Digital metal floater flowmeter based on proportional electric capacity angle measuring principle

A float flowmeter and capacitor technology, applied in the field of flowmeter, can solve the problems of accurate measurement, mechanical structure failure, inconvenient production plant and user department, etc., and achieve the effect of reducing temperature drift index and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

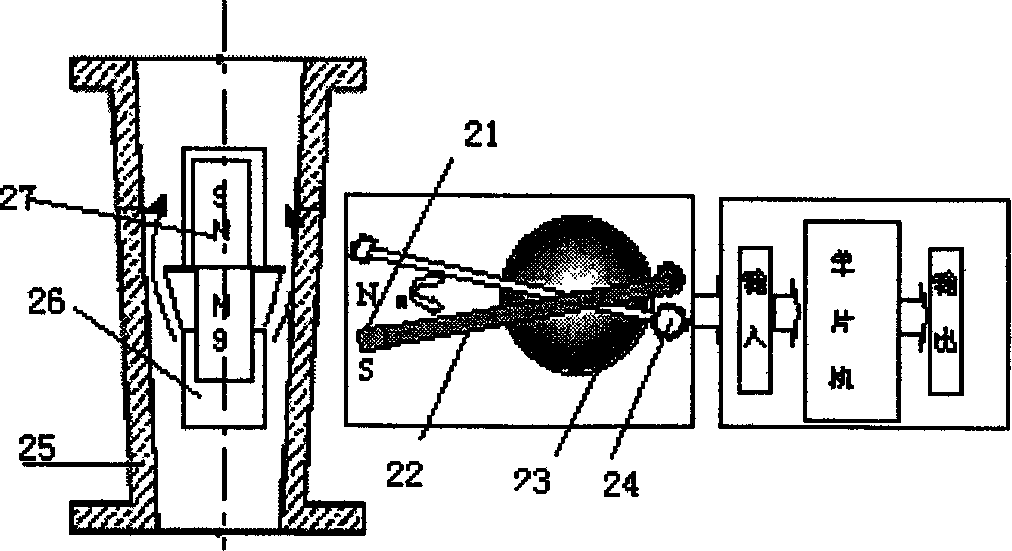

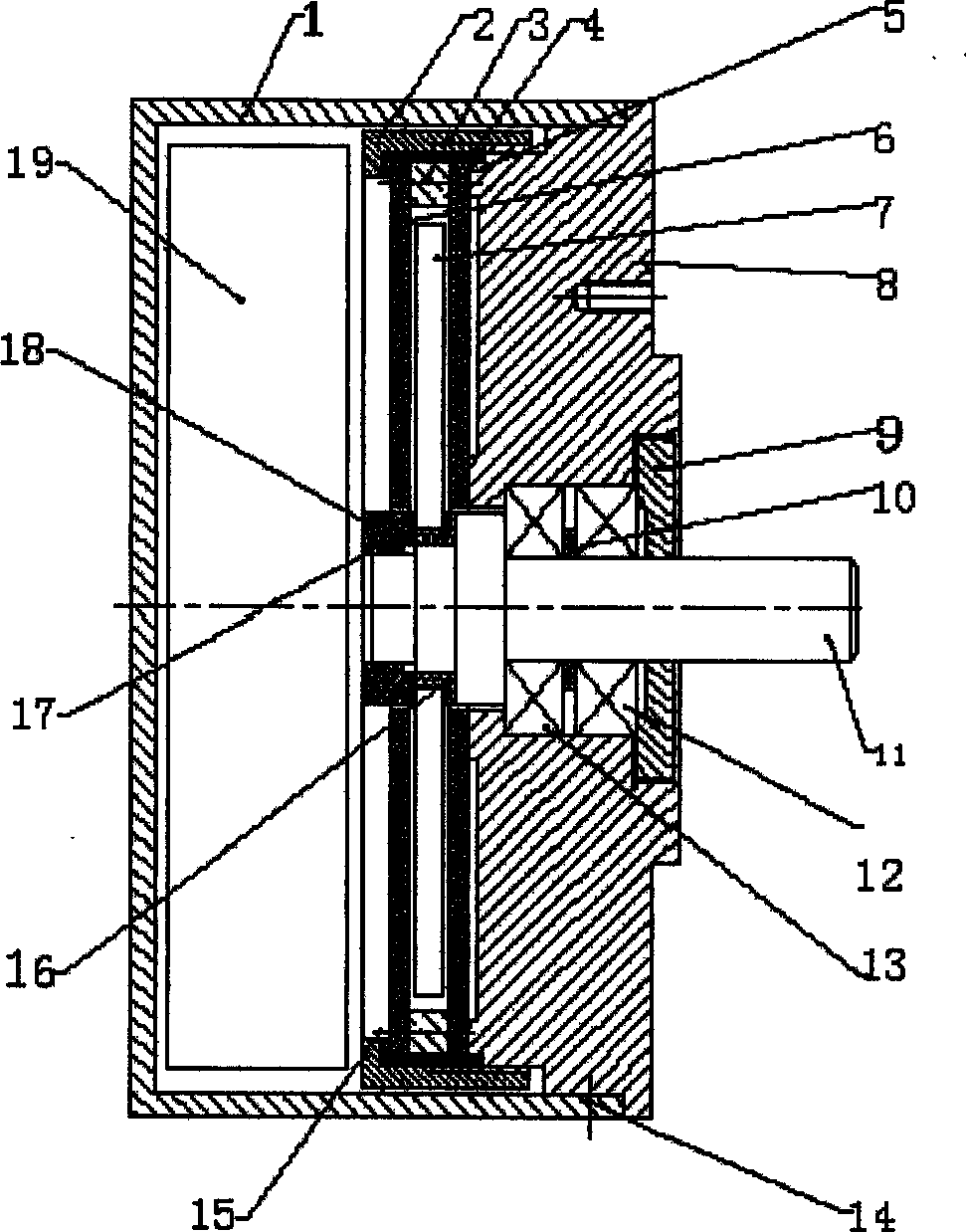

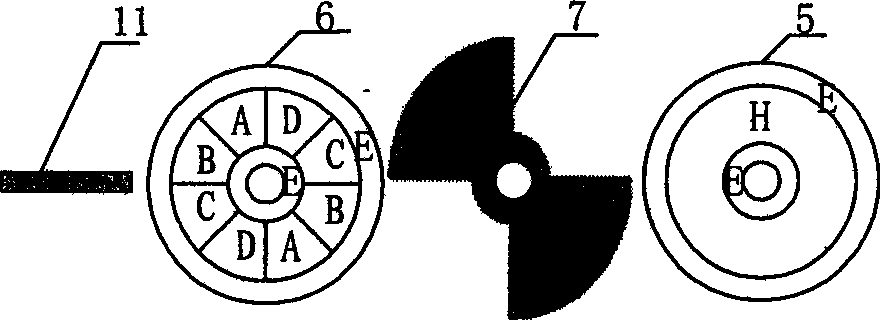

[0027] The metal float flowmeter of the present invention is composed of a float flow sensor, a converter, and an intelligent signal processor, and its structural principle diagram is shown in figure 1 . The float flow sensor includes a conical tube and a float with an inner magnetic steel arranged in the conical tube. The converter is composed of a mechanical connecting rod 22 with an external magnetic steel 21 embedded at one end and a capacitive angular displacement sensor 23. The intelligent signal processor consists of a single-chip microcomputer. and peripheral circuits. The float is placed in a vertical conical tube 25 and moves up and down as the fluid velocity changes. The float 26 is affected by gravity, buoyancy, head-flow pressure difference resistance and viscous stress. When the resultant force of the float 26 in the vertical direction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com