Cruciform spring element

A technology of components and cross springs, which is applied in the field of cross-shaped or cross spring components, can solve problems such as changes in spring stiffness or elastic coefficient, and achieve the effect of small hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

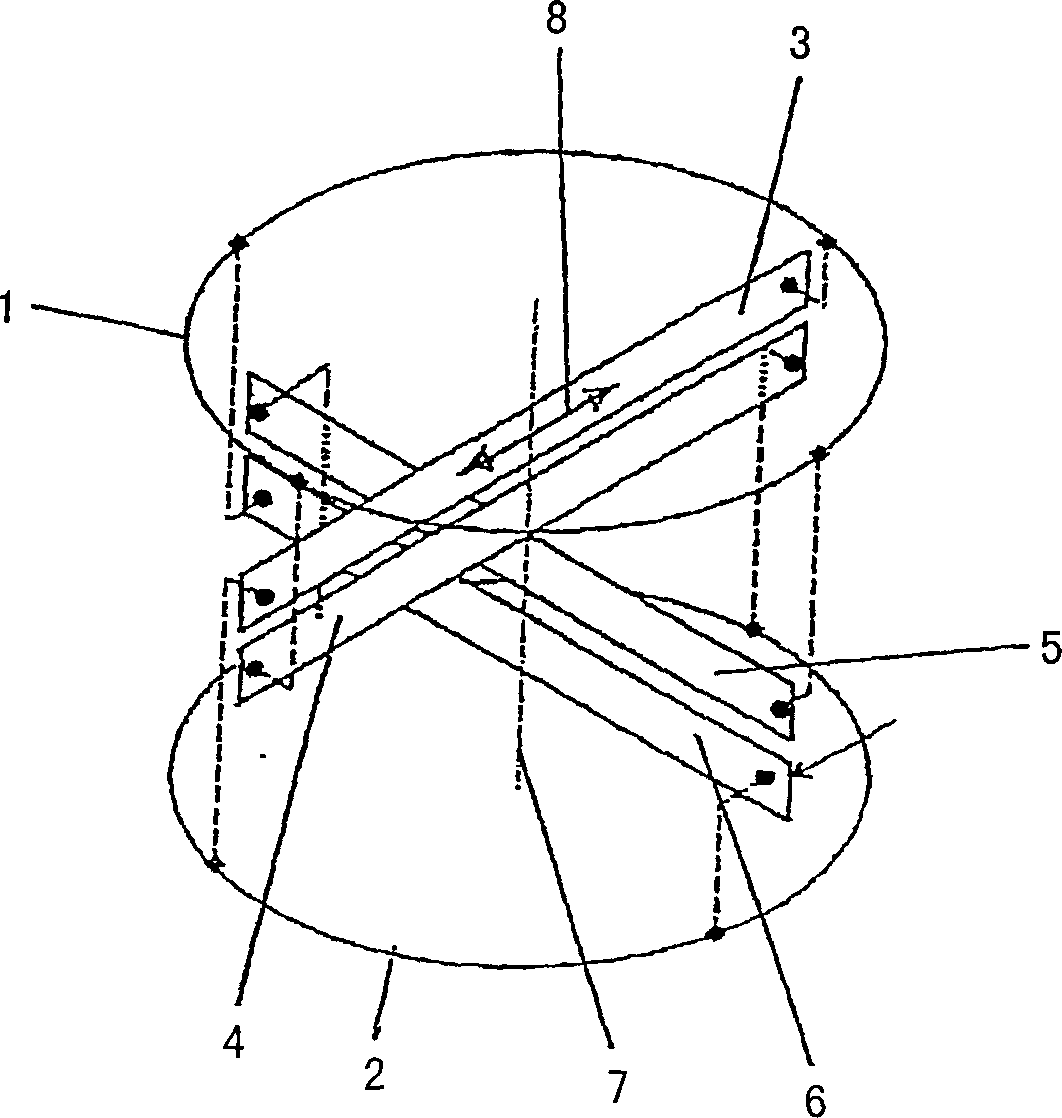

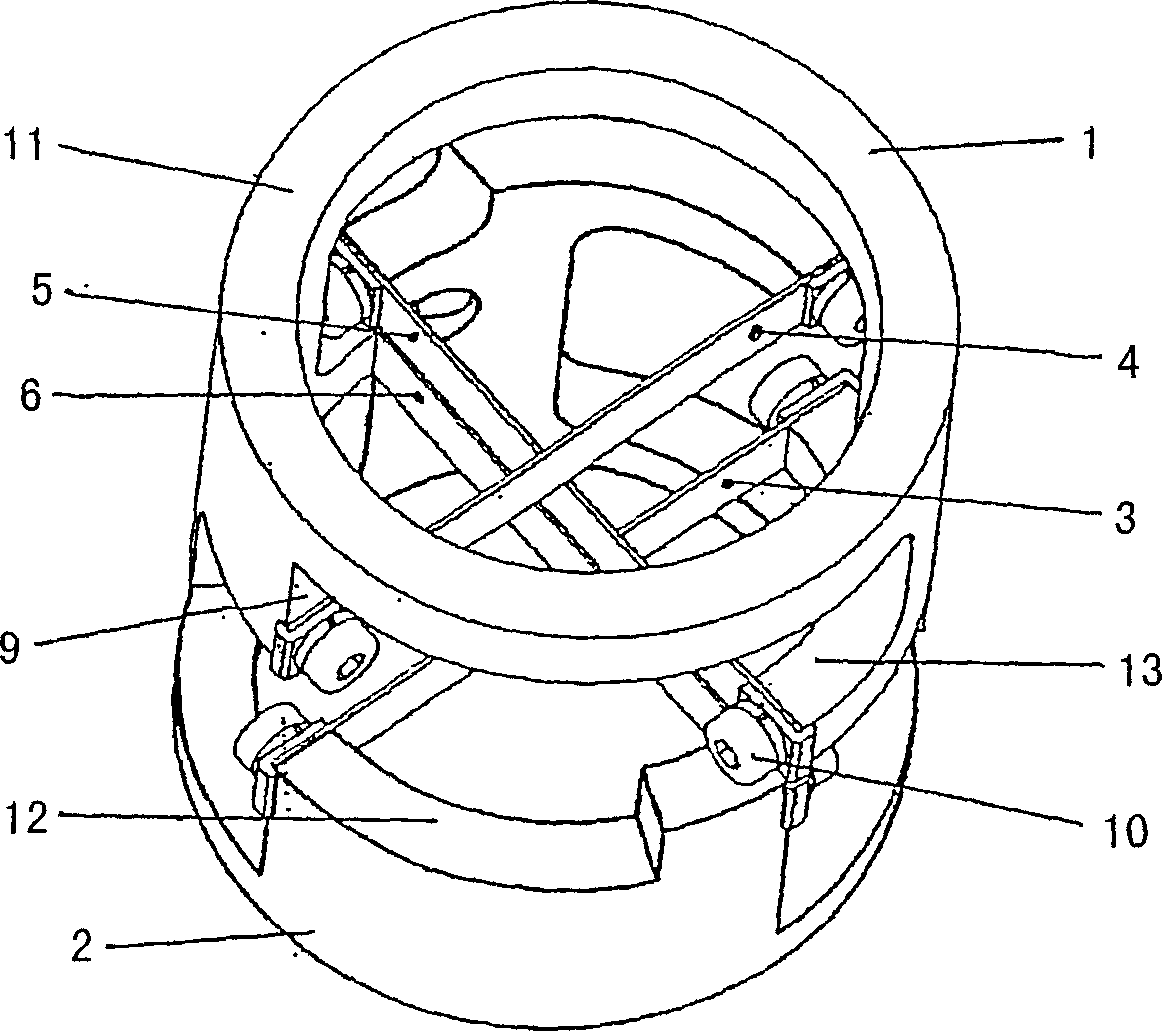

[0016] exist figure 1 In , a cross-spring element for a mass flow measurement device according to the Coriolis principle is schematically shown. The cross spring element consists of 4 pairs of cross leaf springs 3 , 4 , 5 , 6 which are fastened to two annular bearing elements 1 , 2 .

[0017] This cross-spring element is provided in particular to connect the drive shaft of the impeller, which is mounted in a bushing not shown, to the pivotally or pendulously mounted force-measuring device. Such a device is disclosed in patent application number 10253078.5-52 filed with the German Patent and Trademark Office on November 13, 2002. In this respect, the force-measuring device is supported by an intermediate transmission on the drive motor. To this end, the bearing elements 1 , 2 are each connected to a toothed gear which rotates in mesh with two intermediate gears of similar type and which are synchronously driven by a drive motor. In this respect, one of the intermediate gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com