Illumination device

A lighting device and lighting field technology, applied in the field of marking devices, can solve the problems of expensive lighting devices, and achieve the effect of reducing installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

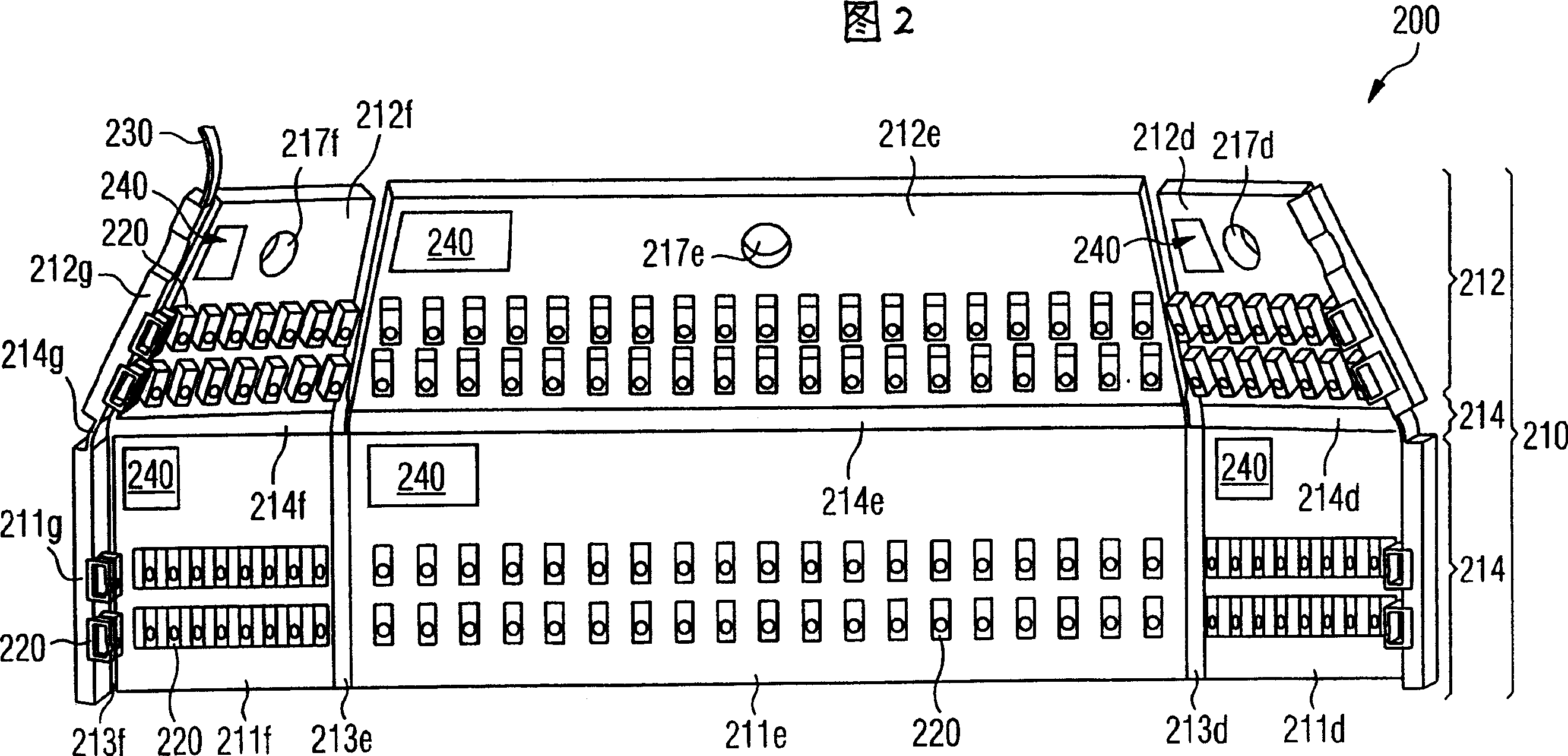

[0027] It should be noted here that, in the figures, the numbering of corresponding components differs only in the first digit.

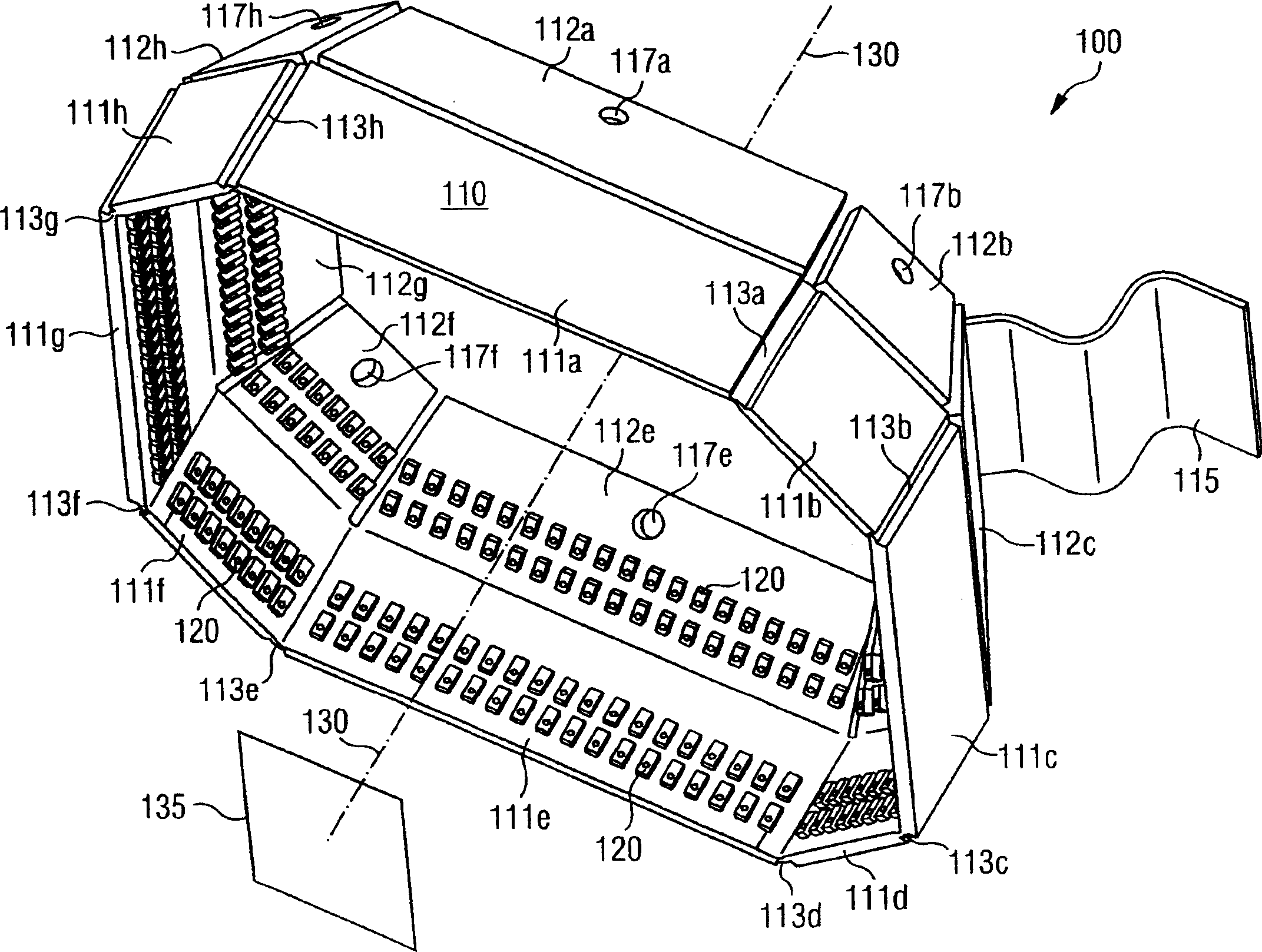

[0028] figure 1 A lighting device 100 is shown, which has a circuit carrier 110 on which a plurality of different light emitting diodes 120 are mounted. The circuit carrier 110 is octagonal, and the rigid regions 111a, 111b, 111c, 111d, 111e, 111f, 111g, 111h are connected by seven flexible intermediate regions 113a, 113b, 113c, 113d, 113e, 113f, 113g . Every two adjacent rigid regions 111 form an angle with each other, and the right side of the rigid region 111h is at least almost touching the left side of the rigid region 111a. In this way, the rigid region 111 a of the circuit carrier 110 forms an almost closed octagon symmetrical about the optical axis 130 . On the optical axis 130 there is an illumination field 135 , which is illuminated by the illumination device 100 with a sufficiently uniform light intensity from different illumination an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com