Drilling apparatus

一种钻井、设备的技术,应用在改进的钻井设备领域,能够解决笨重等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

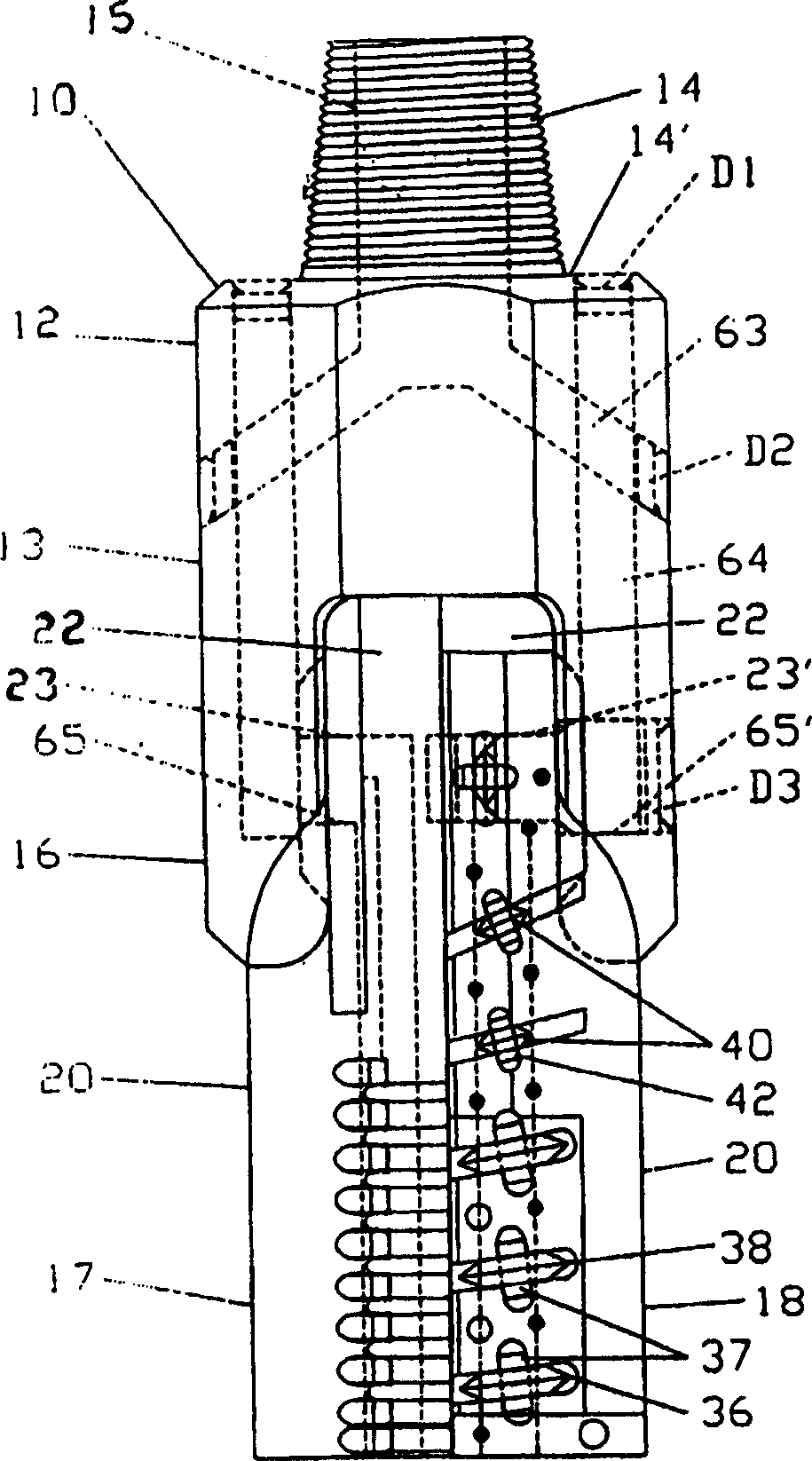

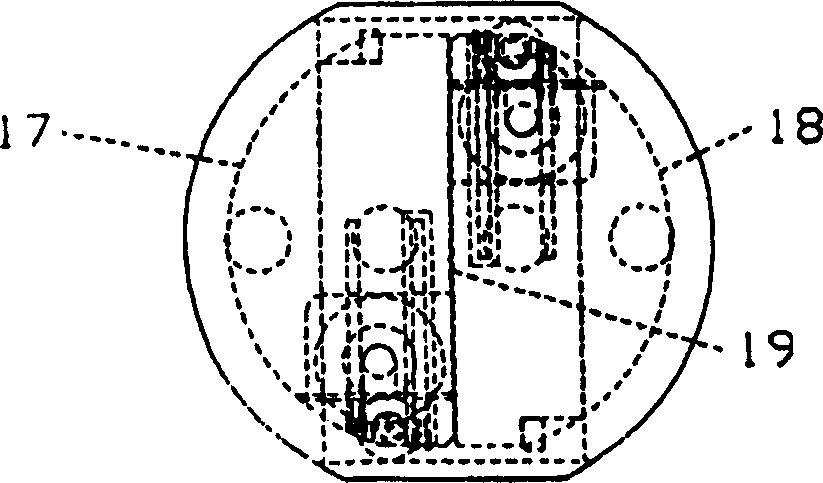

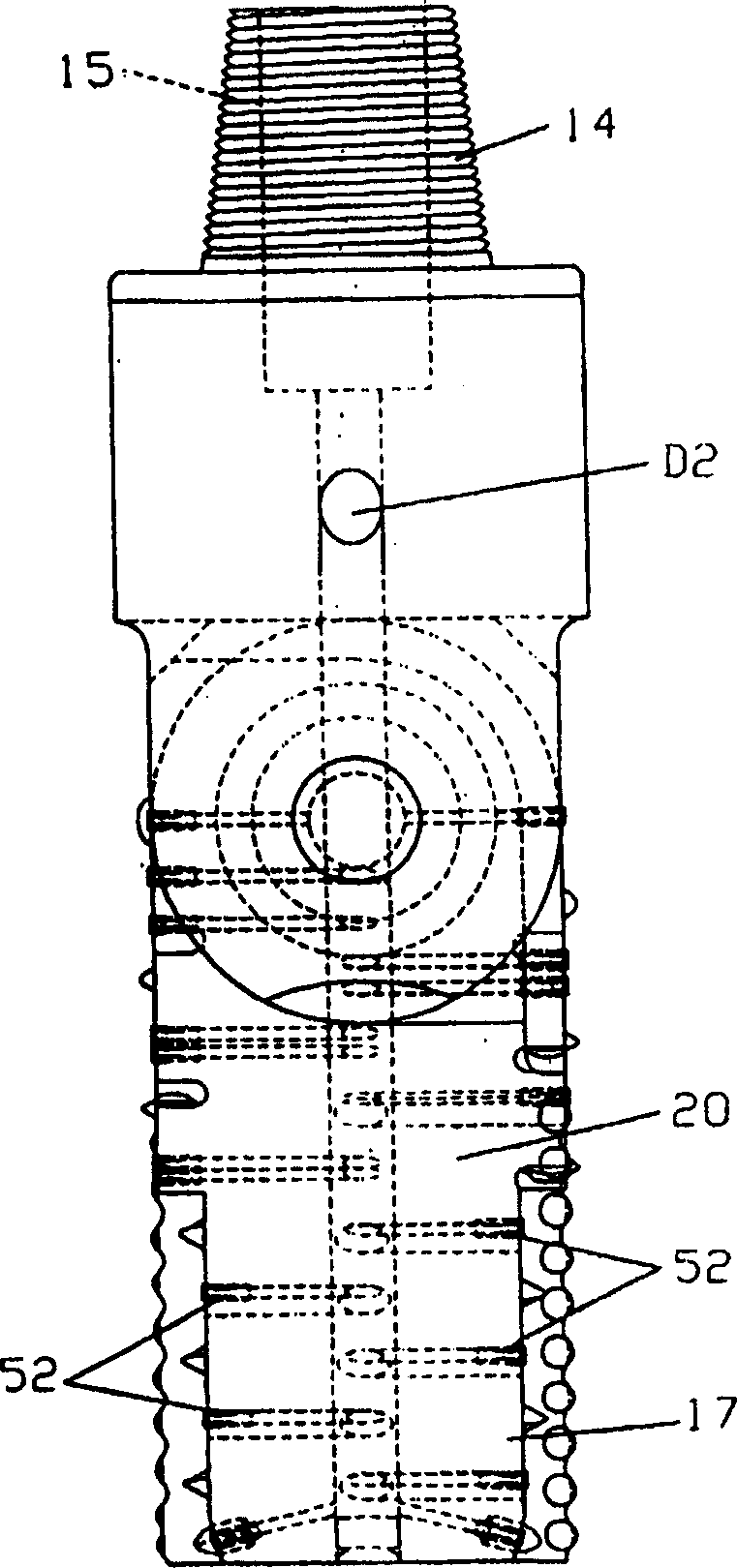

[0022] Refer to the accompanying drawings for details, Figure 1 to Figure 4 A drill bit assembly 10 is shown by way of example, comprising a sub 12 in the form of a hollow cylindrical blade support 13 having an upper threaded end 14 and a lower forked pivot end 16 . A pair of cutting blades 17 and 18 each consist of an elongated blade arm 20 tapering to a circular pivot end 22 having transverse holes 23, 23' for pivotal connection to the The lower pivoting end 16 of the blade support 13 . Each blade arm 20 is of generally semicircular configuration and has a flat facing surface portion 19 . Thus, the blades 17 and 18 are supported in a substantially longitudinally extending first position when at rest and when performing as figure 1 and Figure 4 The pivoting movement between the transverse and mutually perpendicular directions respectively during operation is shown. This pivot end 16 has the form of an ear or extension of a hollow cylinder, so that it is arcuate in secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com