Backlight module reflector plate

A technology of backlight module and reflective sheet, applied in the field of reflective sheet, can solve the problems of increasing assembly steps, increasing assembly time, reducing the production quantity of backlight modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable the examiner to have a further understanding and understanding of the structural features and the achieved effects of the present invention, I would like to provide preferred embodiments and detailed descriptions, as follows:

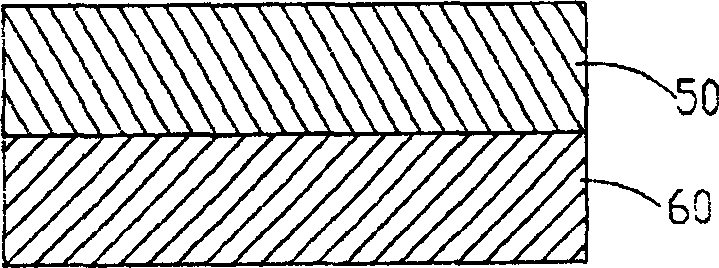

[0042] see figure 2 , which is a structural diagram of a preferred embodiment of the present invention; as shown in the figure, the reflective sheet of the backlight module of the present invention includes a reflective layer 50 and a conductive layer 60 , and the conductive layer 60 is disposed on one side of the reflective layer 50 . In this way, when the reflection sheet of the backlight module of the present invention is assembled in the backlight module, the conductive layer 60 is oriented to the outside of the backlight module, and the conductive layer 60 is connected to the ground wire of the backlight module to prevent electromagnetic interference to the components of the backlight module. Normal operation, and through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com