Hypocycloid pinwheel planetary gearing

A technology of planetary transmission and hypocycloid, applied in the direction of gear transmission, transmission, belt/chain/gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

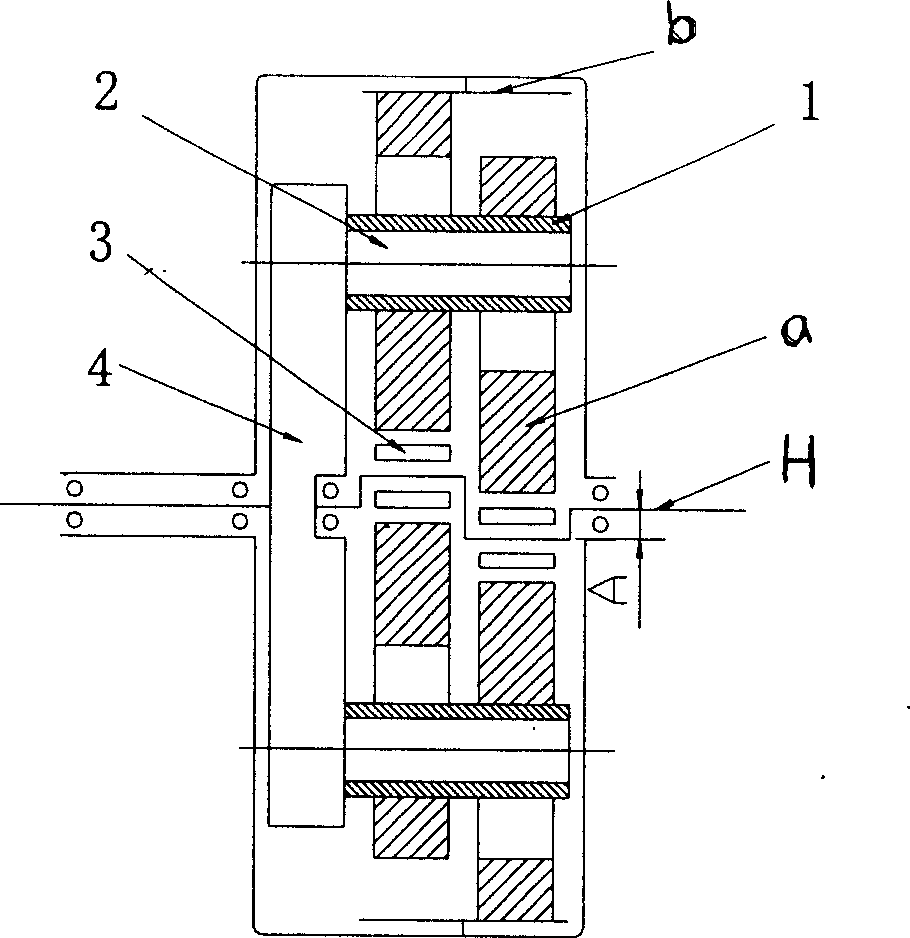

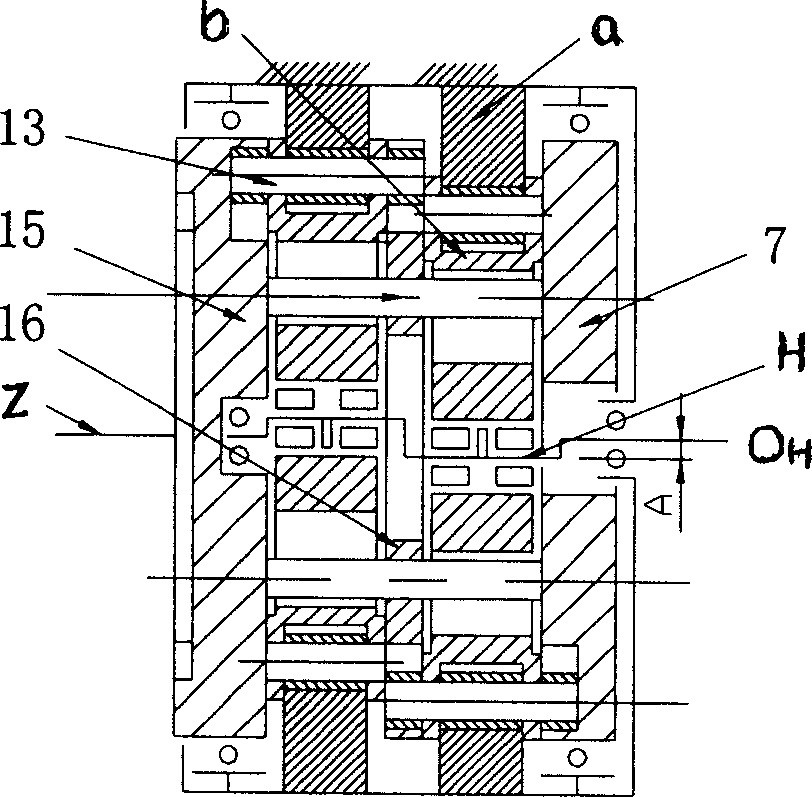

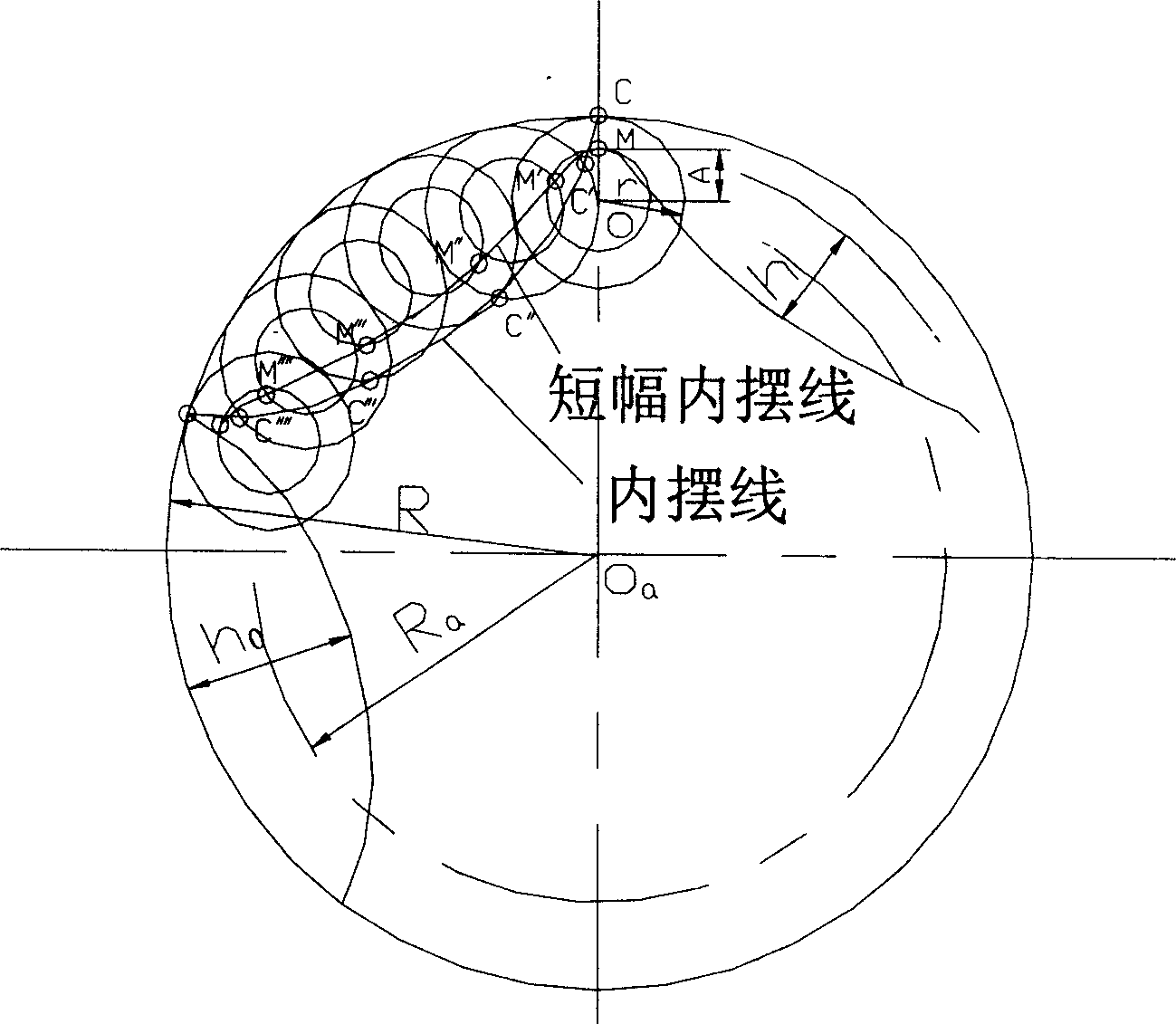

[0062] The hypocycloid planetary transmission is a new type of cycloidal planetary transmission designed on the principle of hypocycloid formation and meshing. The structure and components that make up this transmission device are shown in the appendix Figure 5 .

[0063] The planetary carrier is composed of an input shaft (4) and double eccentric sleeves (5), and the two eccentric directions on the eccentric sleeves (5) are mutually 180°. Usually one end of the input shaft (4) is supported on the back cover (2), and the other end is supported on the front force transmission disc (15).

[0064] The planetary gear is a pin wheel formed by alternately installing short pins (9) (not used when the number of teeth is small) and long pins (13) on the pin rack (8). Usually, pin gear sleeves (10) are installed on the pin gear, and (1-2) rotating arm bearings (6) are installed in a pin gear frame (8). A group of through holes that can pass through the connecting rod (3) are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com