Gas fuel catalytic combustor

A catalytic burner, gas fuel technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of small application range of catalytic combustion stoves and high NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

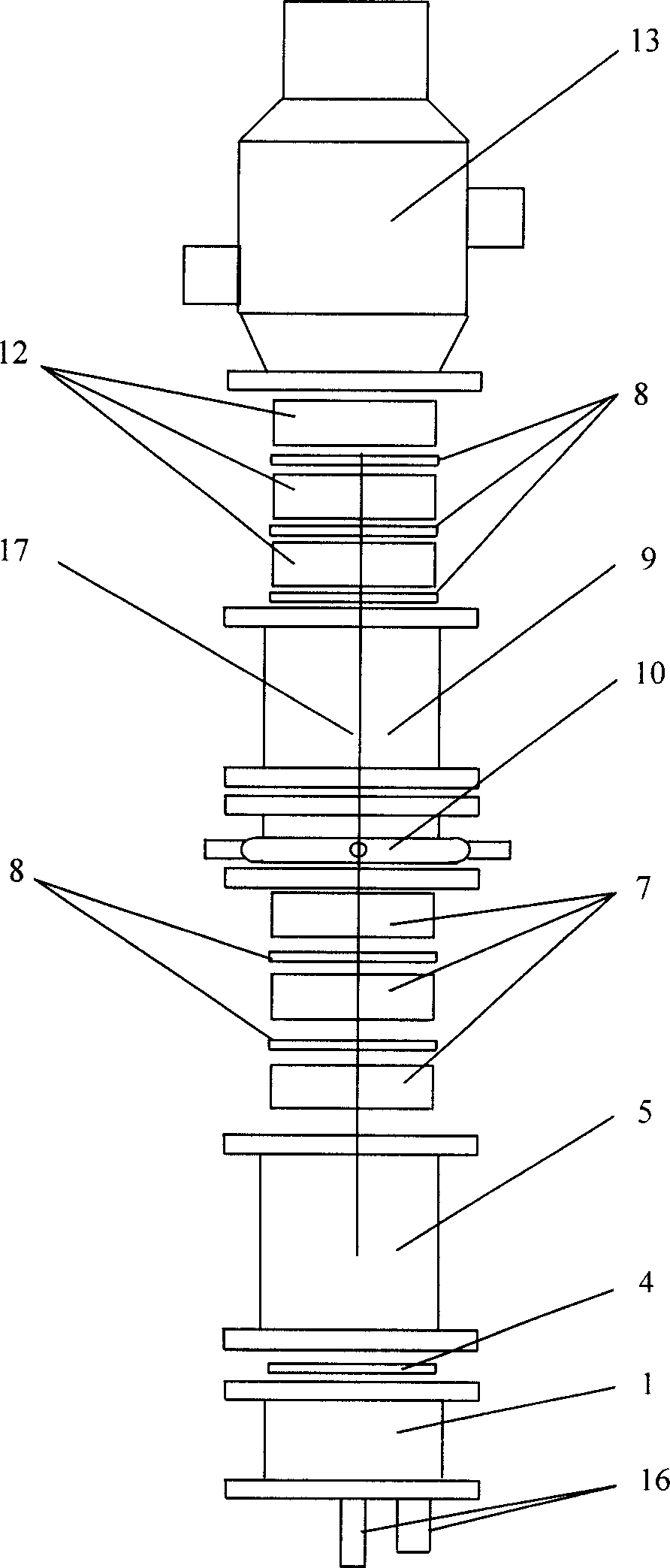

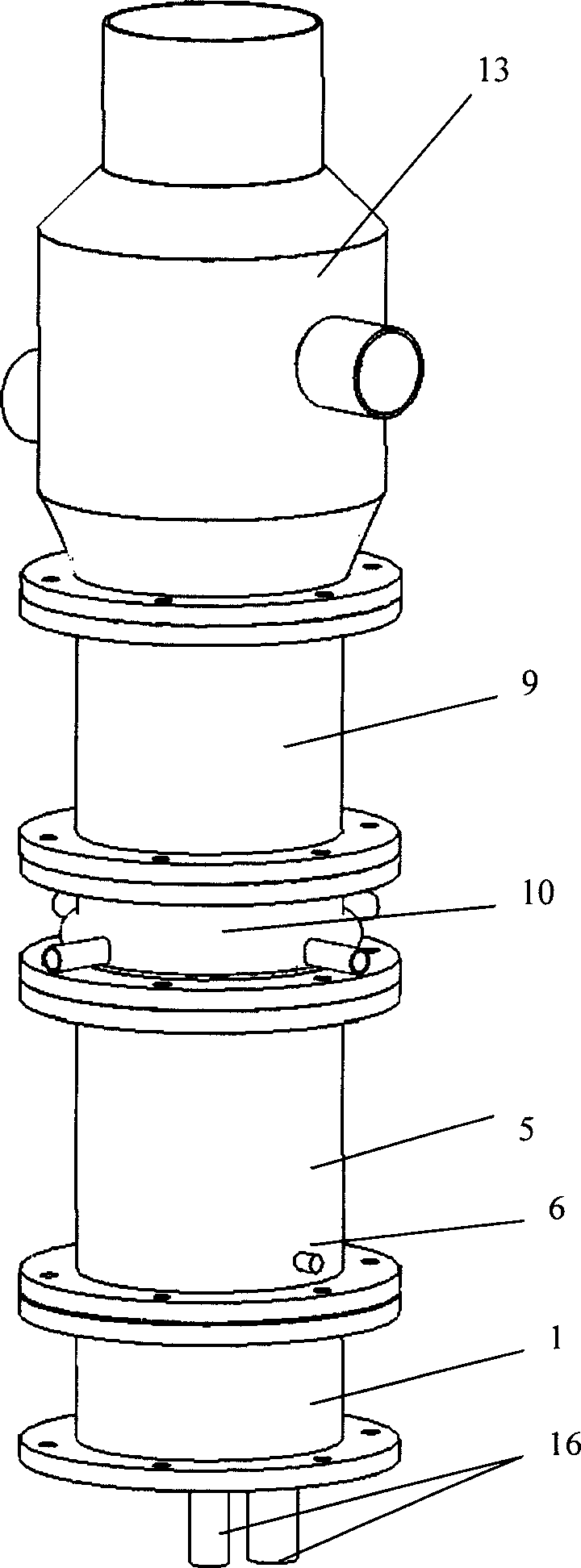

[0020] refer to figure 1 and figure 2 , The catalytic combustion furnace includes: gas premixing chamber 1, first catalytic combustion chamber 5, second catalytic combustion chamber 9, secondary gas or air mixing chamber 10, shell and tube heat exchanger 13 five main parts.

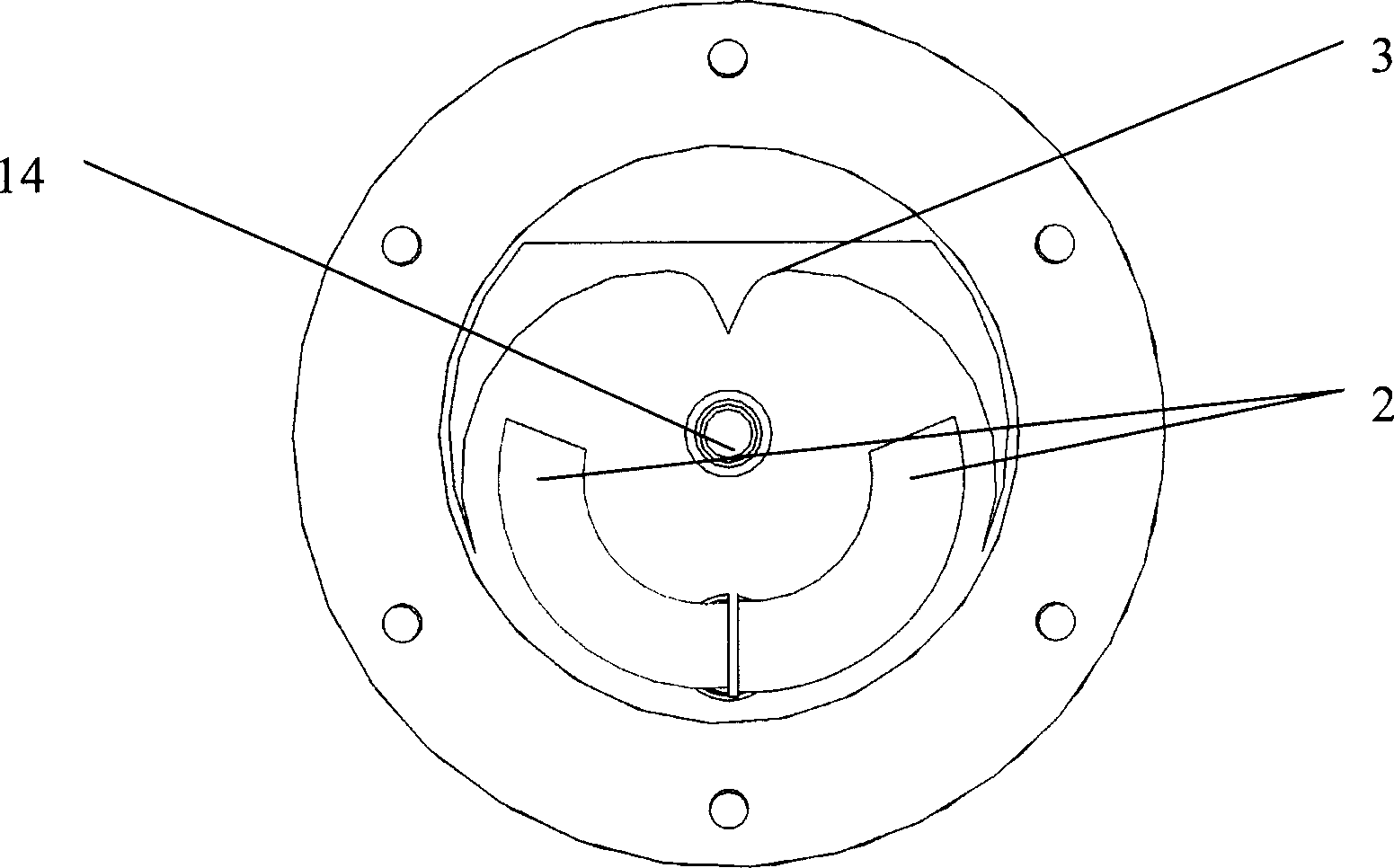

[0021] The air guide pipe 2 in the premixing chamber 1 is composed of two 1 / 4 arc circular tubes, the cyclone guide surface 3 is composed of four 1 / 4 arc cylindrical surfaces, and the center of the cyclone guide surface is The radius of the two 1 / 4 arcs is 1 / 5 of the radius of the two outer 1 / 4 arcs. Catalytic combustion chamber is made up of two catalytic combustion chambers of the first catalytic combustion chamber 5 and the second catalytic combustion chamber 9, the first catalytic combustion chamber 5 bottom is provided with igniter 6, and 2 layers of catalytic combus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com