Steel pipe roof jacking construction method

A construction method and technology of steel pipes, which are applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as inability to adapt to the requirements of large-section tunnels in buildings, and achieve the effects of reduced surface settlement, safe construction, and small environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

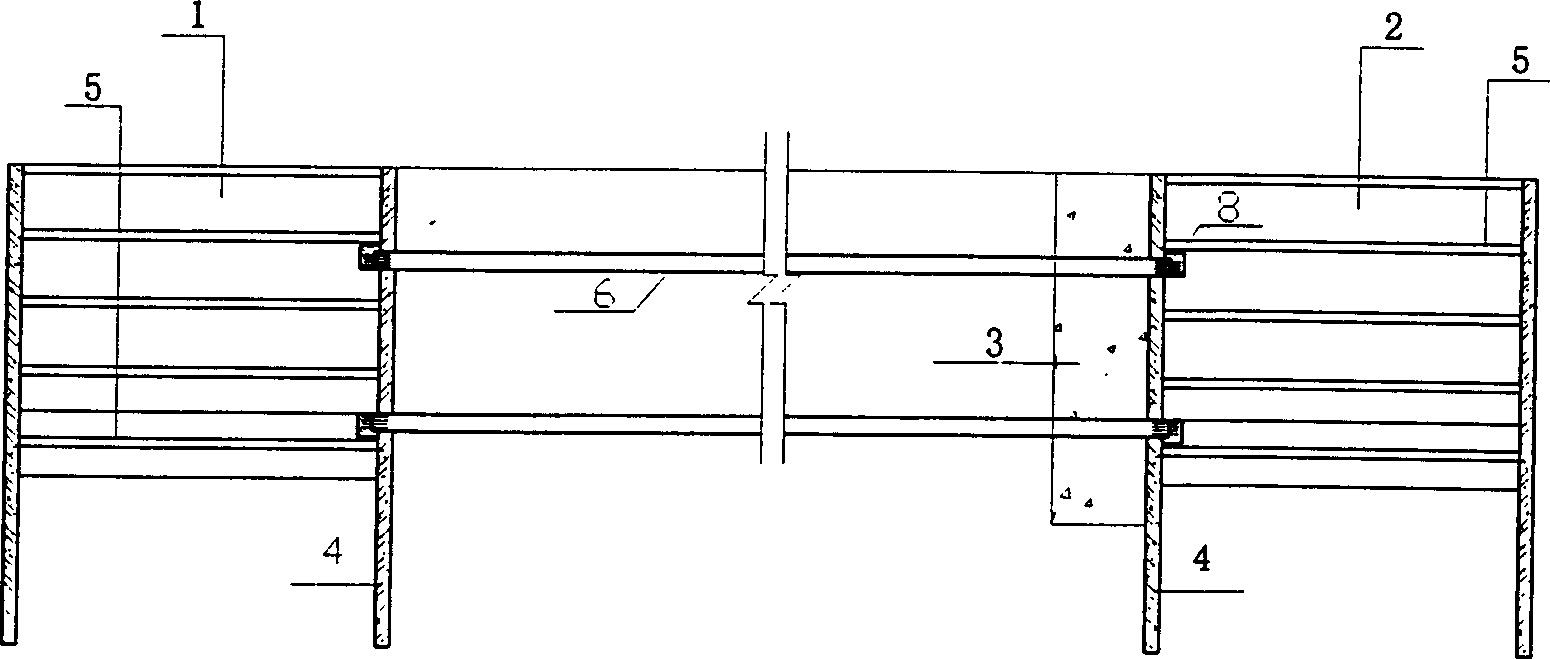

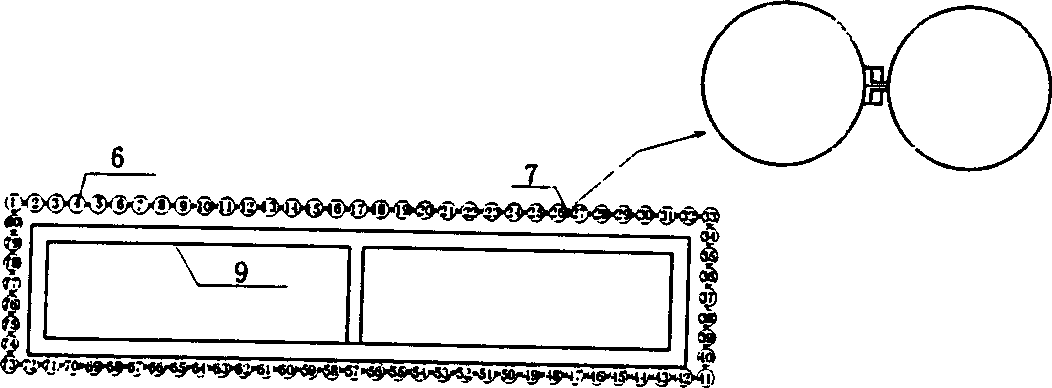

[0037] Take the construction of an overpass tunnel under a certain road in a certain city as an example. The tunnel is located in a soft soil stratum in a certain city. The surface environment protection requirements are strict, and it is a large-section underground project. It is constructed by the pipe curtain box culvert jacking method. 34.2 meters x 7.85 meters, the pipe curtain section is about 125 meters long, and 80 φ970 steel pipes are connected through locks to form an enclosure structure with a zigzag cross section. The specific implementation steps are as follows:

[0038] 1. Excavate two working wells 1 and 2 on both sides of the proposed pipe curtain. The project is in a north-south direction, with the departure well 2 on the north side and the receiving well 1 on the south side. The details are as follows: Firstly, the diaphragm wall 4 of the working well is constructed, and an underground diaphragm wall with a thickness of 800mm is used as the enclosure structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com