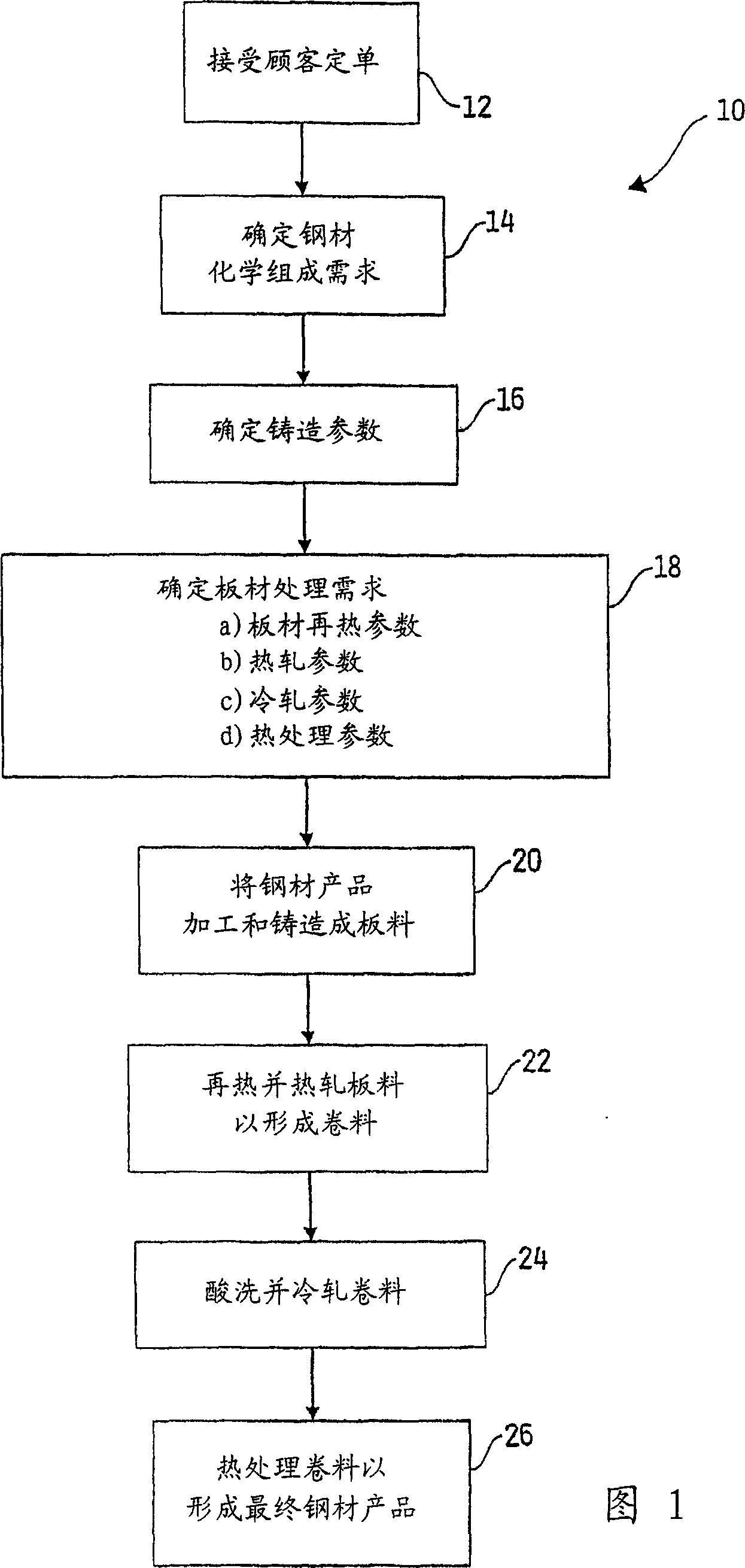

Method for custom-making steel strip

A technology of steel strip and order, applied in the direction of instruments, manufacturing tools, casting workshops, etc., can solve the problems of long cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] For the purposes of facilitating an understanding of the principles of the invention, reference will be made to the preferred embodiment shown in the drawings and specific language will be used to describe the same. Nevertheless, it should be understood that no limitation of the scope of the invention is intended thereto, and that changes and further modifications in the illustrated embodiments, as well as further applications of the principles of the invention shown herein, will be apparent to those skilled in the art. considered to occur normally.

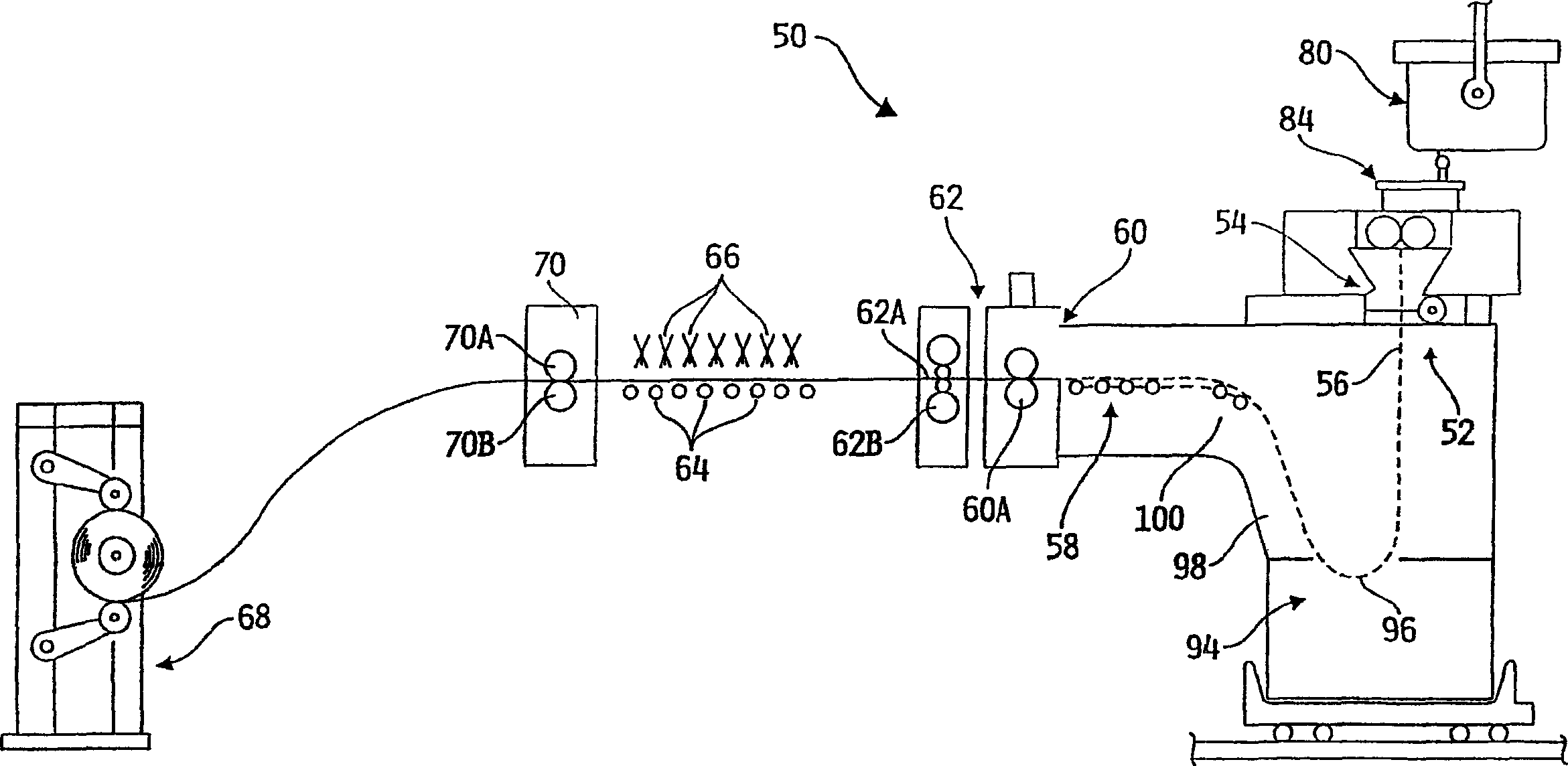

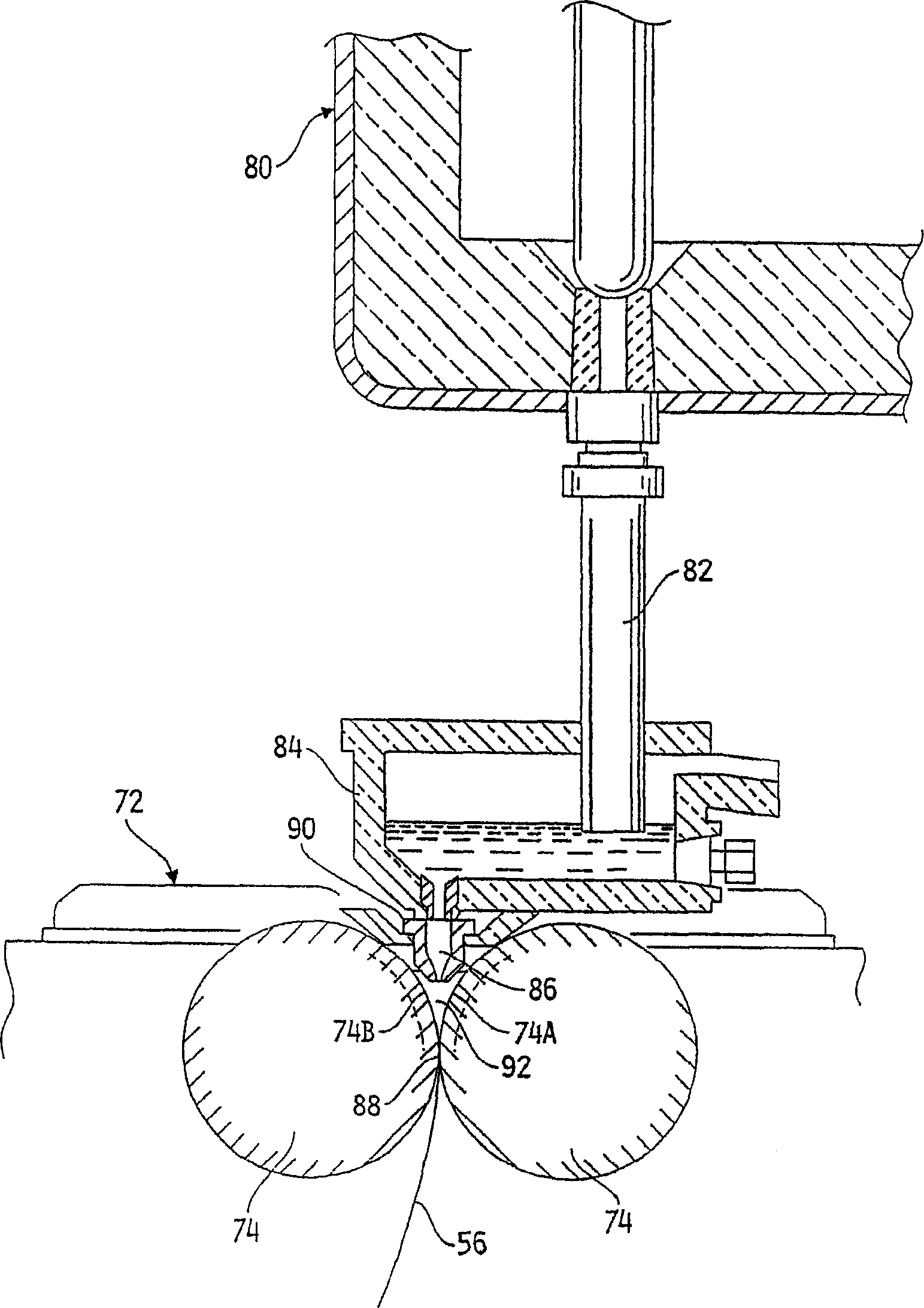

[0025] The invention is based on the production of steel strip in a continuous strip caster. The applicant has carried out extensive research and development work in the field of continuous strip casting machines in the form of twin roll casting machines for casting steel strip. Broadly speaking, continuous casting of steel strip in a twin-roll caster involves introducing molten steel between a pair of counter-rotating ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com