Extrusion type puffing device

An extruding device and extruding technology, which is applied in the field of feed machinery and food, can solve the problems that it is difficult to ensure the degree of product expansion, the output of extruded products produced by extrusion equipment decreases, and the degree of maturation of materials cannot be well guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

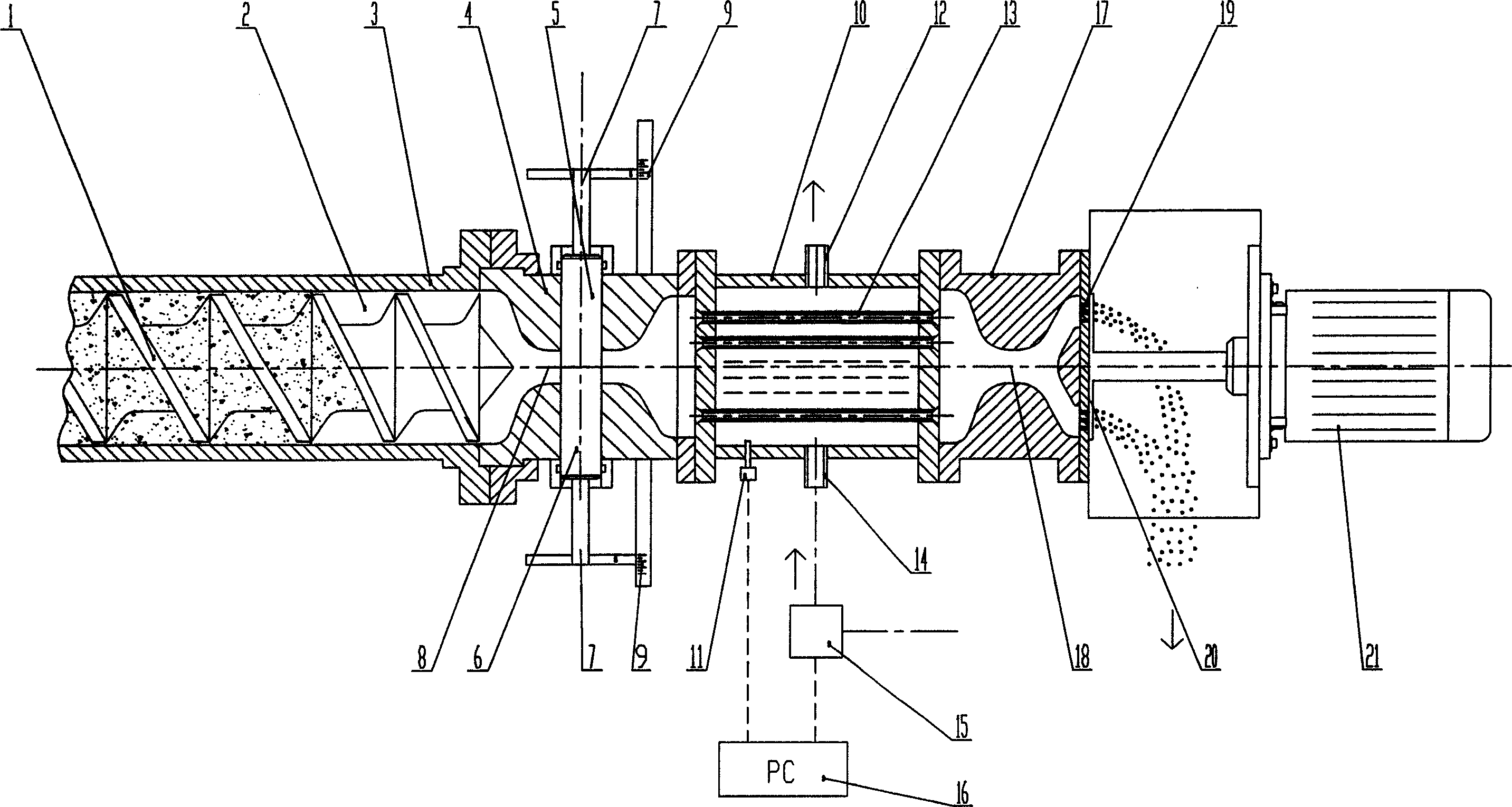

[0011] like figure 1 , is an extruding type puffing device, comprising an extruding cavity 3, an extruding screw 1 matching the extruding cavity 2 is arranged in the extruding cavity 3, and the discharge end of the extruding screw 1 is provided with an extruding The steady-flow extruder 4 connected to the cavity 3 is provided with an extrusion hole 8 coaxial with the extrusion screw 1, and the steady-flow extruder 4 is provided with a vertical through extrusion In the cavity of the hole 8, an upper piston 5 and a lower piston 6 are symmetrically arranged in the cavity, and the upper piston 5 and the lower piston 6 are respectively arranged on the stroke adjustment rod 7, and an indicator scale 9 is provided on the side of the stroke adjustment rod 7 for indicating adjustment The size of the opening of the extrusion hole 8 is controlled by the displacement of the upper piston 5 and the lower piston 6. During the production process, the adjustment can be realized and the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com