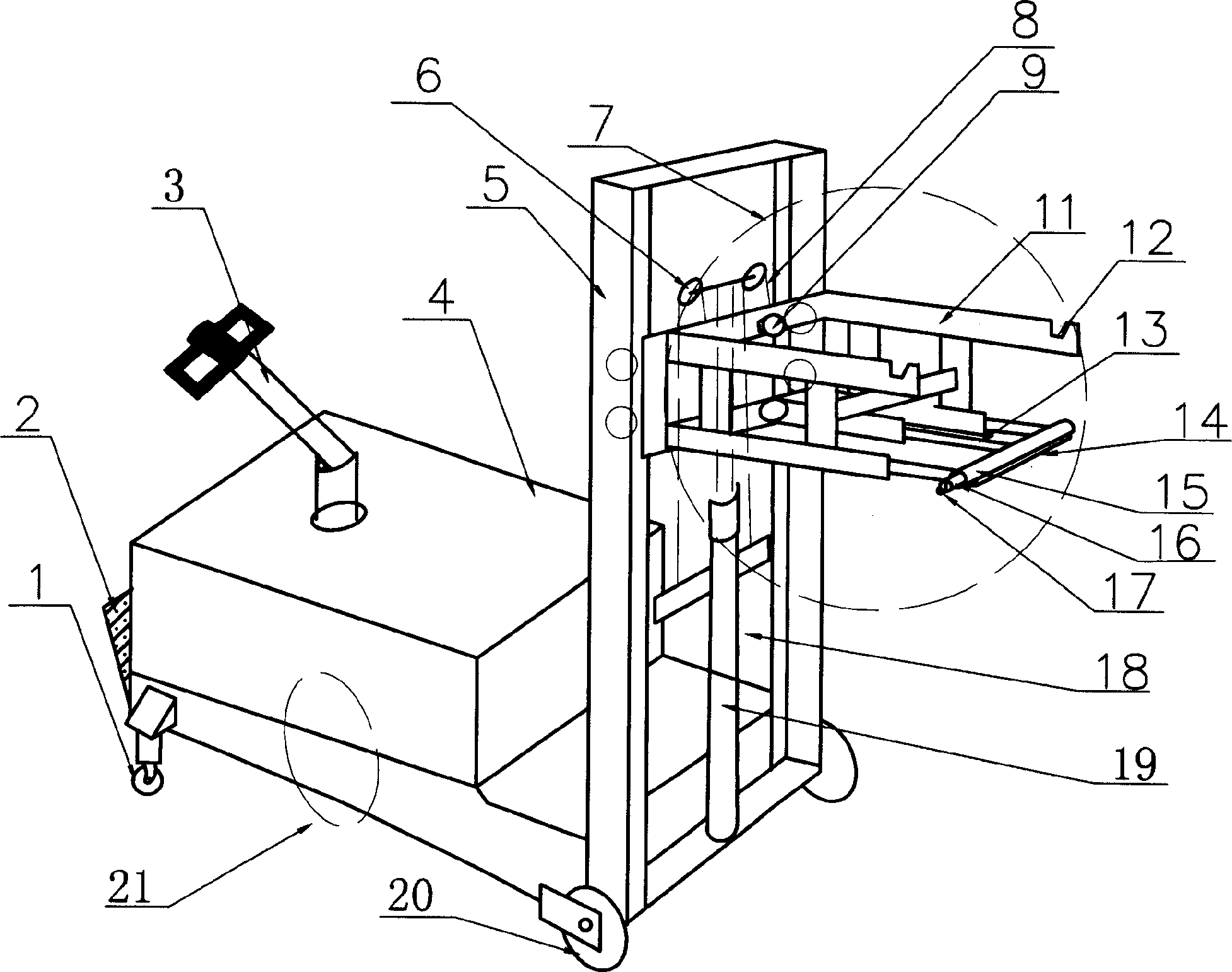

[0028] Example: such as figure 1 As shown, the battery pack quick release mechanical arm 7 is provided on the guide rail column 5 of the battery assembly and unloading vehicle, and the main lifting mechanism 18 drives the battery pack quick release mechanical arm 7 to move up and down; The supporting arm 11 is provided with a special interface 12 for cooperating with the battery frame; below the longitudinal arm 11 is provided a horizontal and vertical vertical pushing mechanism 13 and a horizontal and horizontal setting pushed by the vertical pushing mechanism 13 The telescopic cross-arm 14 is provided with a battery pack hook 17 on the telescopic cross-arm 14 .

[0029] Wherein, the longitudinal pushing mechanism 13 is a longitudinal hydraulic cylinder, and the ejector rod of the longitudinal hydraulic cylinder is connected with the telescopic cross arm 14, and the other end thereof is fixed on the battery pack quick release mechanical arm body. The main lifting structure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com