Apparatus for continuous extracting and sterilizing solid materials under high and ultrahigh pressure

A technology of solid materials and sterilization equipment, applied in the direction of solid solvent extraction, the method of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc., can solve the problems of not obtaining very significant effects, catastrophic explosion accidents, workers Solve problems such as high labor intensity, achieve the effect of reasonable structure, reduce production cost, and improve safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Two embodiments are given in conjunction with the accompanying drawings.

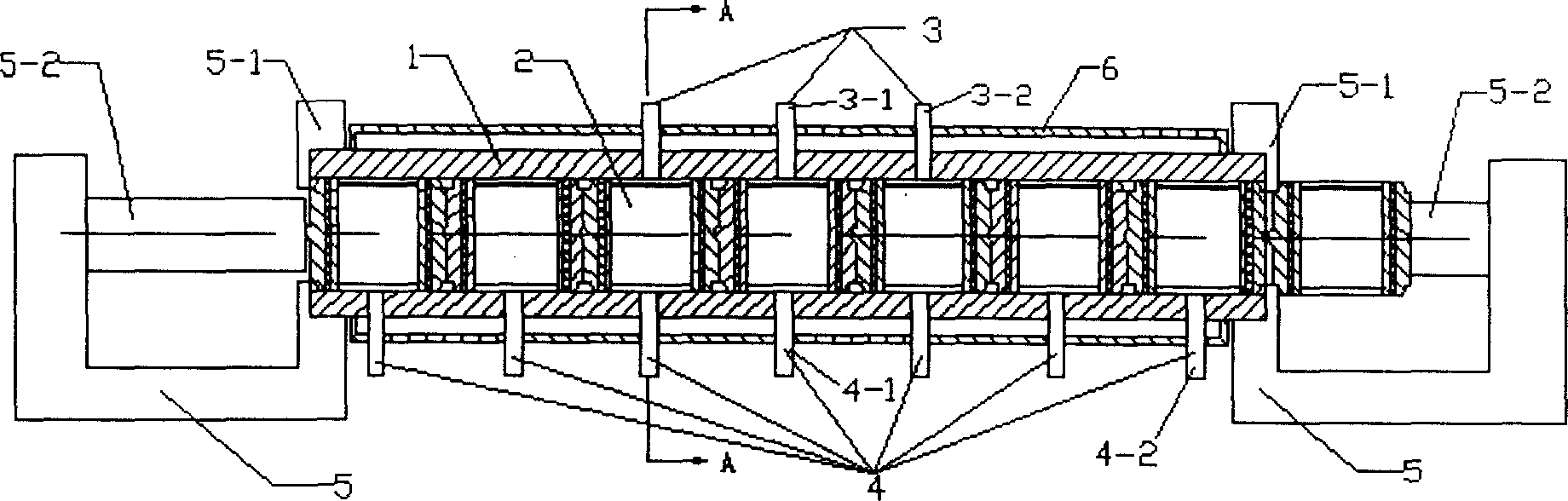

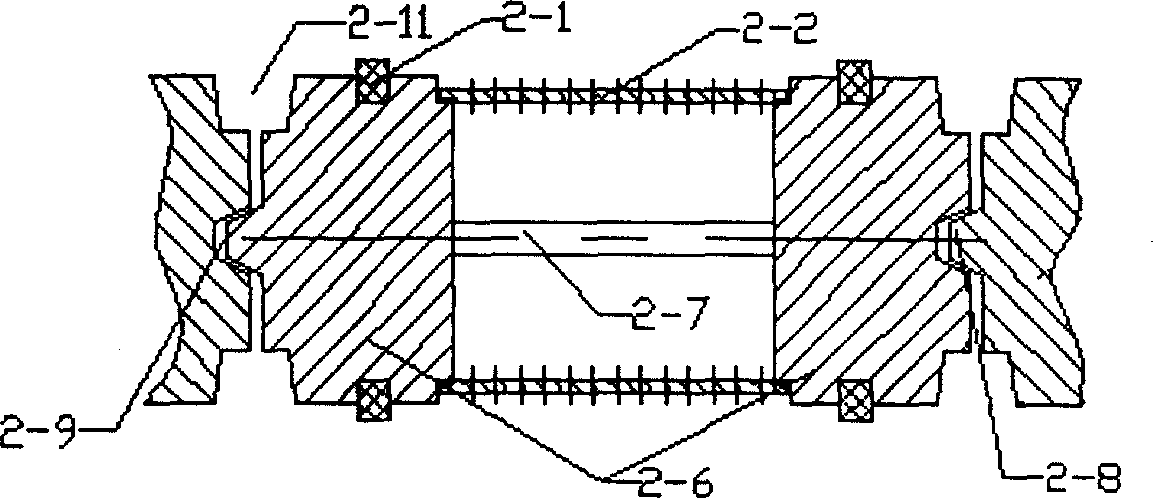

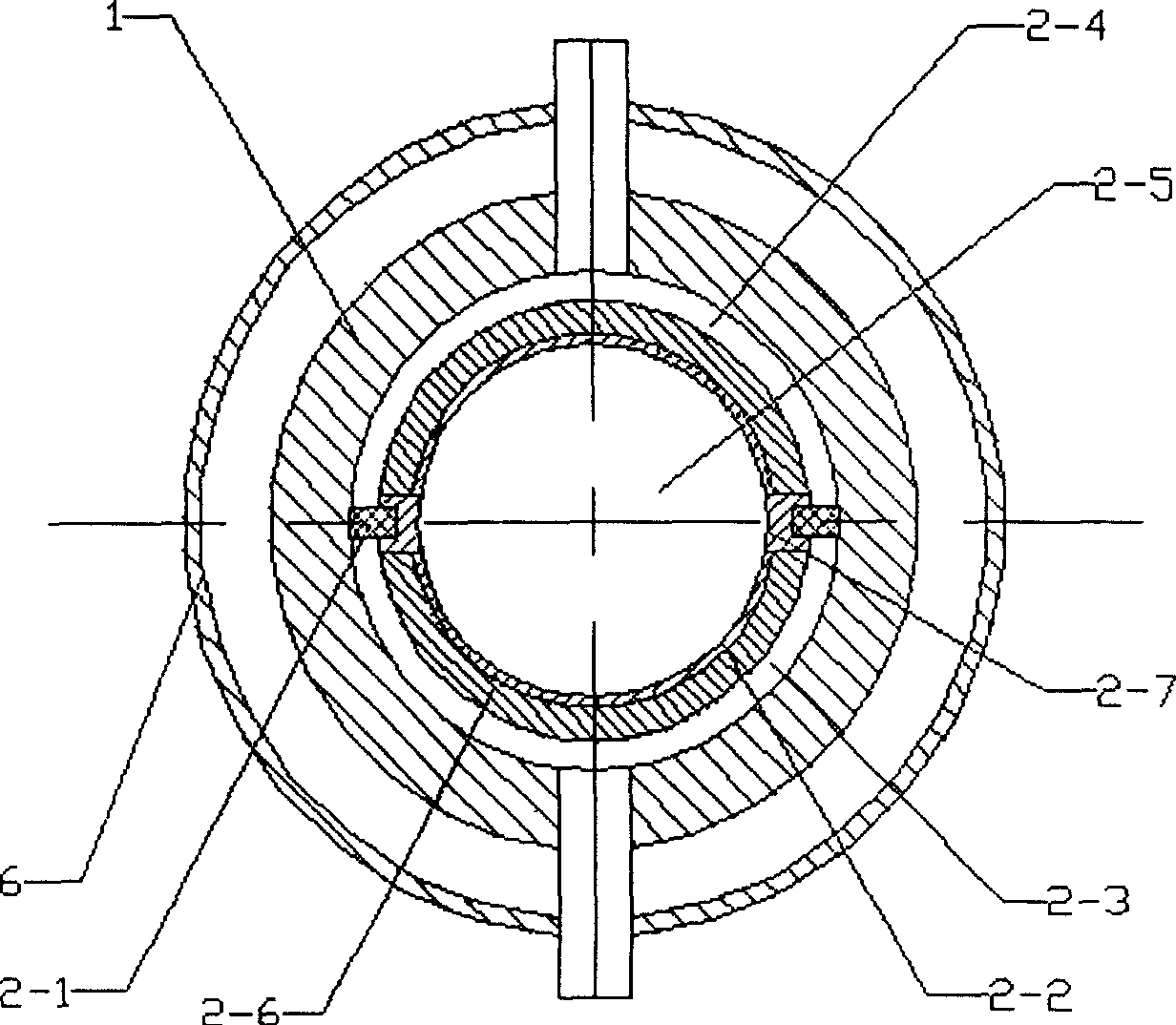

[0023] 1. High-pressure and ultra-high pressure continuous extraction and sterilization device of hydraulic piston type silo operation drive mechanism: such as figure 1 , figure 2 and image 3 As shown, the pressure-bearing cylinder 1 is made of stainless steel thick-walled pipe or forging; -6 is connected as a whole by welding, and the outer circle of the end cover 2-6 and the outer surface of the longitudinal connecting beam 2-7 are on the same cylindrical surface through machining, and then the outer edge of the outer end surface of the end cover 2-6 is opened to form a locking groove 2-11; The cylindrical surface of the end cover 2-6 is formed with a circumferential sealing groove, and the outer surface of the longitudinal connecting beam is formed with a longitudinal sealing groove. The circumferential sealing groove and the longitudinal sealing groove are connected to each other. Tetraf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap