Co-extrusion sheet material extruding equipment

An extrusion equipment and sheet technology, applied in the field of co-extrusion sheet extrusion equipment, can solve the problem that the sheet cannot effectively meet the demand, and achieve the effects of good performance, loss avoidance, and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

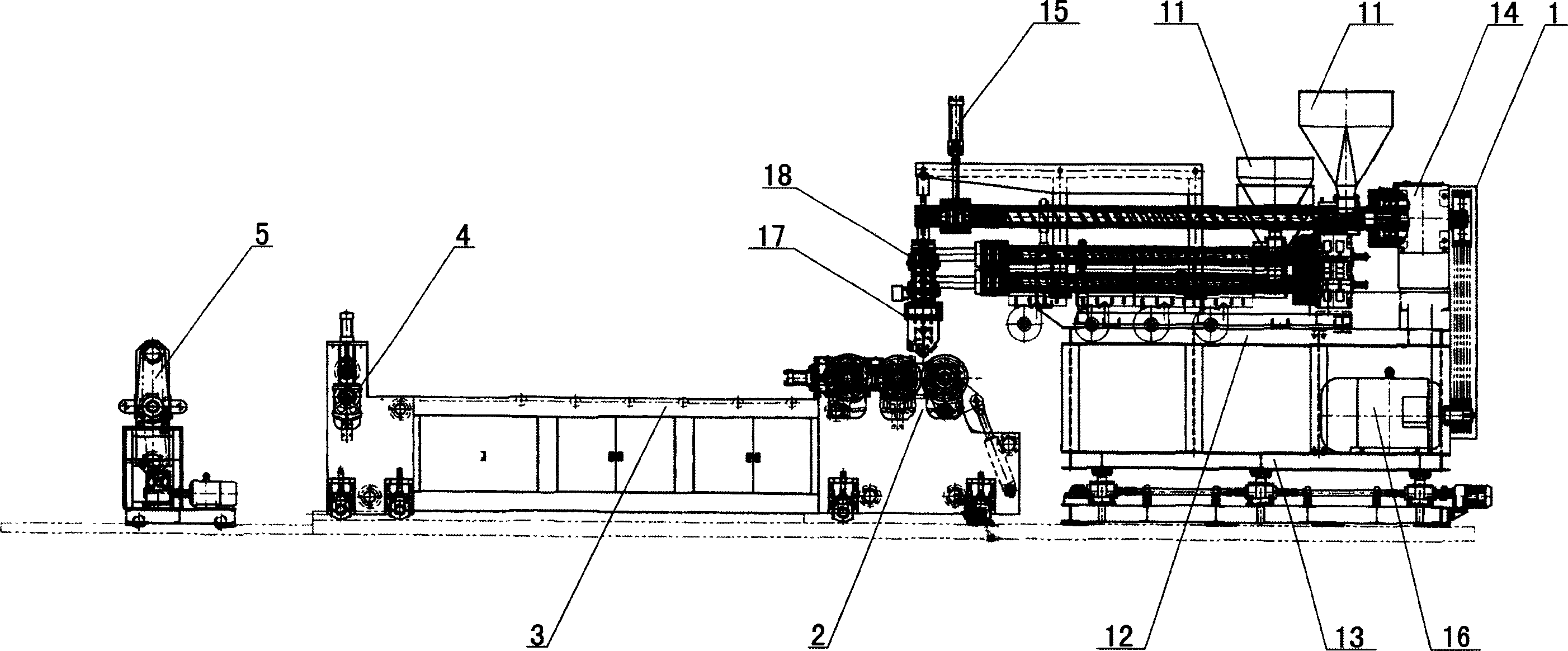

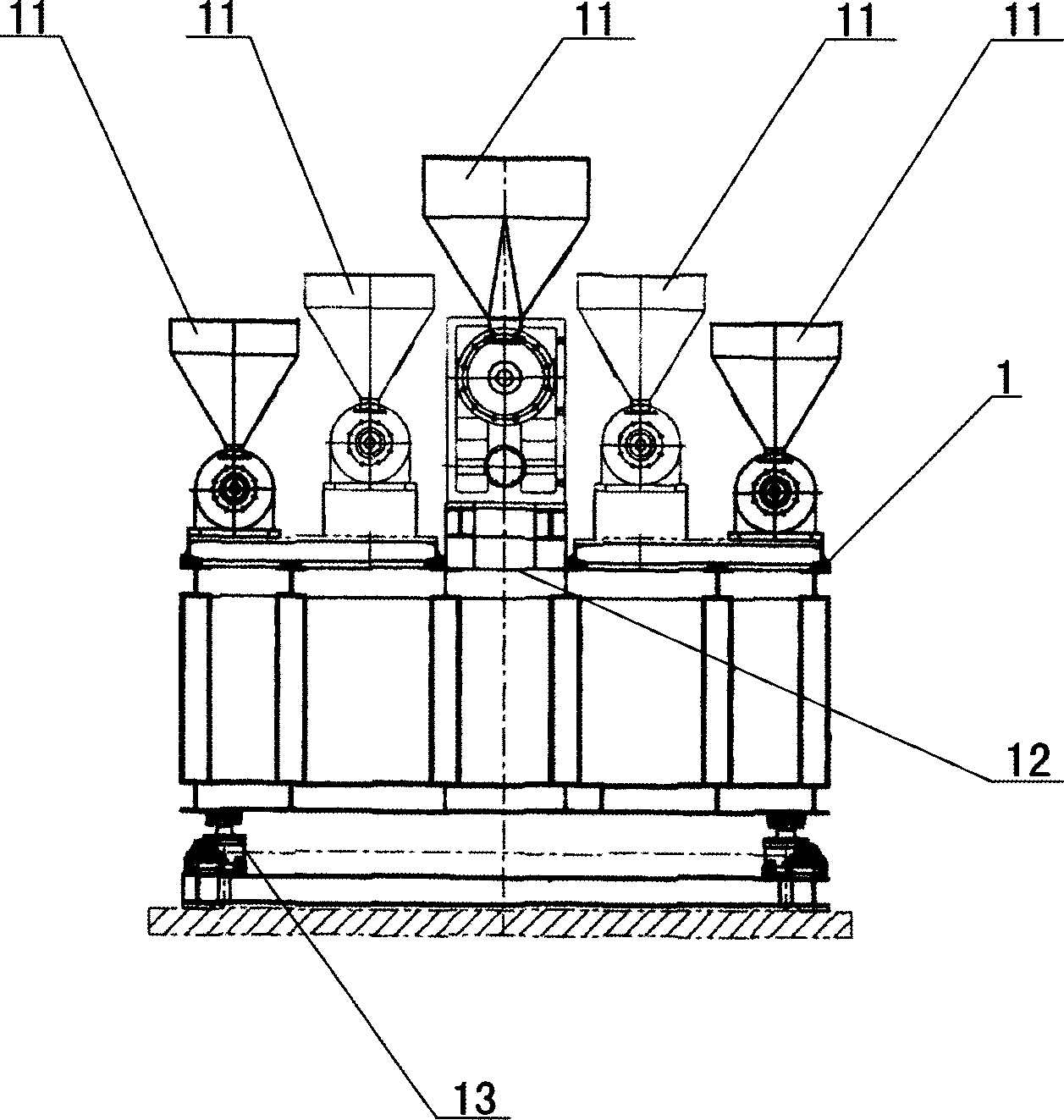

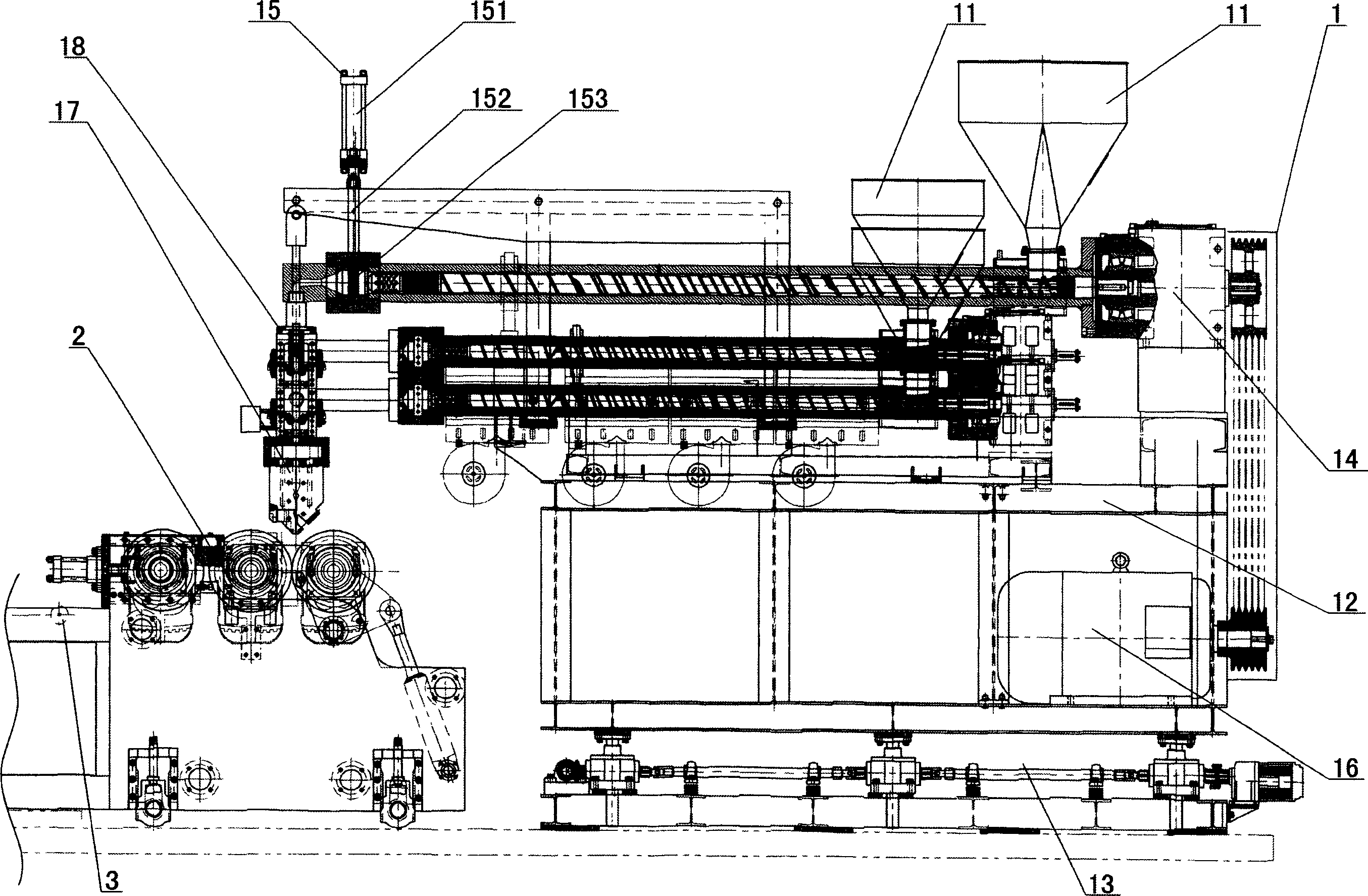

[0024] Such as Figure 1-6 As shown, the co-extrusion sheet material extrusion equipment in this preferred embodiment includes a co-extrusion device 1, and the co-extrusion device 1 includes a frame 12, a reduction box 14, a driving motor 16 and an extrusion device. In addition, five extruders 11 are included. Gear box 14, co-extrusion die head 17, drive motor 16 and five extruders 11 are all located on the frame 12, and five extruders 11 are respectively connected to drive motor 16 by gear box 14, and five extruders 11 The outlets are respectively connected to the extrusion device.

[0025] Described frame 12 is also provided with hydraulic screen changing device 15, and hydraulic screen changing device 15 comprises hydraulic cylinder 151, push rod 152 and filter screen 153, and one end of push rod 152 is connected hydraulic cylinder 151, and filter screen 153 is installed at the other end, filter screen A mesh 153 is located at the exit of the extruder 151 . In this way, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com