Electrophoretic display unit

An electrophoretic display and electrophoresis technology, which is applied to static indicators, instruments, etc., can solve the problems of inflexible driving of electrophoretic display units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

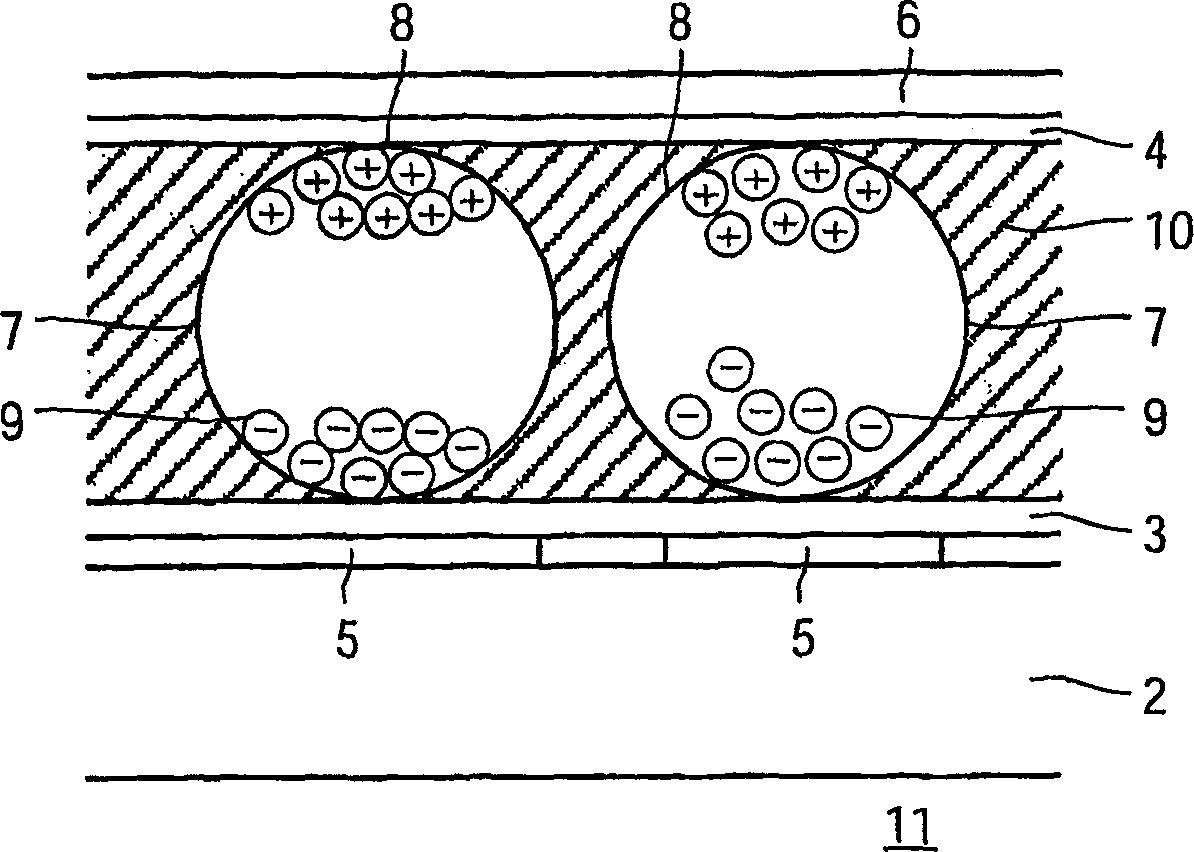

[0034] figure 1 The pixel 11 of the electrophoretic display unit shown (in cross section) comprises a base substrate 2, an electrophoretic film (laminated on the base substrate 2) with electronic ink present on two transparent substrates such as polyethylene Between the substrates 3 and 4 , one substrate 3 is provided with a transparent pixel electrode 5 , and the other substrate 4 is provided with a transparent common electrode 6 . Electronic ink comprises a plurality of microcapsules 7 approximately 10 to 50 microns in diameter. Each microcapsule 7 comprises positively charged white particles 8 and negatively charged black particles 9 suspended in a liquid 10 . When a positive electric field is applied to the pixel electrode 5, the white particles 8 move to the side of the microcapsule 7 pointing to the common electrode 6, and the pixel can be seen by the viewer. At the same time, the black particles 9 move to the opposite side of the microcapsules 7, where they are hidden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com