Extra long aerated expansion supporting rod for outer space

A technology of inflatable deployment and support rods, which is applied to aerospace equipment, aerospace aircraft, aircraft and other directions, can solve the problems of low folding efficiency, high weight, inability to build large-scale space structures, etc., and achieves simple structure, high folding efficiency, Easy-to-control effects during unfolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

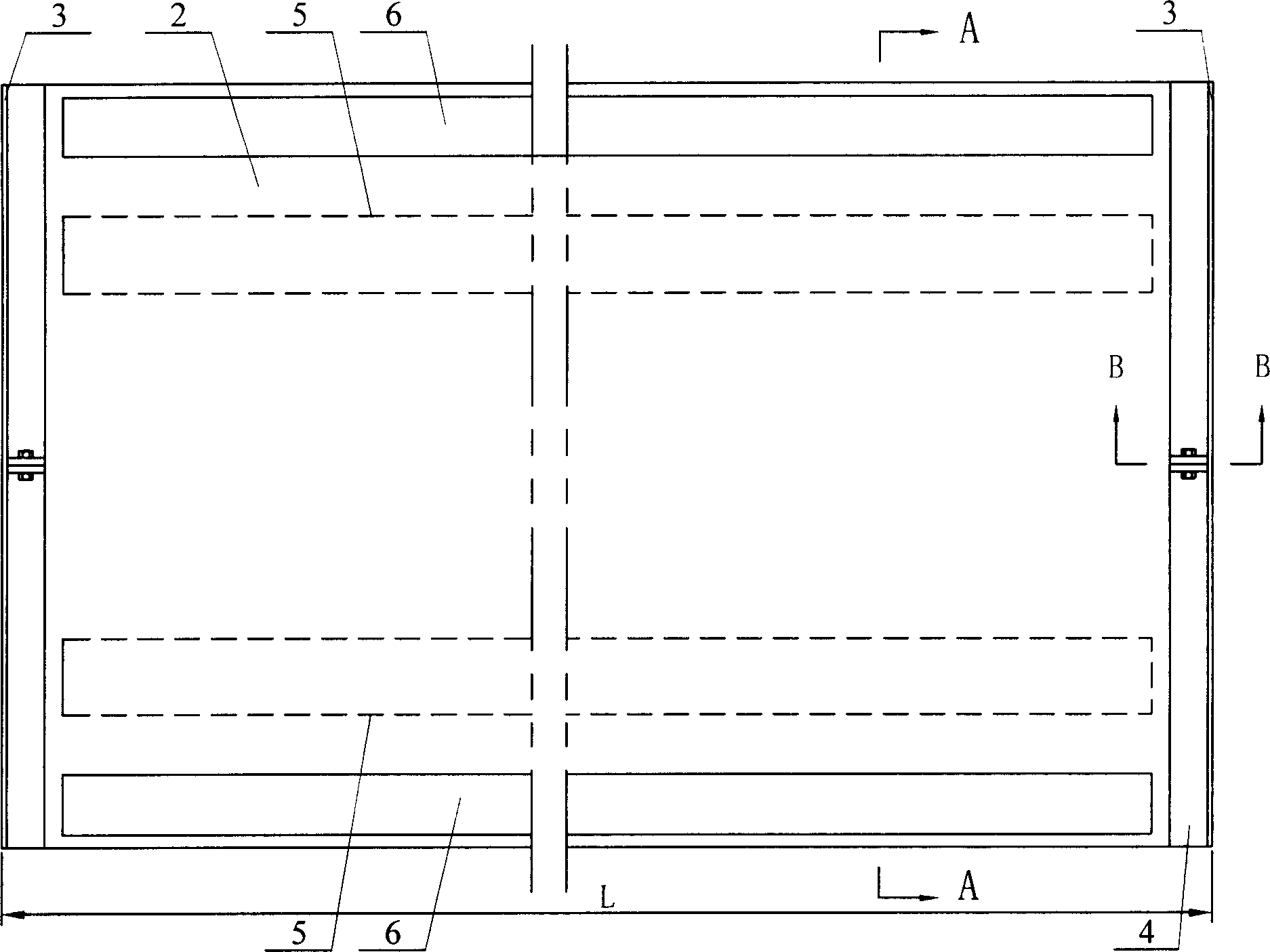

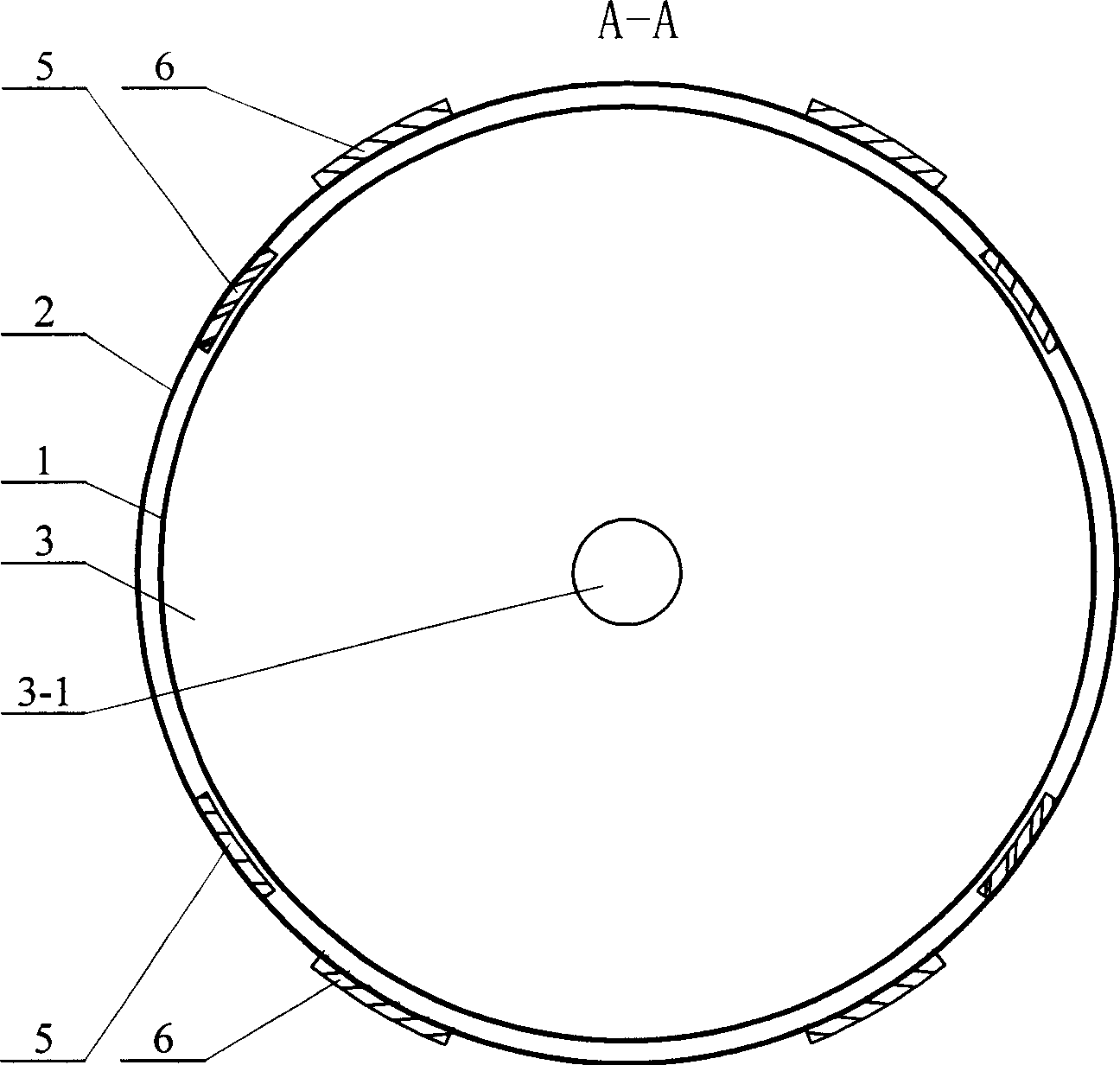

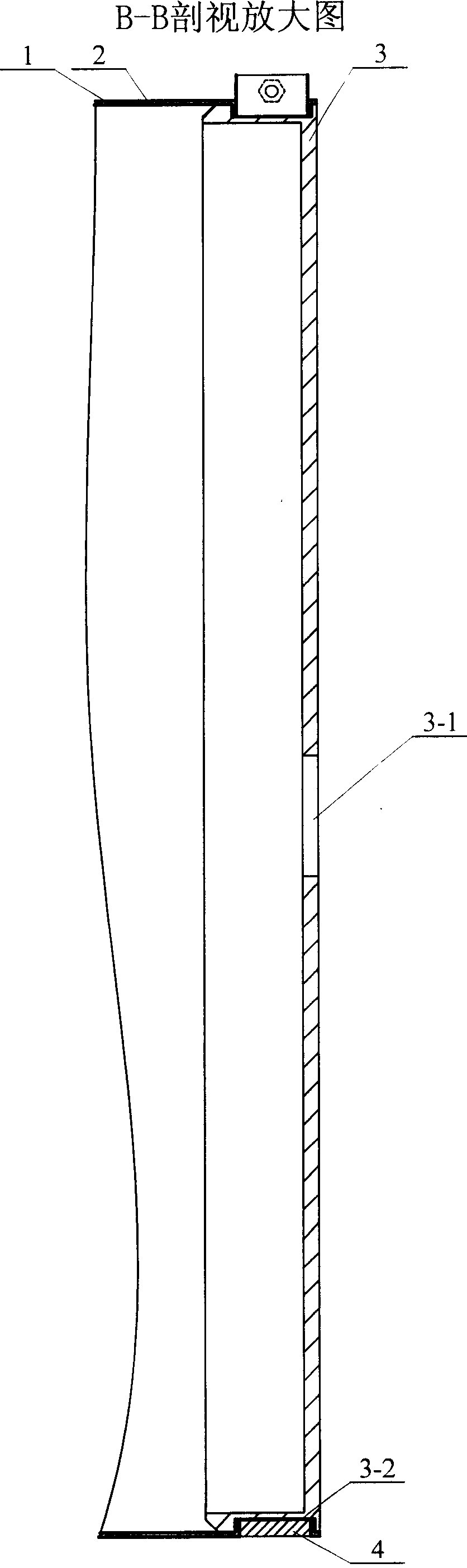

[0007] Specific implementation one: (see Figure 1-Figure 4 ) This embodiment is composed of an inner layer tube 1, an outer layer tube 2 and two cylindrical end caps 3, the inner layer tube 1 is placed in the outer layer tube 2, and each end cap 3 has an inflatable hole in the center 3-1, the two end caps 3 are sealed and connected with the two ends of the inner layer tube 1 and the outer layer tube 2 respectively; the length L of the support rod is 10-100m; the inner layer tube 1 and the outer layer tube 2 are made of film materials .

specific Embodiment approach 2

[0008] Specific implementation two: (see Figure 1-Figure 4 ) The difference between this embodiment and the first embodiment is that the length L of the support rod is 10-39 m. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation three: (see Figure 1-Figure 4 ) The difference between this embodiment and the first embodiment is that the length L of the support rod is 10m. Other components and connection relationships are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com