Controlled impedance cable connector

A joint surface, ground plane technology, applied in the direction of conductive connection, connection, circuit, etc., can solve the problems of not easy to change to signal/ground structure, insufficient performance characteristics, increased time and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

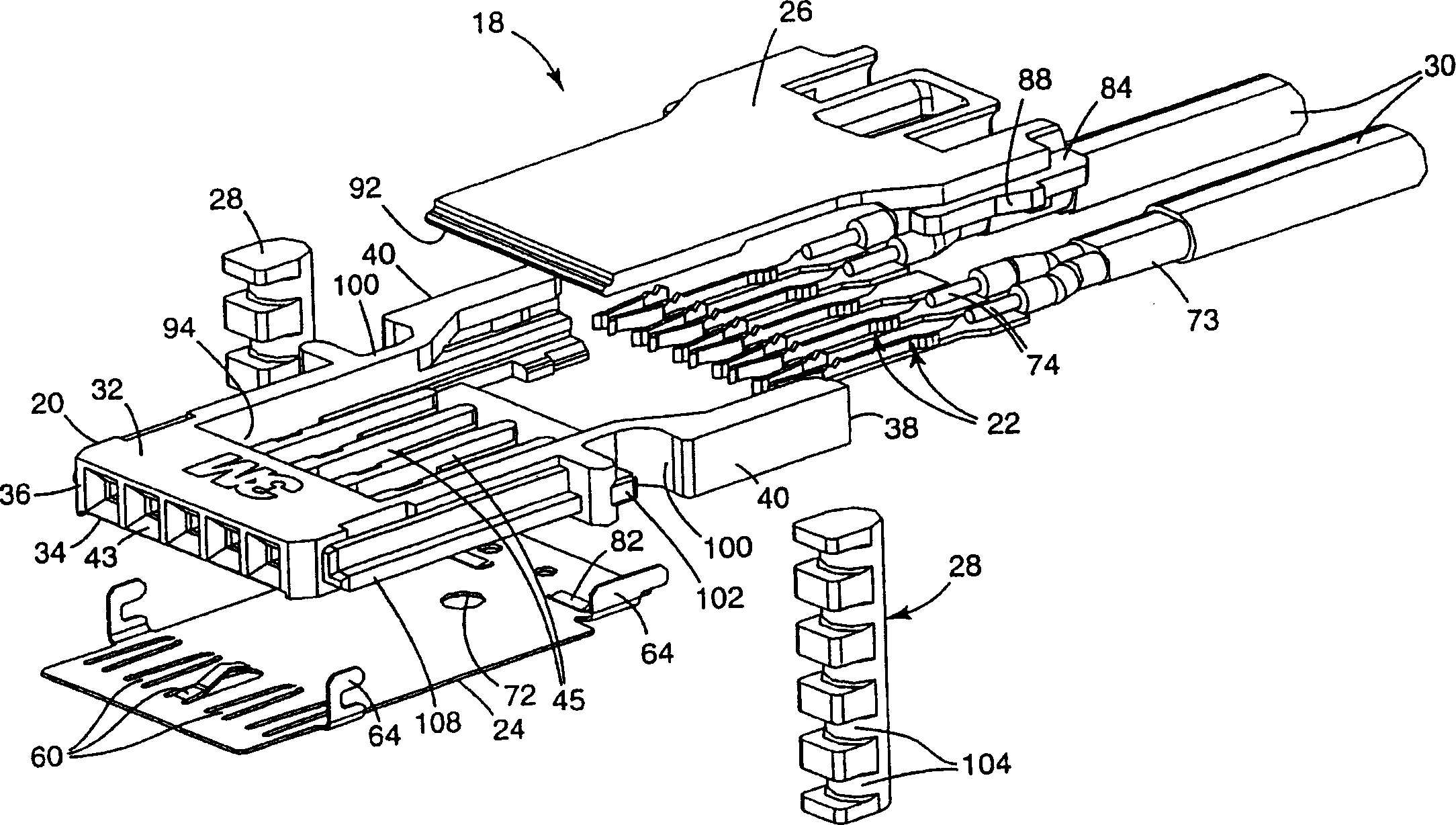

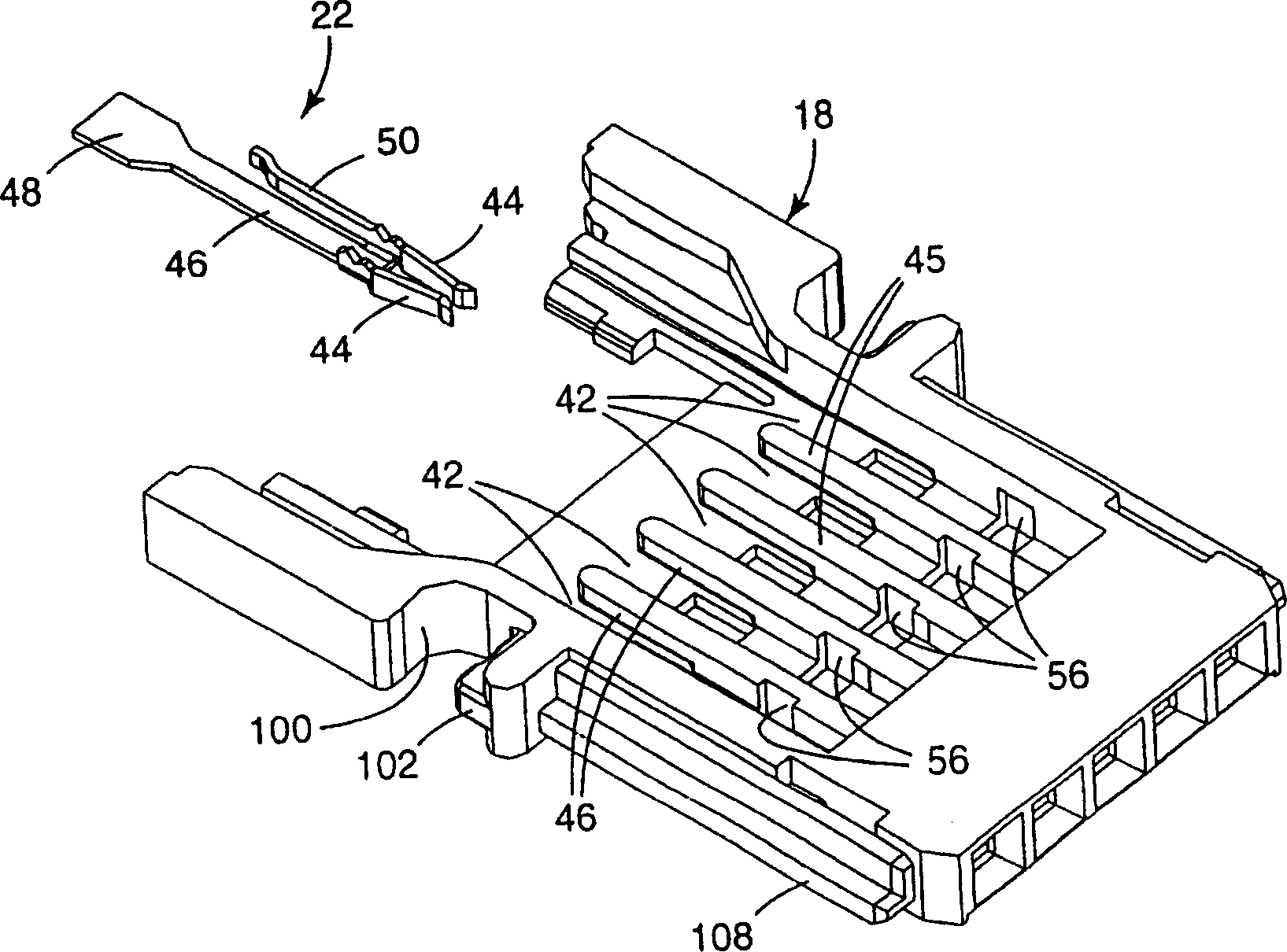

[0018] exist figure 1 The connector 18 of the present invention, shown in exploded view in FIG. 2 , includes a connector body 20 formed of a non-conductive insulating material, a plurality of receptacle contacts 22 , a flat conductive ground plate 24 and a cover member 26 . Retention bar 28 may be used when multiple joint bodies are stacked together. Connector 18 in figure 1 Indicated for use with a pair of twinax cables 30. However, as will be discussed in more detail below, the connector 18 of the present invention may be used with other types of shielded cables, such as coaxial or twisted pair cables.

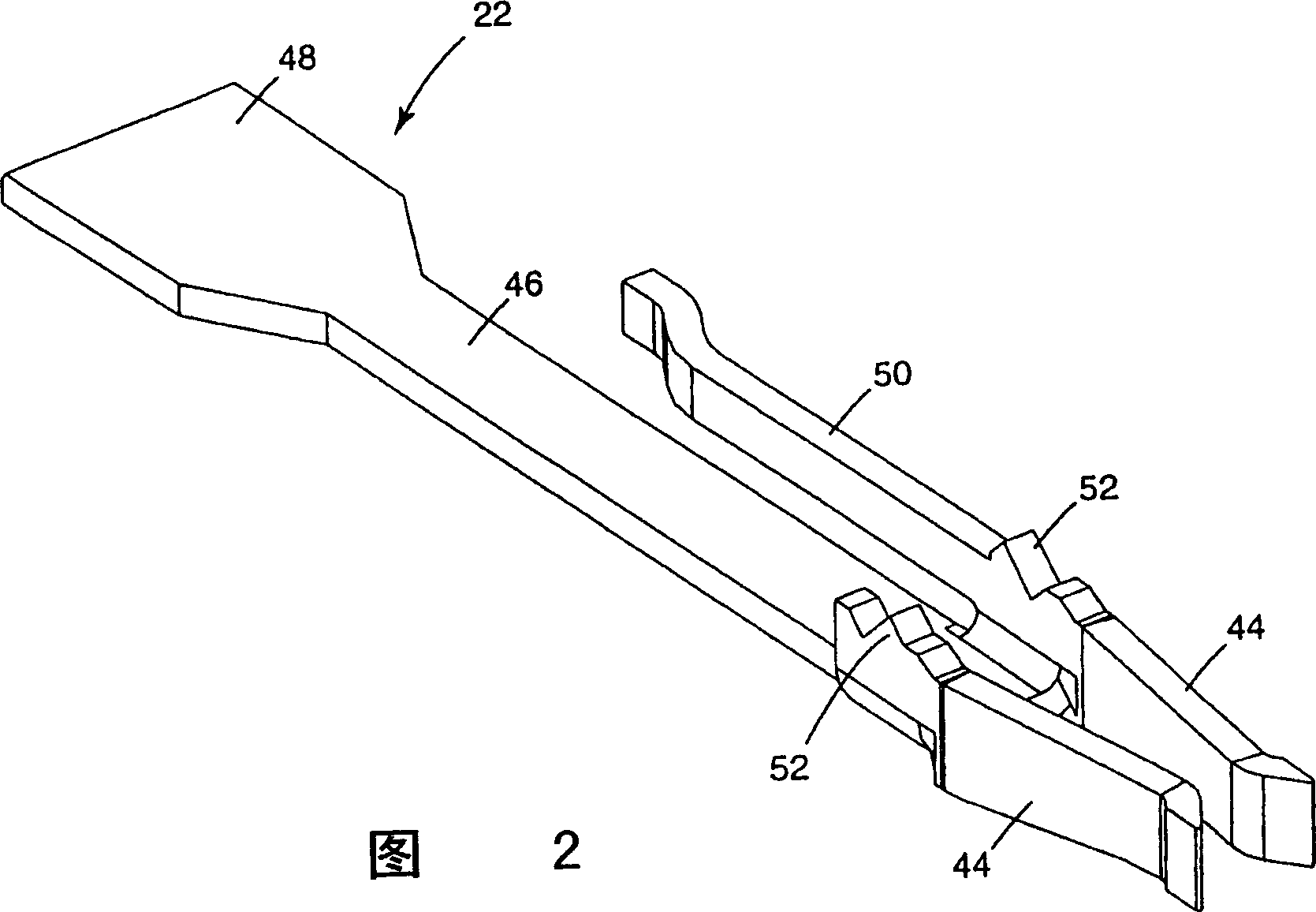

[0019] The fitting body 20 includes a top side 32 and an opposite bottom side 34 . The top side 32 and the bottom side 34 are bounded by a leading edge 36 , a trailing edge 38 and two longitudinal side edges 40 . The top side 32 of the joint body 20 includes a plurality of channels 42 separated by ribs 45 extending from an opening 43 in the leading edge 36 toward the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com