Centrifugal dust separator

A dust separator and centrifugal technology, applied in the direction of the swirling flow can reverse the axial direction of the device, swirl device, etc., can solve the problems of large volume, poor purification effect, large wind resistance, etc., to achieve high separation efficiency, occupying The effect of small floor area and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

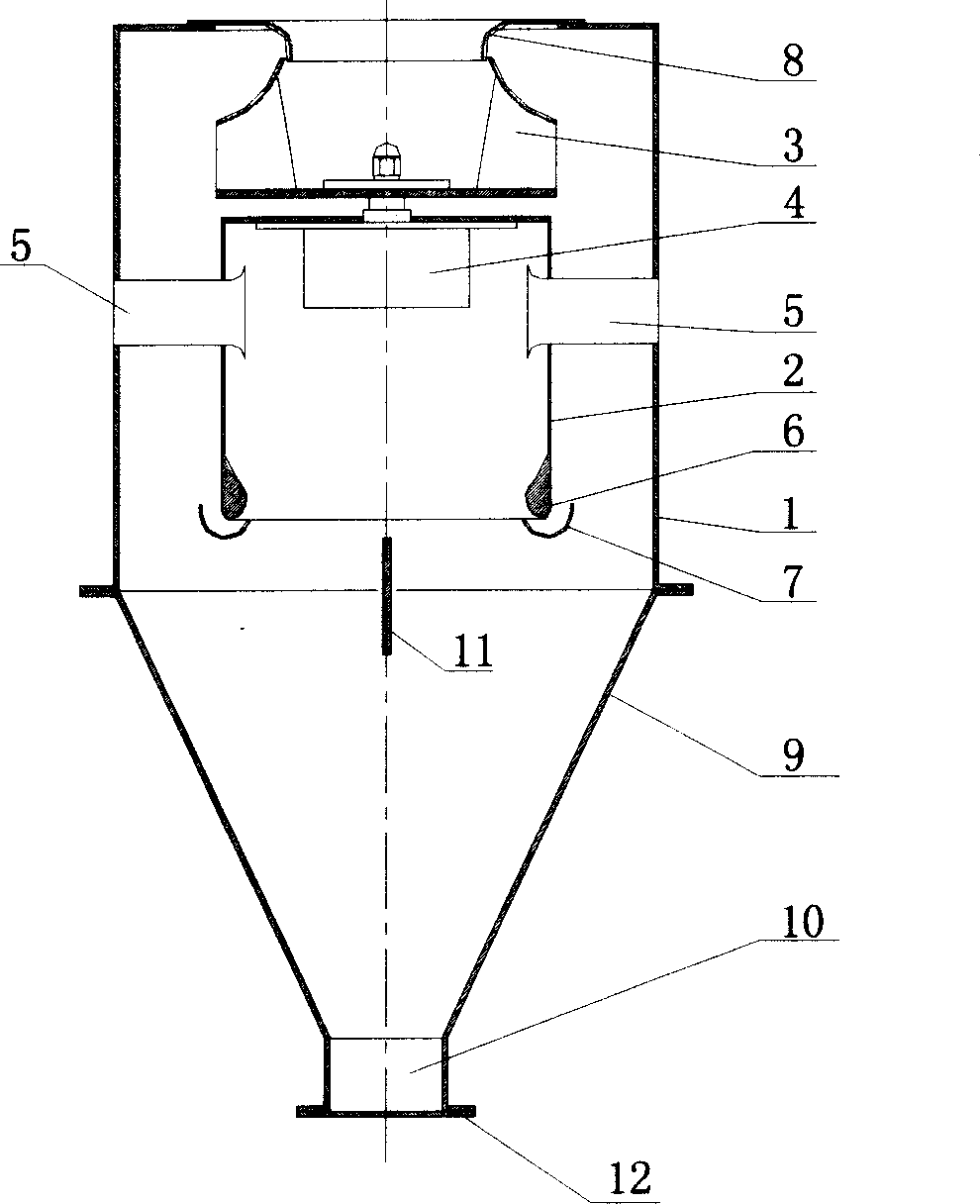

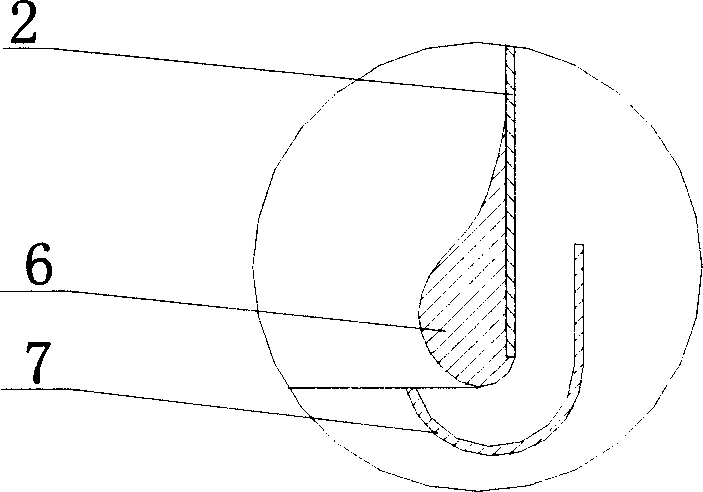

[0015] The structure of the centrifugal dust separator provided by the present invention is as follows figure 1 As shown, it is composed of two concentrically arranged circular cylinders-an outer cylinder 1, an inner cylinder 2, and a cone-shaped dust collecting bucket 9 connected to the bottom of the outer cylinder 1. The upper part of the inner cylinder 2 is installed with a centrifuge The air inlet of the booster fan 4 and the booster fan impeller 3 is provided with an arc-shaped current collector 8. A streamlined deflector 6 is arranged at the air inlet at the bottom of the inner cylinder 2, and an annular guide vane 7 is arranged at the turning point of the inlet gas of the inner cylinder 2. Located at the center of the annular guide vane 7, a straight splitter 11 is fixed on the bottom end of the inner wall of the outer cylinder 1. A num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com