Proportional control valve for lifting height of nozzle

A technology of proportional control valves and nozzles, which is applied in the direction of valve lifts, valve details, valve devices, etc., which can solve the problems of affecting the response speed, not being able to adapt to the rapid change of fountain water shape, and increasing the cost, so as to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

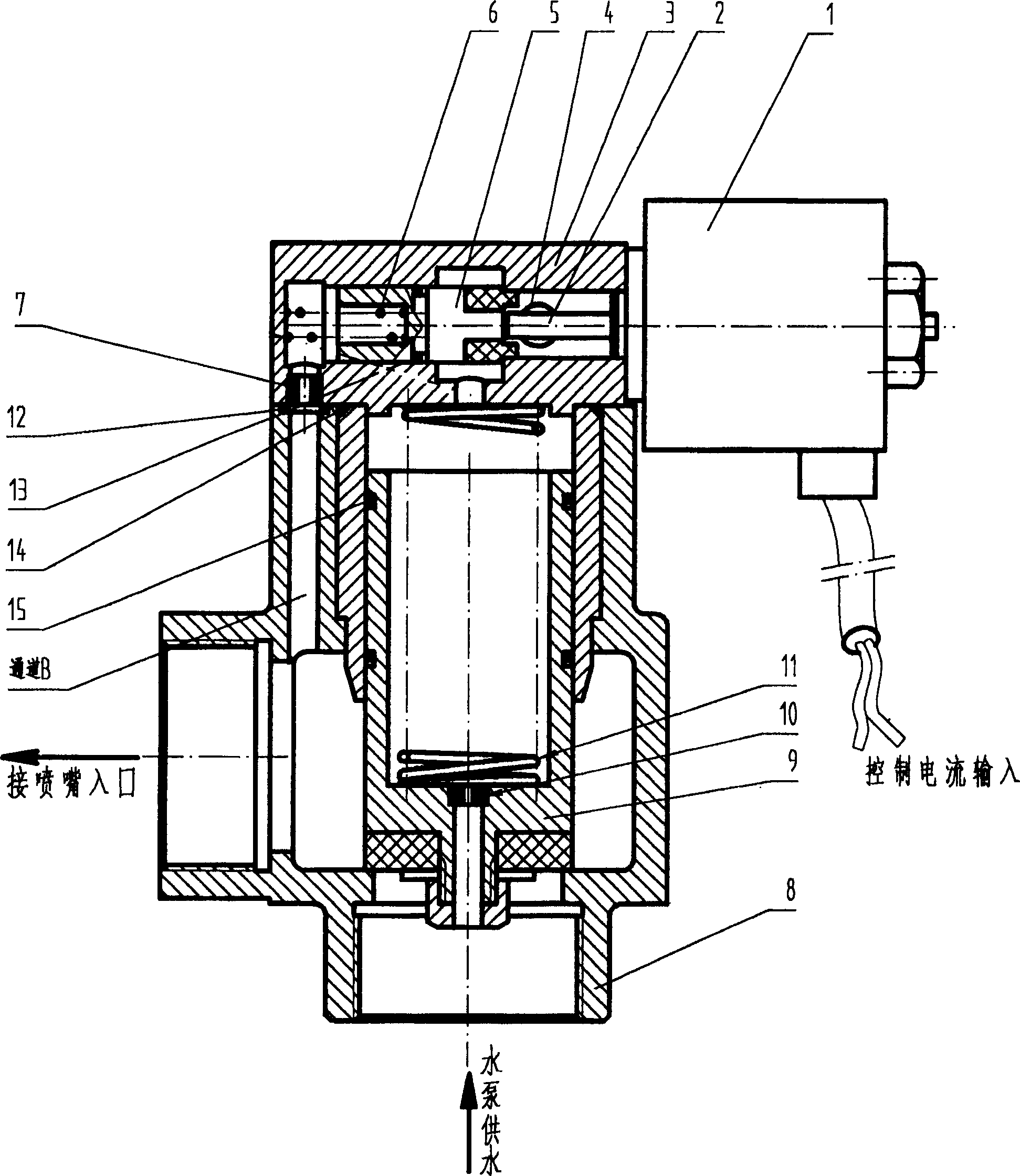

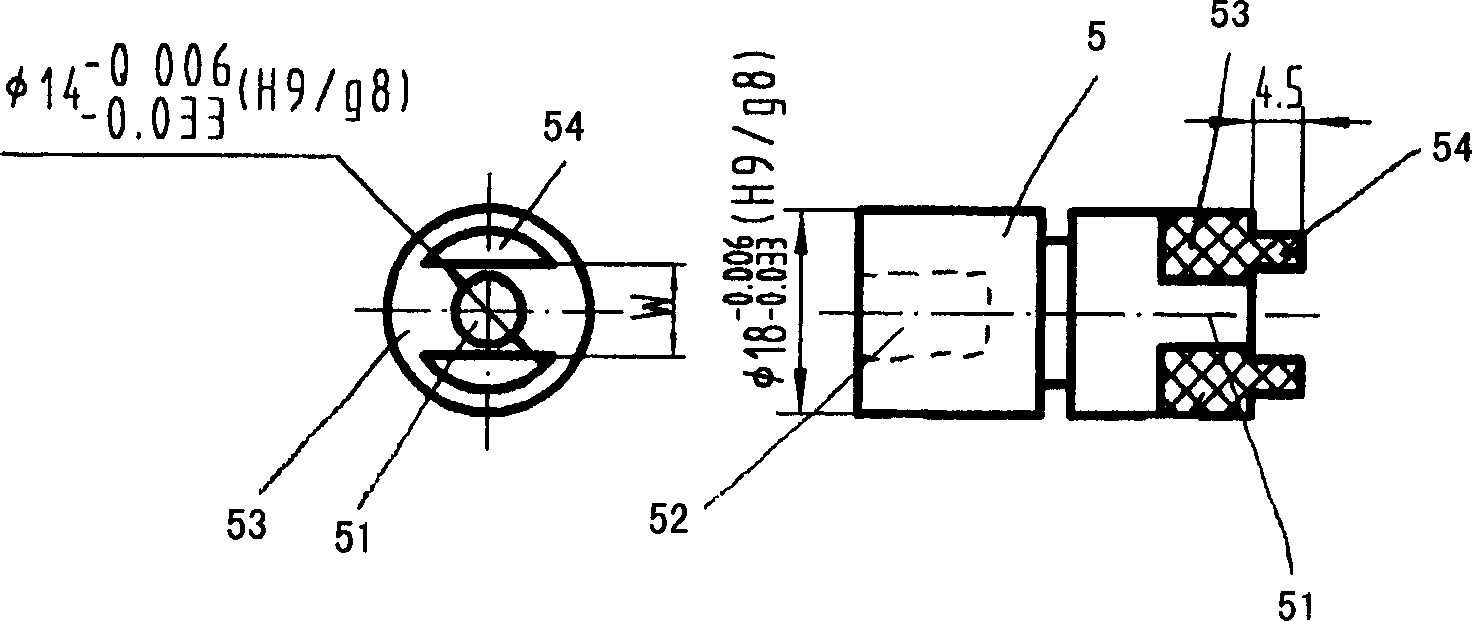

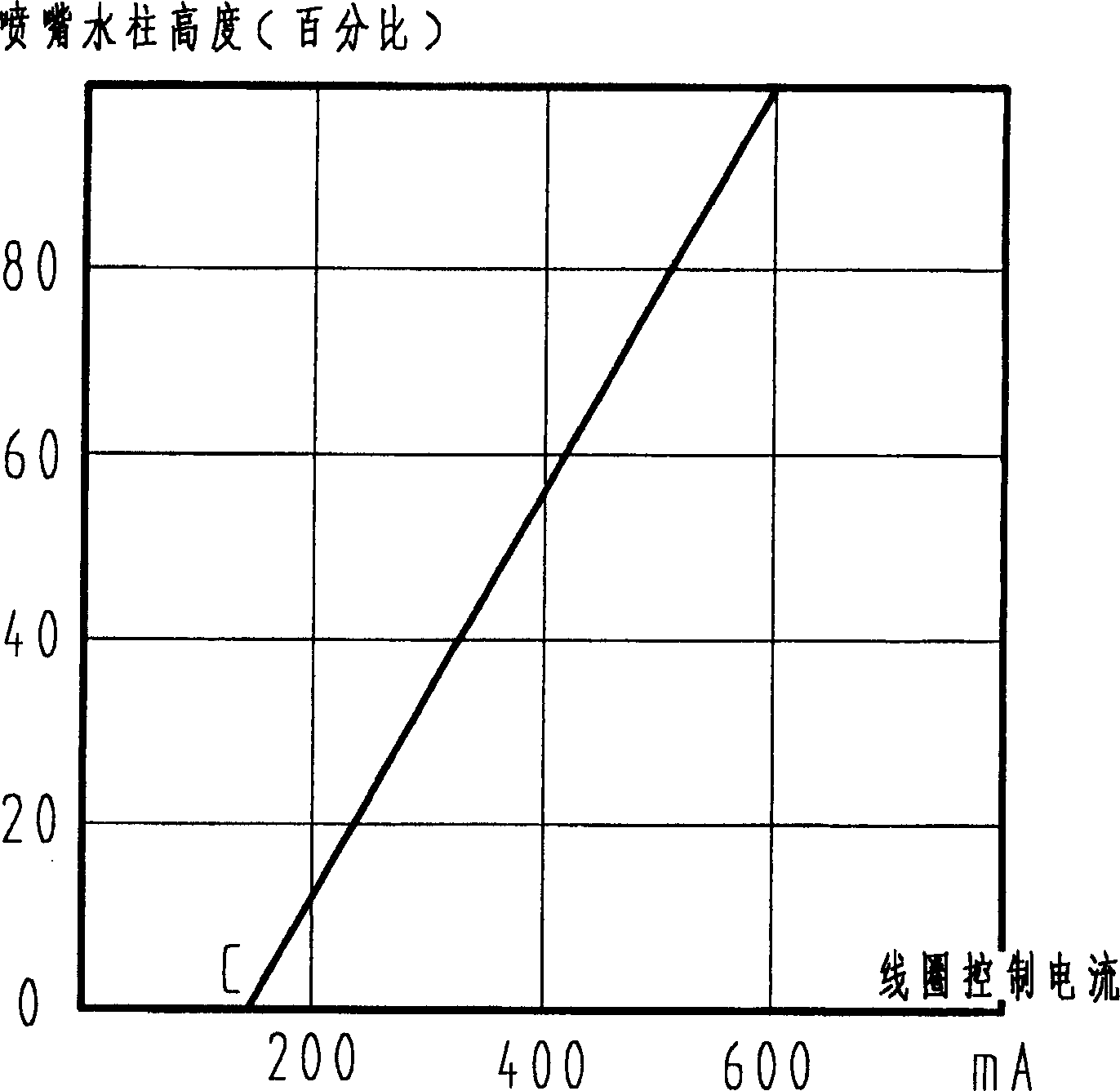

[0018] The technical scheme adopted by the present invention is: it is known that the height of the water column at the outlet of the nozzle is directly proportional to the pressure of the water flow at the inlet of the nozzle. Based on this, it can be inferred that continuous adjustment of the water column height can be achieved by continuously adjusting the water flow pressure at the nozzle inlet. The proportional control valve of the present invention is connected in series between the water supply electric pump and the nozzle, the inlet of the proportional control valve is connected with the outlet of the submersible electric pump, and the outlet of the proportional control valve is connected with the nozzle inlet. The proportional control valve is composed of two non-leakage valves (seat valves) with different diameters. The pilot seat valve with a smaller diameter has the functions of comparator and pilot hydraulic amplification. One end of the pilot valve is controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com