Receipt cabinet

A single cabinet and single cabinet technology, which is applied in the field of document access equipment, can solve the problems that the receipt cabinet occupies a large space and cannot be used through the wall, and achieves the effects of stable operation, reduced workload, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

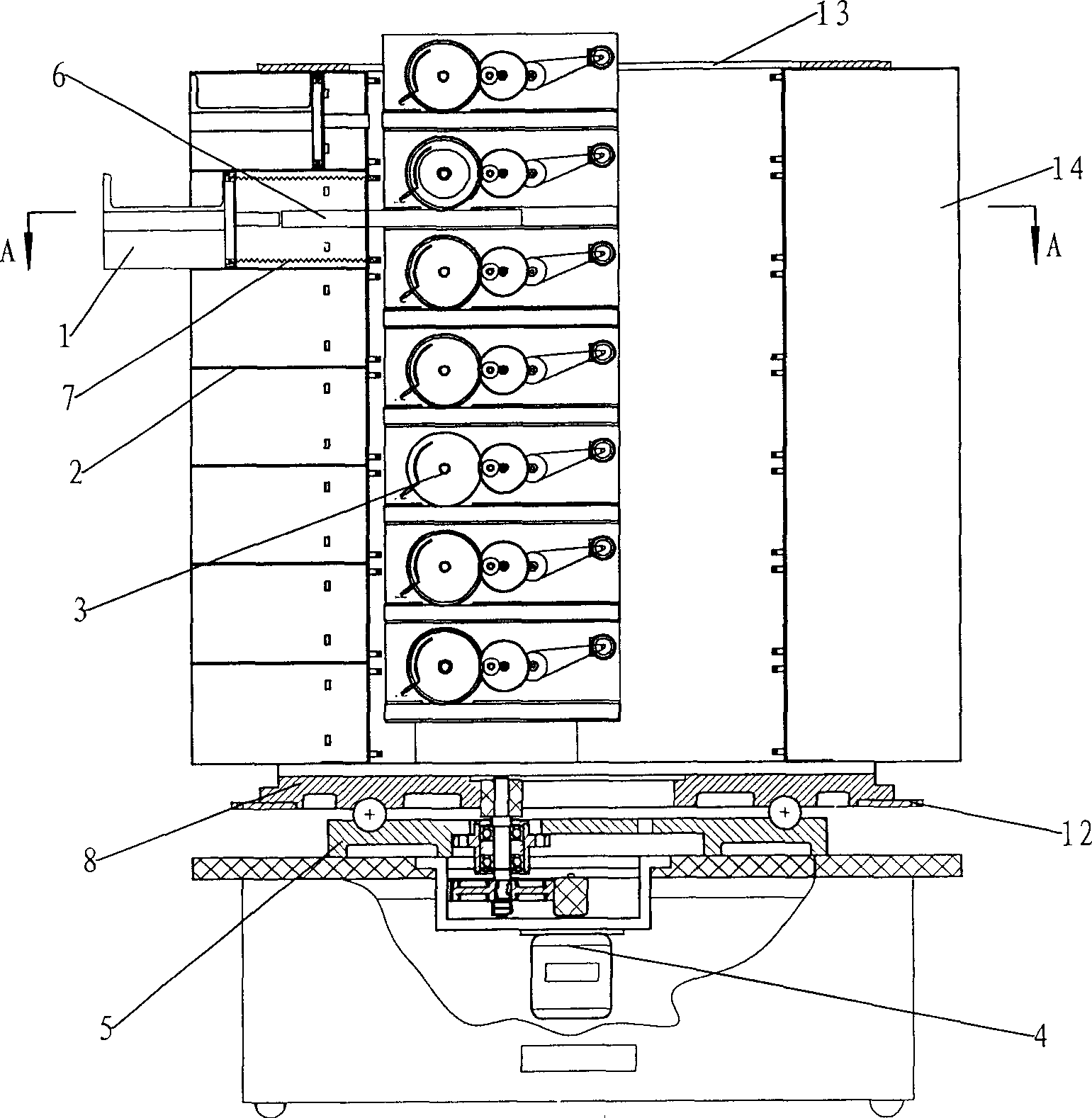

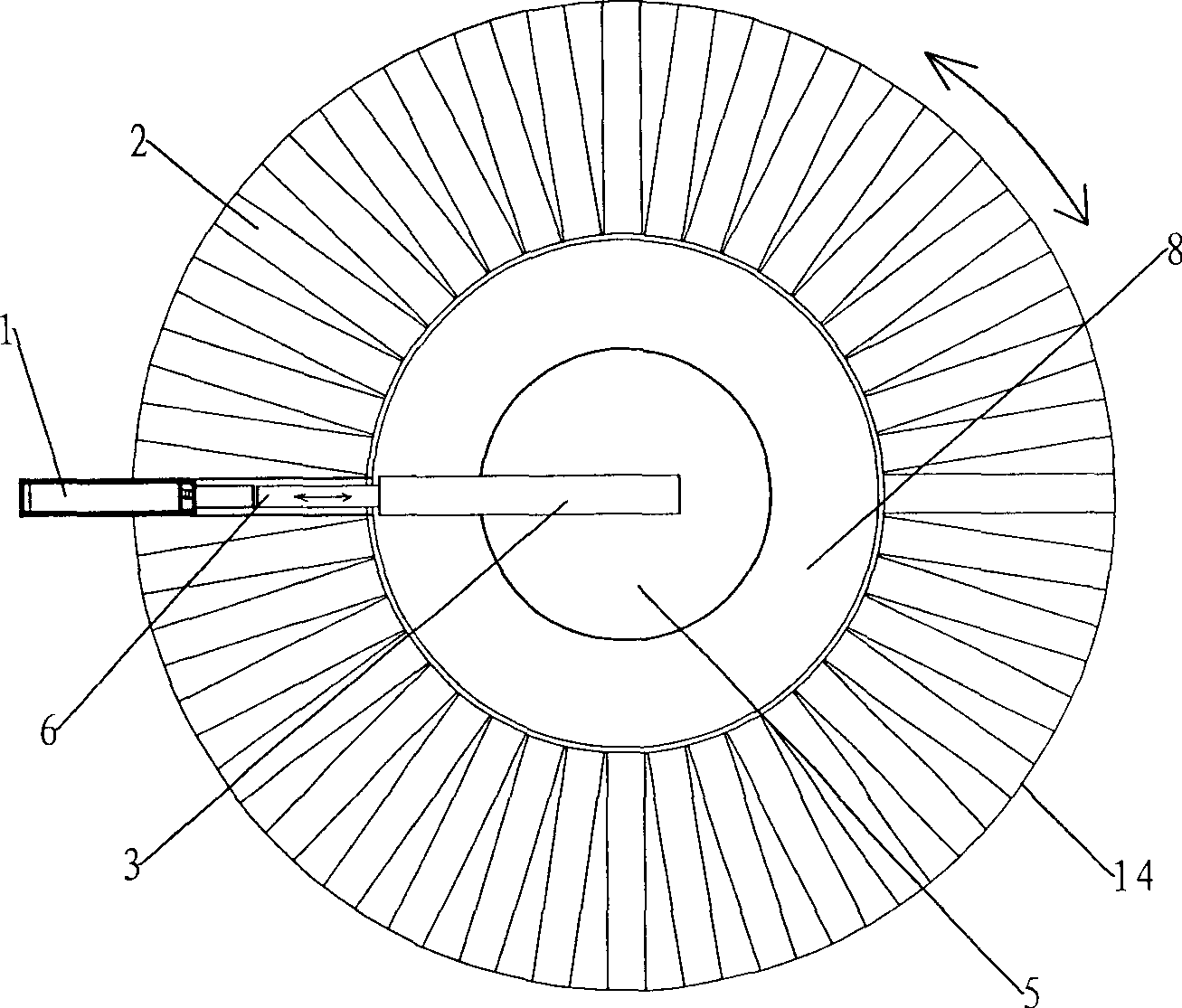

[0030] Embodiment 1: as Figure 1 ~ Figure 3As shown, the return order cabinet of the present invention includes a drawer 1 installed in a drawer box 2 and a drawer push-out mechanism 3 that pushes the drawer 1 to open and close. There are 40 drawer boxes 2 in total, and there are 7 drawers 1 in each drawer box 2, a total of 280 drawers 1. The 7 drawers 1 are vertically stacked up and down, and the drawer boxes 2 are installed on the bracket, which includes a base 5 1. The rotating base plate 8 that is arranged on the base 5 and rotates along the vertical fixed axis, the drawer box 2 is fixed on the rotating base plate 8 and arranged in a cylindrical shape around the rotation axis of the rotating base plate 8, and the top plate 13 is arranged on the top, so that the drawer box 2 is fixed Clamped between the rotating bottom plate 8 and the top plate 13, the drawer boxes 2 arranged around its circumference form a whole, as figure 1 , figure 2 As shown, a vertical revolving si...

Embodiment 2

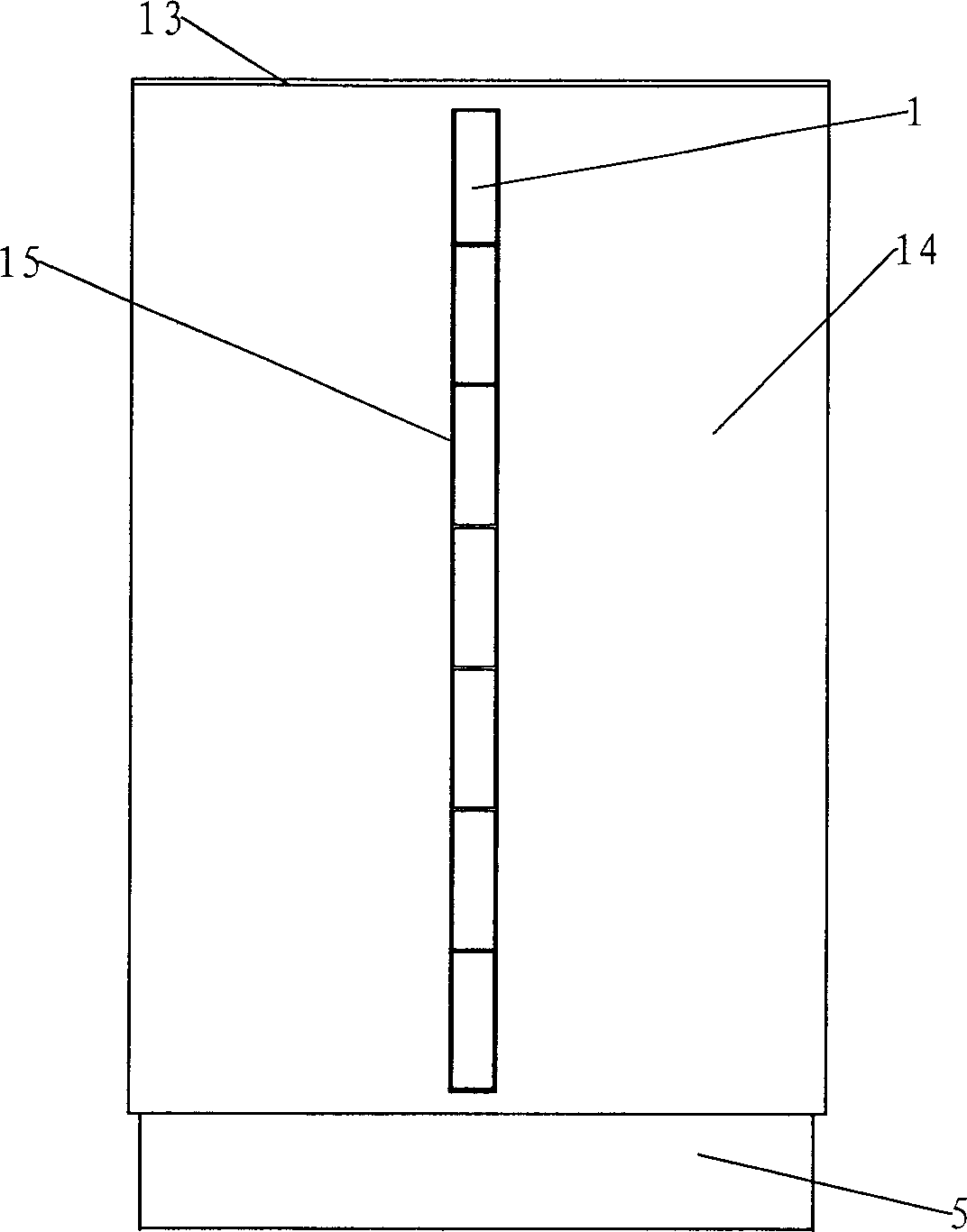

[0035] Embodiment 2: as Figure 4~6 As shown, the return order cabinet of the present invention includes a drawer 1 installed in a drawer box 2 and a drawer push-out mechanism 3 that pushes the drawer 1 to open and close. There are 32 drawer boxes 2, and 8 drawers 1 are arranged in each drawer box 2, a total of 256 drawers. The direction in which the drawers 1 are arranged is that the left and right are stacked horizontally, and the drawer box 2 is installed on the support. The support includes a base 5, a horizontal shaft 10 arranged on the base 5, and a lantern-shaped shaft that is fixed on the horizontal shaft 10 and rotates along a horizontal fixed axis. The frame 9 and the drawer box 2 are fixed on the lantern-shaped frame 9 and arranged in a cylindrical shape around the rotation axis of the lantern-shaped frame 9, thereby forming a horizontal rotary single cabinet.

[0036] The drawer push-out mechanism 3 is arranged between the drawer box 2 and the drawer 1 so as to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com