Automatic backflush filtering net for micro irrigation

A mesh filter, automatic backflushing technology, applied in the direction of fixed filter element filter, filtration separation, application, etc., can solve the problems of increased manufacturing cost, high manufacturing cost, complicated connection of filter equipment, etc., and achieve low manufacturing and use cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

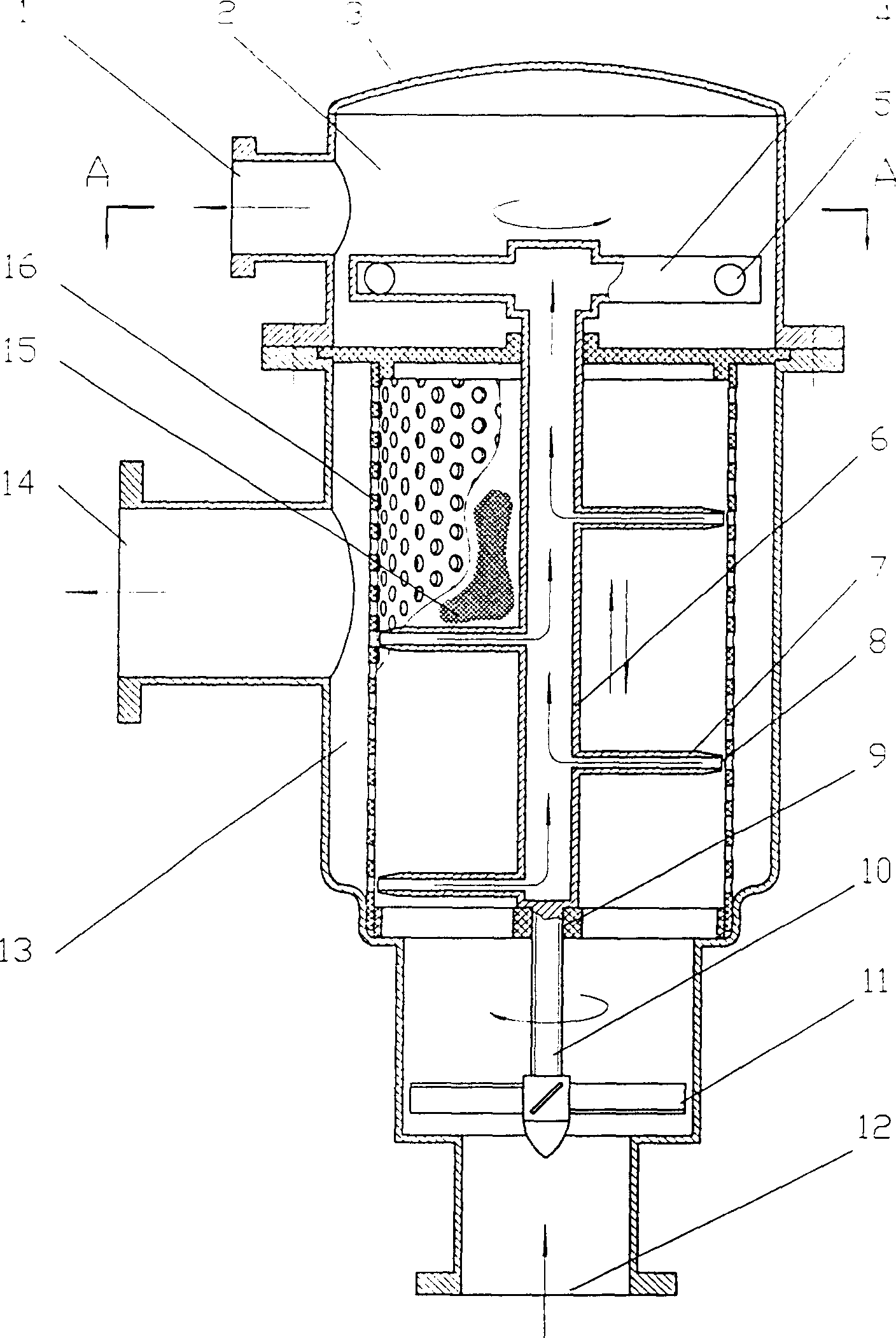

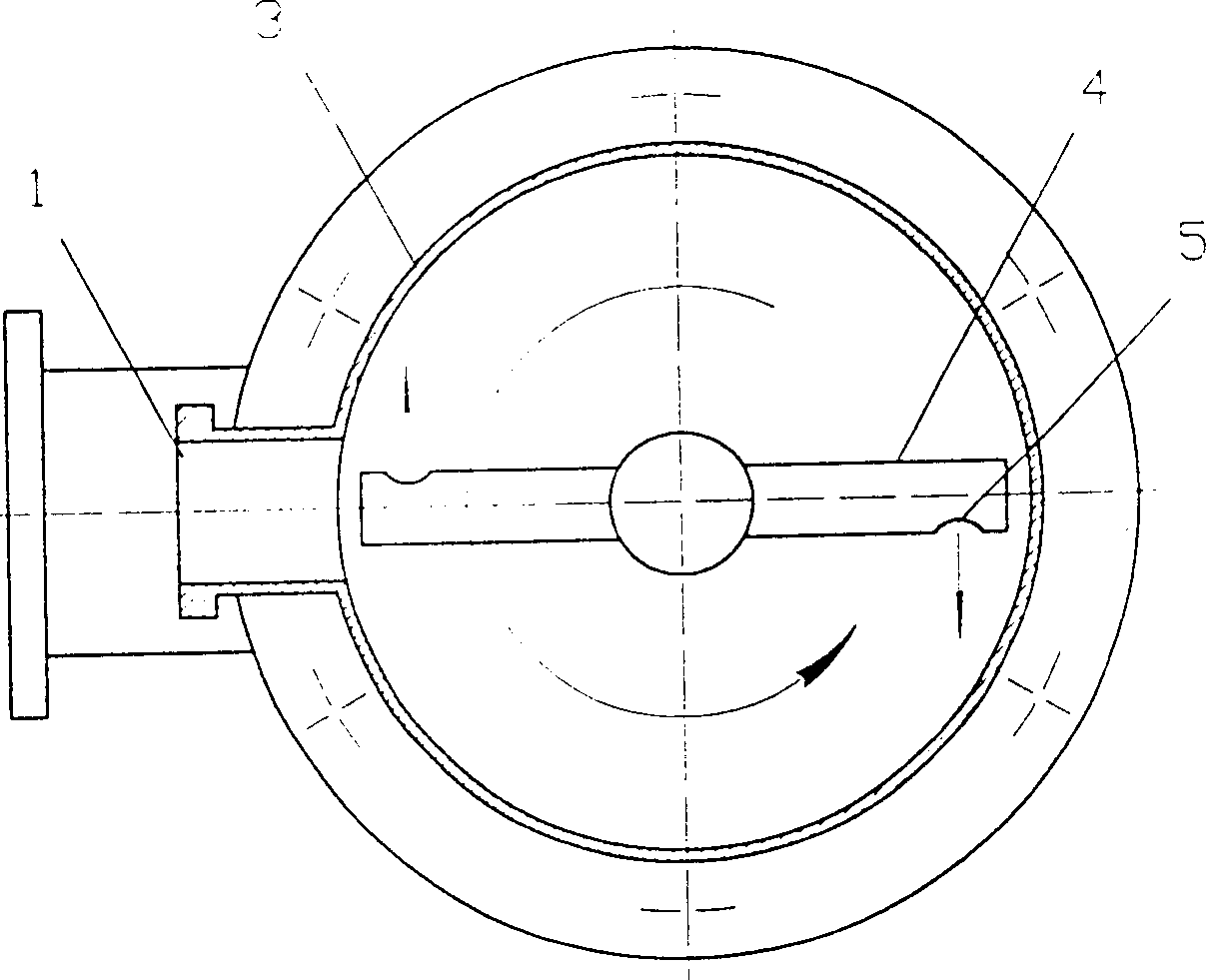

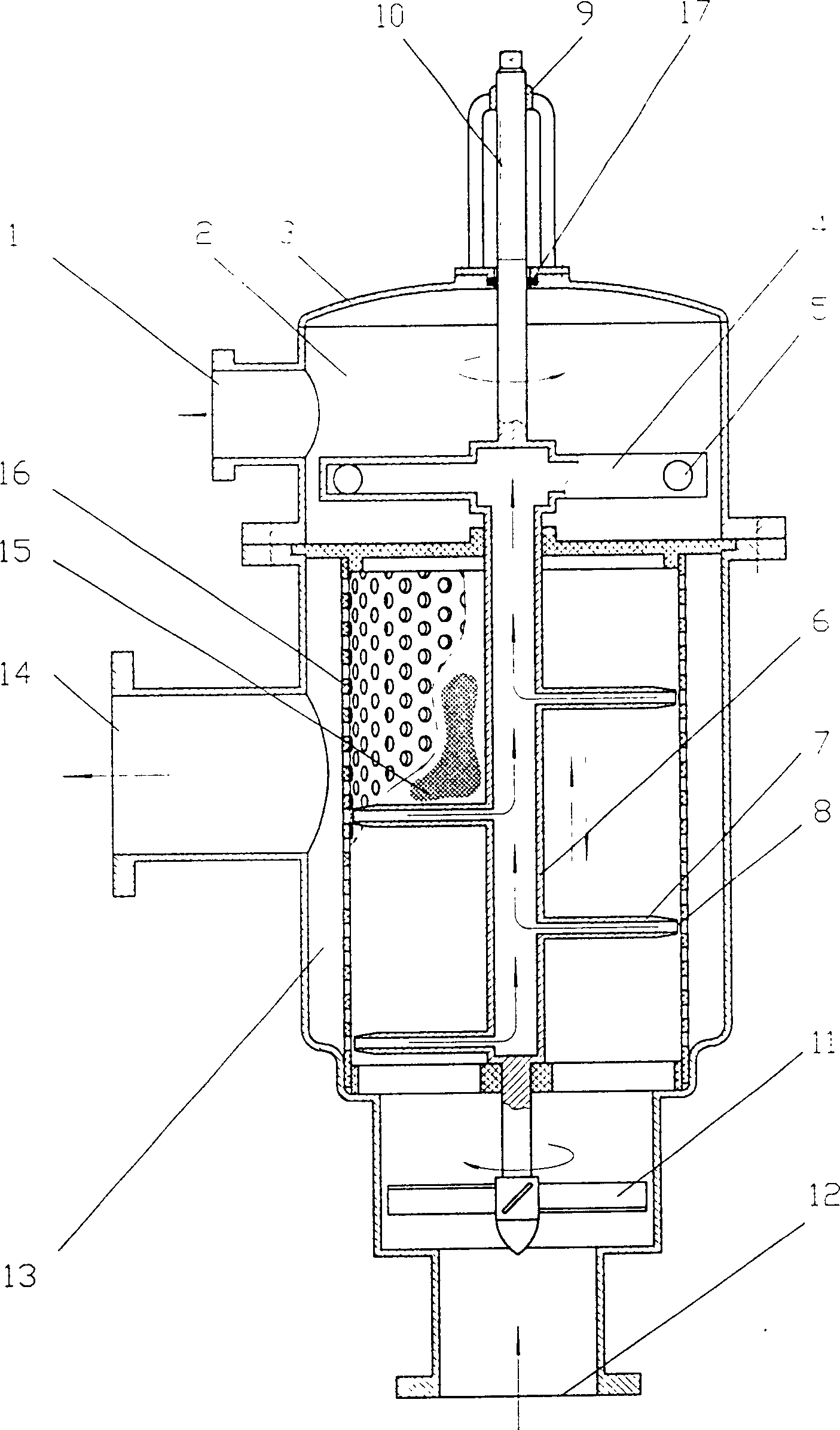

[0026] figure 1 , figure 2 Given the first embodiment of the present invention, when the filter shown in the figure is in normal use, the filter sewage outlet 1 is closed, irrigation water enters the filter chamber 13 from the water inlet 12, and the water flow pushes the rotating impeller 11 to rotate, passing through the filter net 15 is filtered and discharged from the water outlet 14; when the filter needs to be flushed, the sewage outlet 1 is opened, causing the pressure in the sewage chamber 2 to drop, and a pressure difference is formed between the filter chamber 13 and the sewage chamber 2, and this pressure difference forces water to flow through The sewage suction nozzle 11, the sewage suction pipe 7, the sewage discharge pipe 6, the spray pipe 4 and the water spray hole 5 enter the sewage discharge chamber 2 to achieve the purpose of sucking out the dirt in the filter screen. Because the spray hole 5 direction that is located at nozzle pipe 4 two ends is opposite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com