Large flow centripetal-stress sewage-treating pipeline and its production process

A technology of centripetal stress and large flow, applied in the direction of manufacturing tools, pipes, rigid pipes, etc., can solve the problems of high engineering cost and waste of huge funds, and achieve the effect of reducing engineering volume, preventing infringement and saving hydraulic resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be discussed in detail below in conjunction with embodiment:

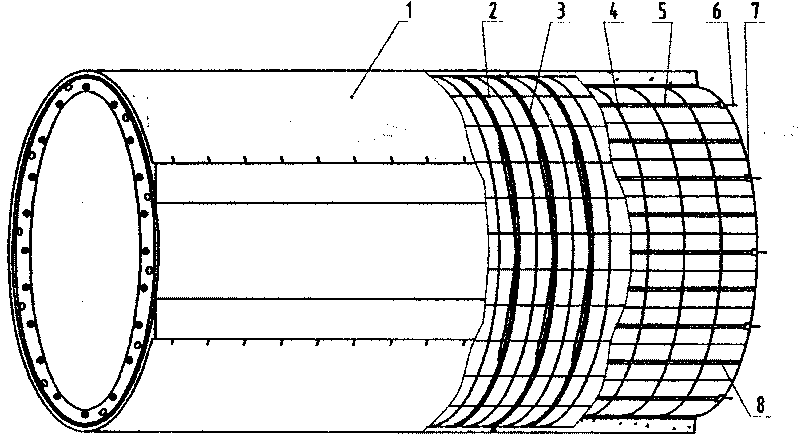

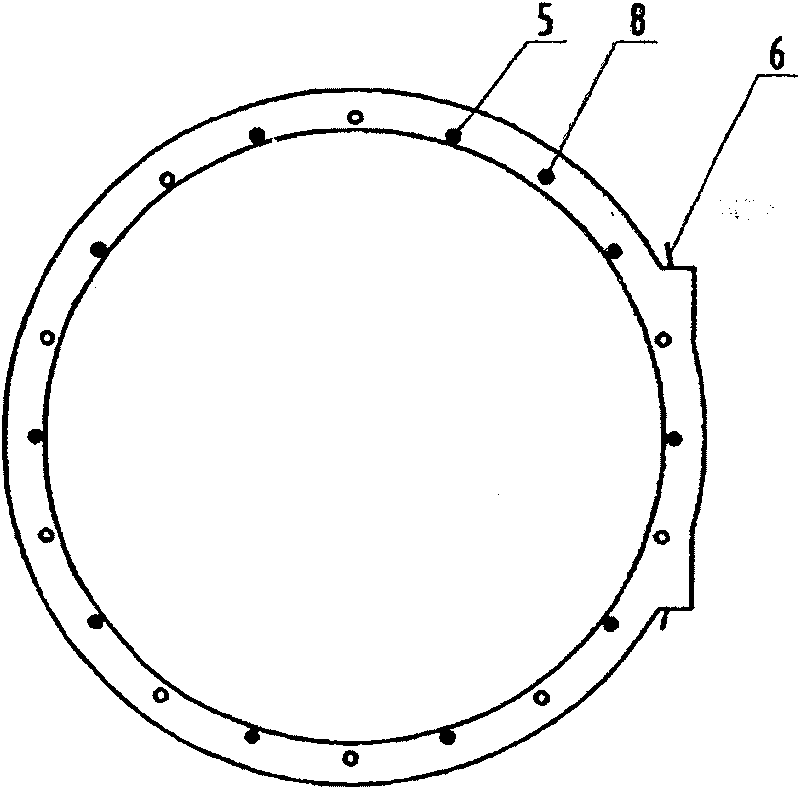

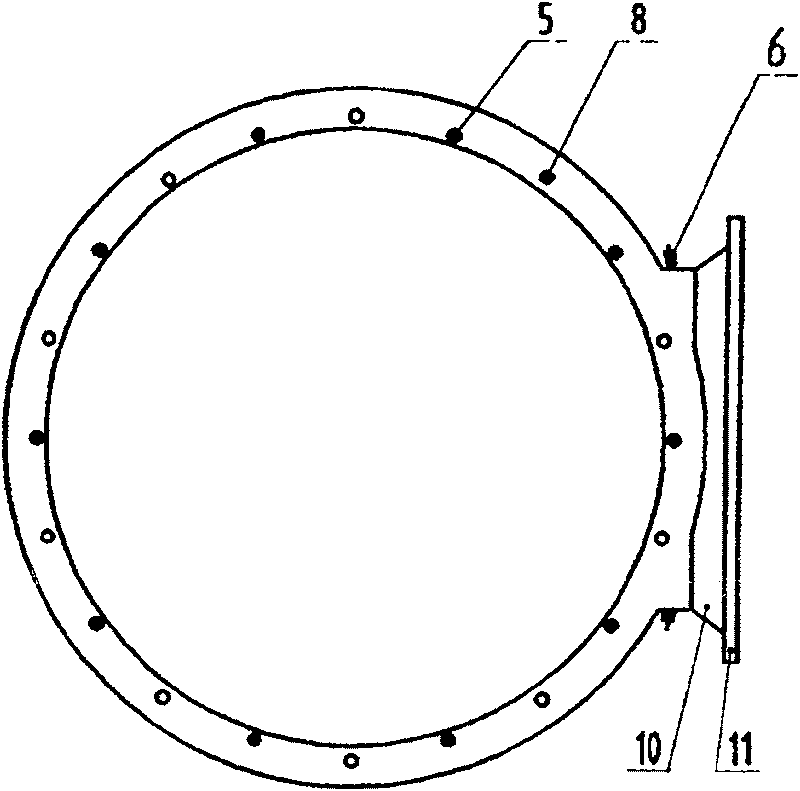

[0049] as attached figure 1 As shown, the present invention includes a concrete pipe body 1 and an outer skeleton 2 and an inner skeleton 4 that are arranged in the pipe body 1 and are composed of longitudinal ribs and ring ribs. The inner side or outer side of the outer skeleton 2 is fixed with a hoop The outer side of the tube 3 and the inner skeleton 4 is fixed with a longitudinal bobbin 5 , and a reserved hole 8 is arranged between the outer skeleton 2 and the inner skeleton 4 .

[0050] as attached figure 1 , 2 As shown, the present invention is provided with a hoop bobbin 3 on the inside or outside of the inner and outer skeletons 2 of the tube body 1, and there is a hoop tube body in the hoop bobbin 3, and a ring of the hoop body is formed on the outside of the tube body by tensioning correspondingly. To the prestressed steel strand 7, an anchorage device 9 for anchoring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com