Collecting device of spinning machine

A spinning machine and collection technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve problems such as failure to combine fibers, clogging, and affecting collection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

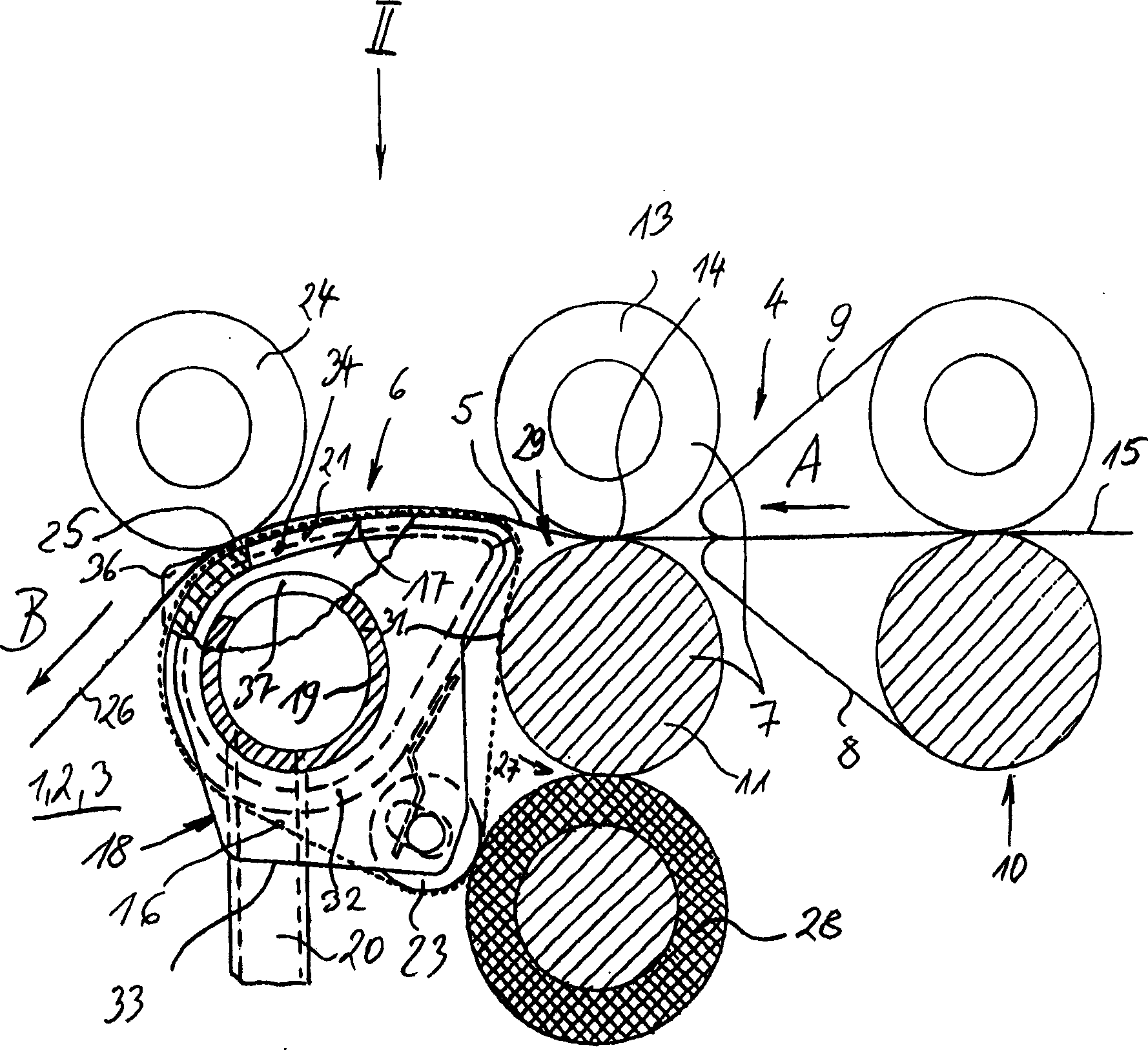

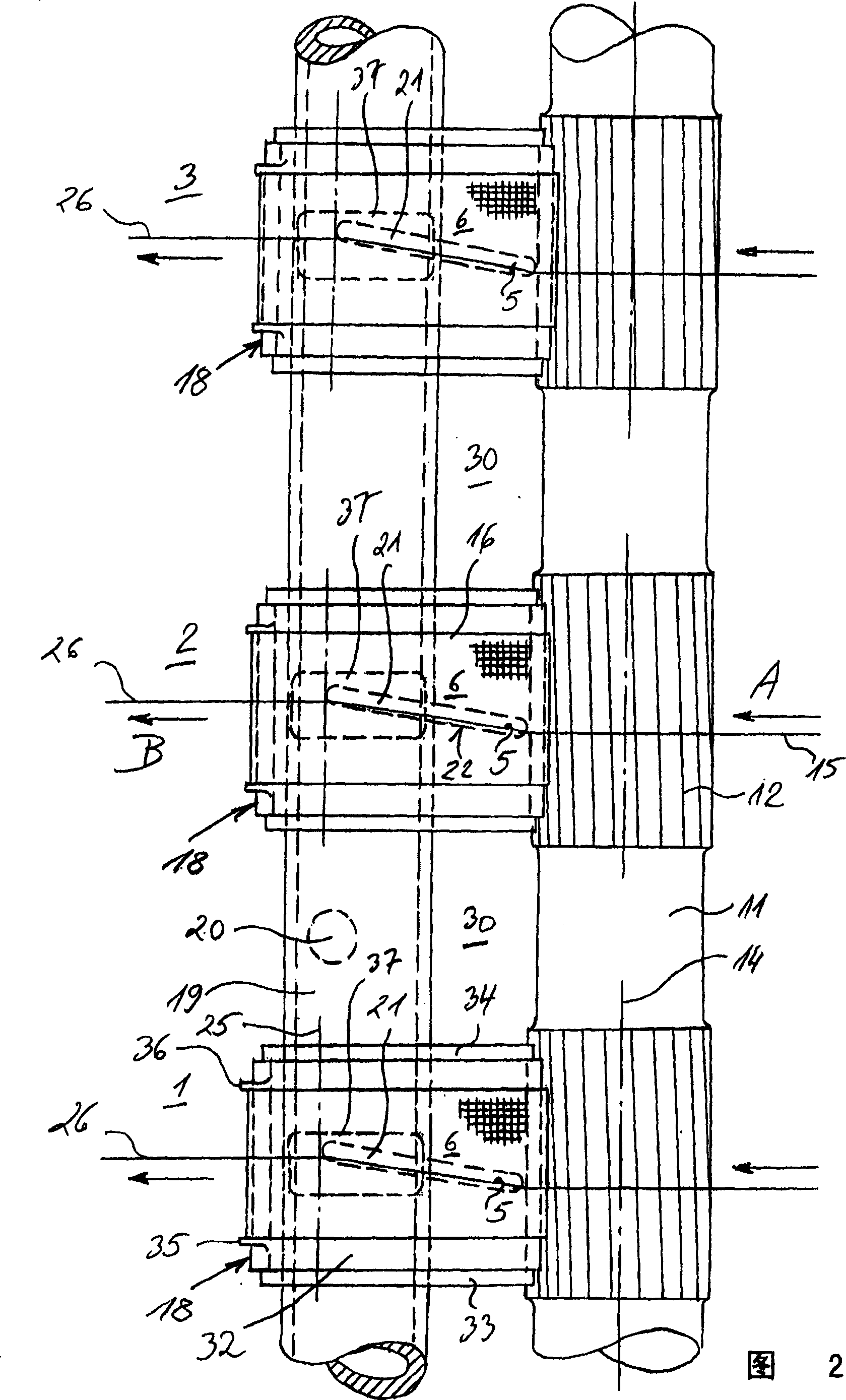

[0014] according to figure 1 The spinning machine shown in the part of Fig. 2 is firstly a ring spinning frame. Usually, this kind of spinning machine has many adjacently arranged spinning positions according to the longitudinal direction of the machine. From Fig. 2, it can be seen that three Spinning positions 1, 2 and 3.

[0015] Each spinning position 1, 2, 3... has a drafting unit 4, but in figure 1 Only its terminal area is drawn in the drawing, and there is a collection area 6 for bundling the drawn but untwisted fiber strip 5, which is located downstream of the drafting device 4. The other components of the spinning positions 1, 2, 3... are not shown.

[0016] Each drafting unit 4 has a pair of front rollers 7, and an apron roller 10 for guiding the lower apron 8 and the upper apron 9 mounted upstream of the pair of front rollers. All the other rollers of the drafting device 4 are not shown on the figure.

[0017] The front roller pair 7 has a driven bottom roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com