Membrane pipe module

A technology of modules and membrane tubes, applied in membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problem of increased cost per unit membrane area for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

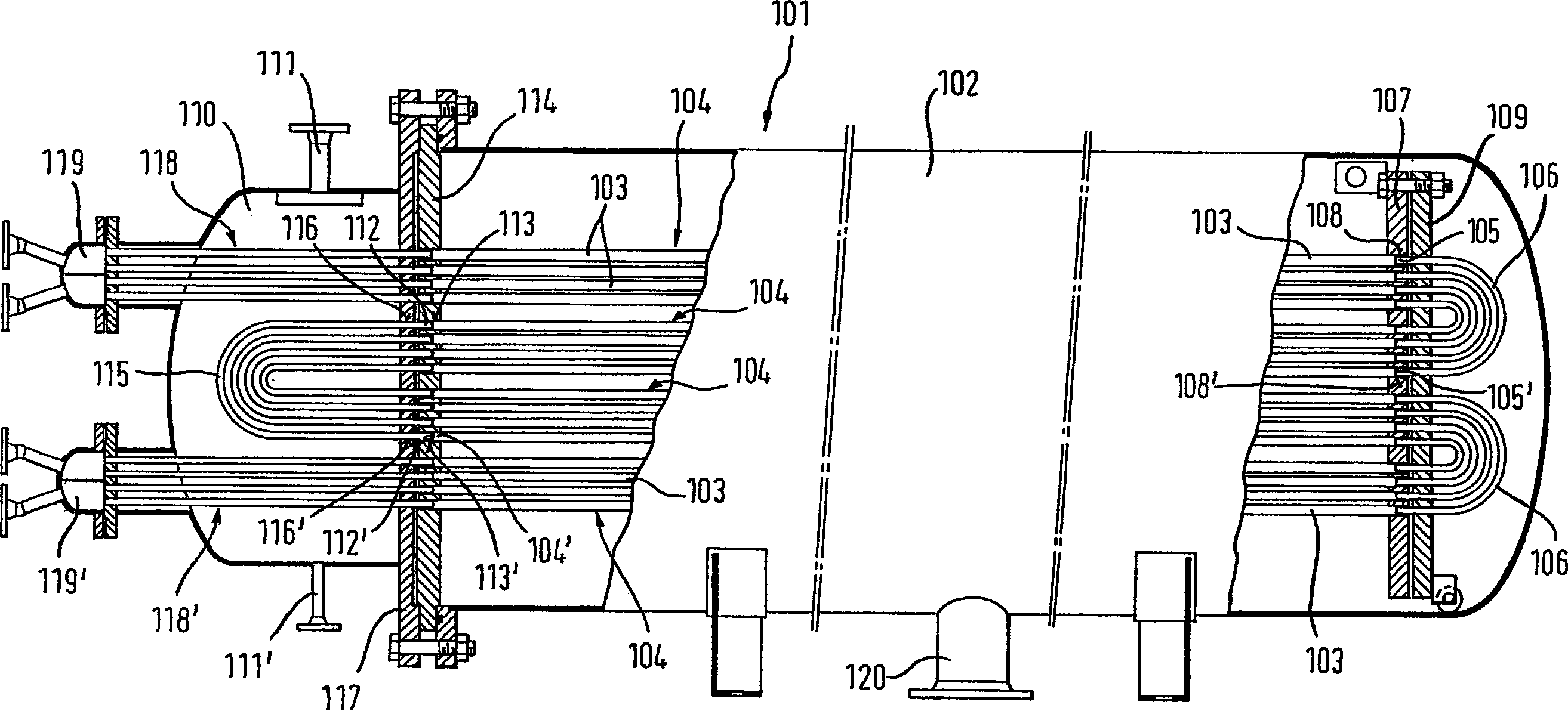

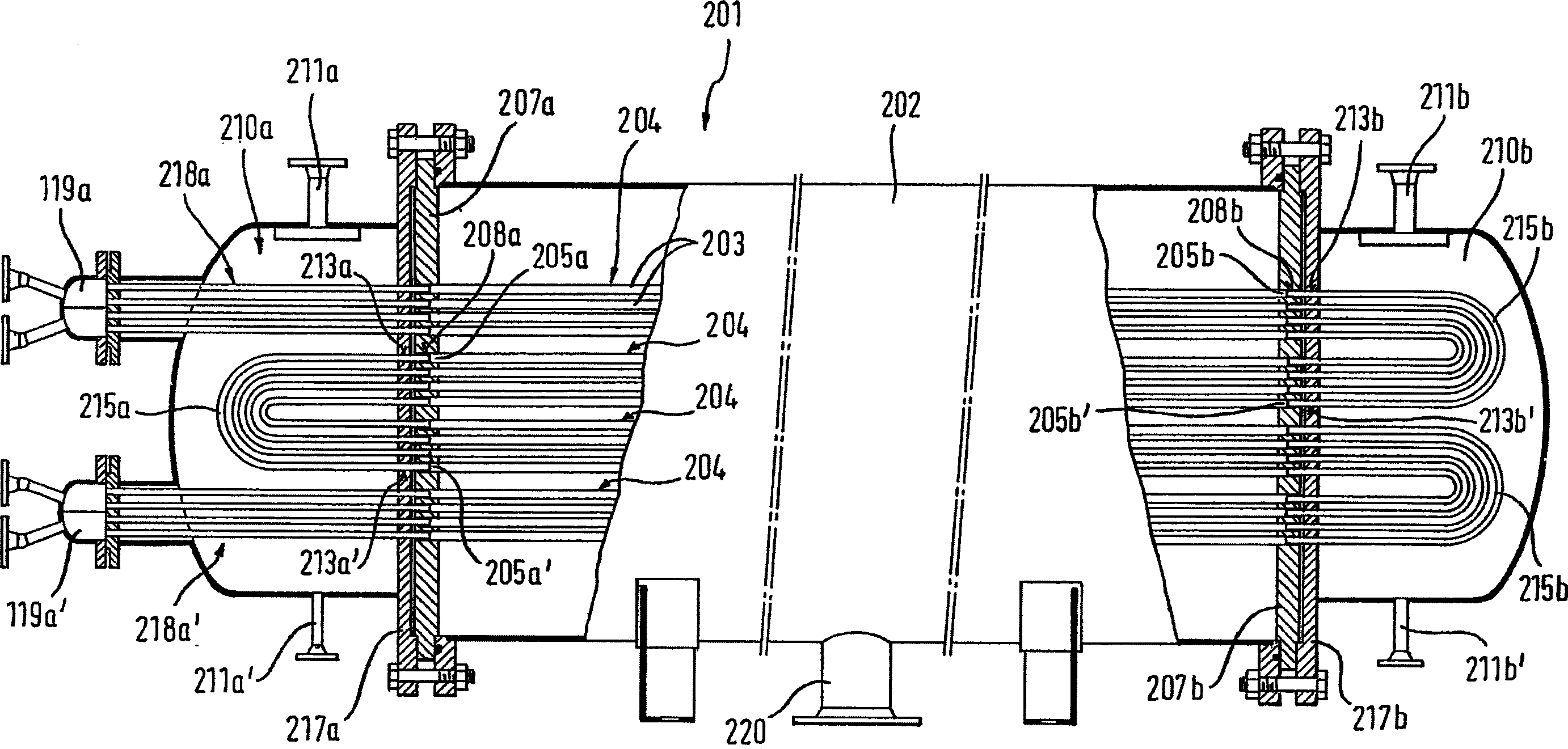

[0015] figure 1 The midtube assembly 101 has a cylindrical housing 102 containing a plurality of axially aligned support tubes 103 with tubular membrane sections 104 . In another embodiment (not shown), tubular membrane segments of sufficient compression resistance without support tubes are used. The cylindrical housing 102 is provided with at least one connection 120 for discharging the permeate that has passed through the membrane.

[0016] figure 1 Among them, on one side of the tube assembly 101, the corresponding one end 105 of the tubular membrane section 104 is fixed in the hole 108 of the separating wall 107, and is connected to the second tubular membrane section 104 fixed in the hole 108' of the separating wall 107 through a connector 106. The end 105' of the membrane segment 104'. exist figure 1 In , the connector 106 is a U-shaped tube, however it could also be a corresponding gap in the end plate 109 . Using this gap in the end plate 109, several tubular memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com