Terminal manufacturing method and its product

A manufacturing method and terminal technology, applied in the direction of contact manufacturing, contact parts, etc., can solve problems such as terminal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

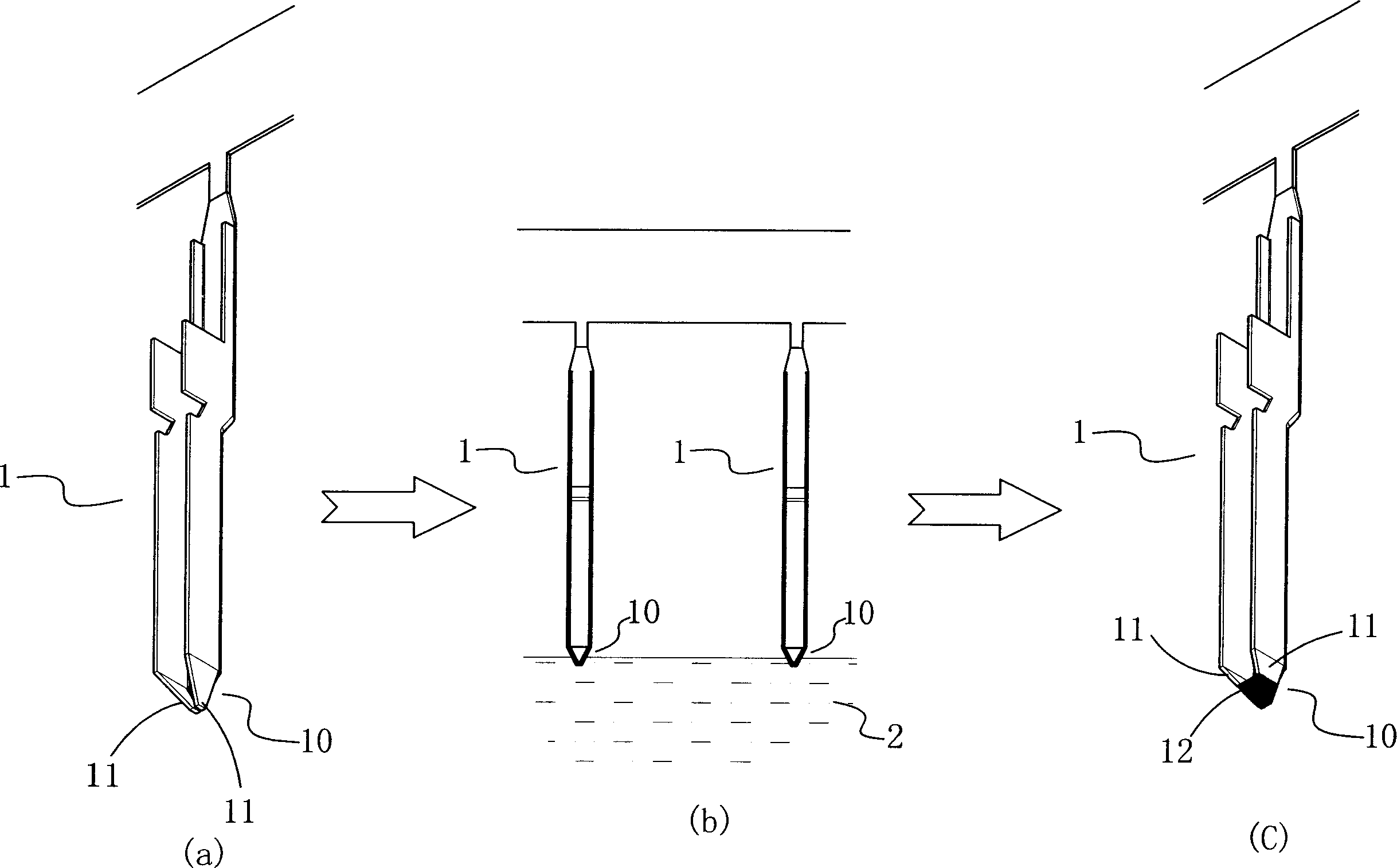

[0028] see figure 1 , is the first preferred embodiment of the present invention, and its steps are as follows:

[0029] Such as figure 1 As shown in part (a), a terminal 1 is punched and formed on a conductive metal sheet, and an end 10 of the terminal 1 has a plurality of pieces 11, and these pieces 11 are formed into a cone shape together.

[0030] Next, if figure 1 As shown in part (b), the end 10 of the terminal 1 is immersed in a conductive thermoplastic solution 2, so that the thermoplastic solution 2 is attached to the end 10 of the terminal 1, wherein the thermoplastic solution 2 is to choose one from the group consisting of conductive rubber solutions and conductive metal solutions, preferably solder or other conductive metal solutions with similar properties.

[0031] Finally, if figure 1 As shown in part (c), the end 10 of the terminal 1 leaves the thermoplastic solution 2 . After the thermoplastic solution 2 attached to the end portion 10 is cooled and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com