Braking device and electric tool contg. the same

A technology of brake device and brake disc, applied in the combination of coupling and brake, mechanical equipment, etc., can solve the problems of high precision requirements and slippage of parts, and achieve the effect of small braking impact force, safe operation, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

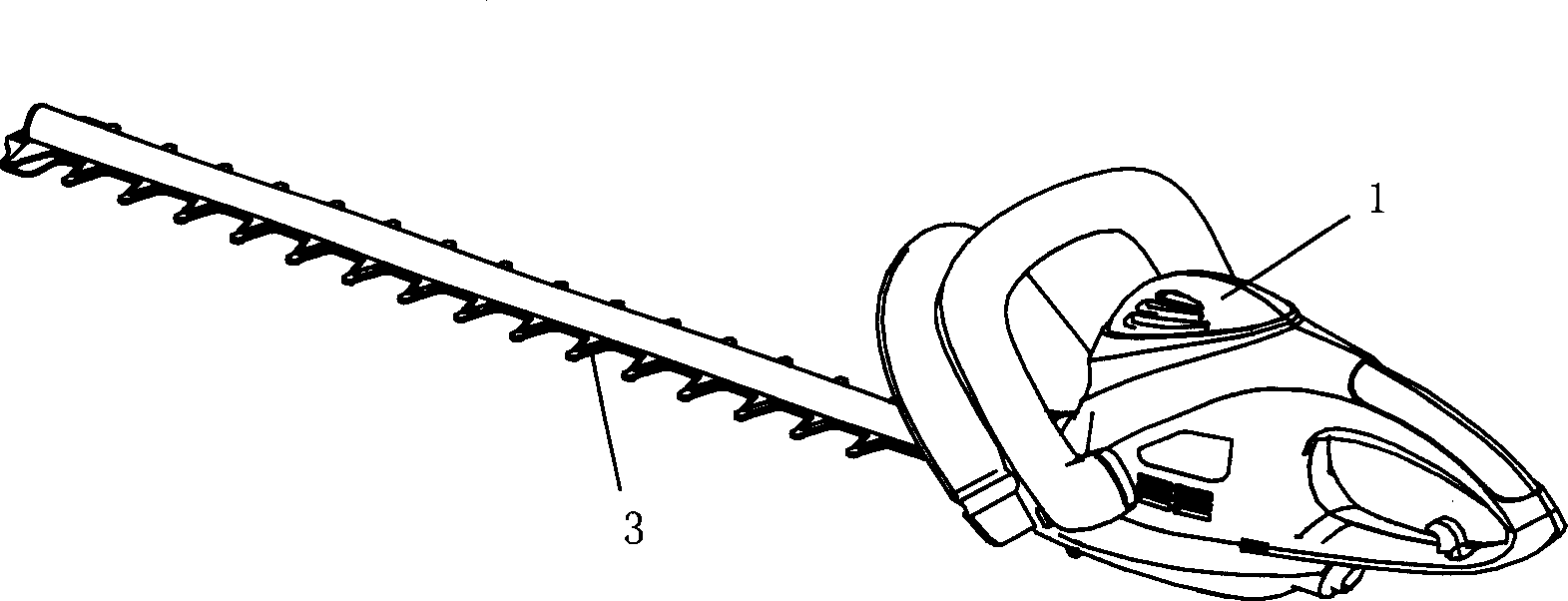

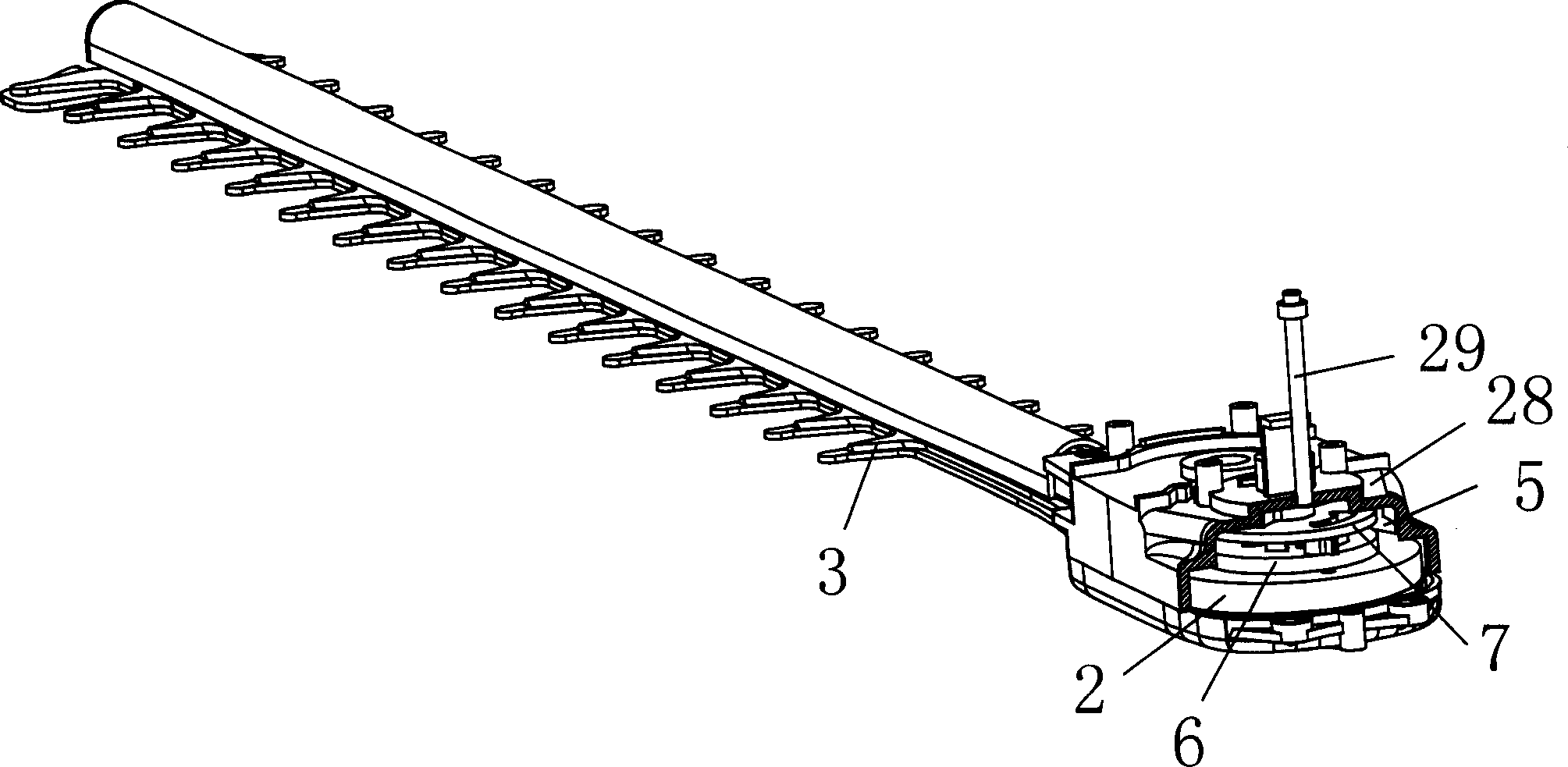

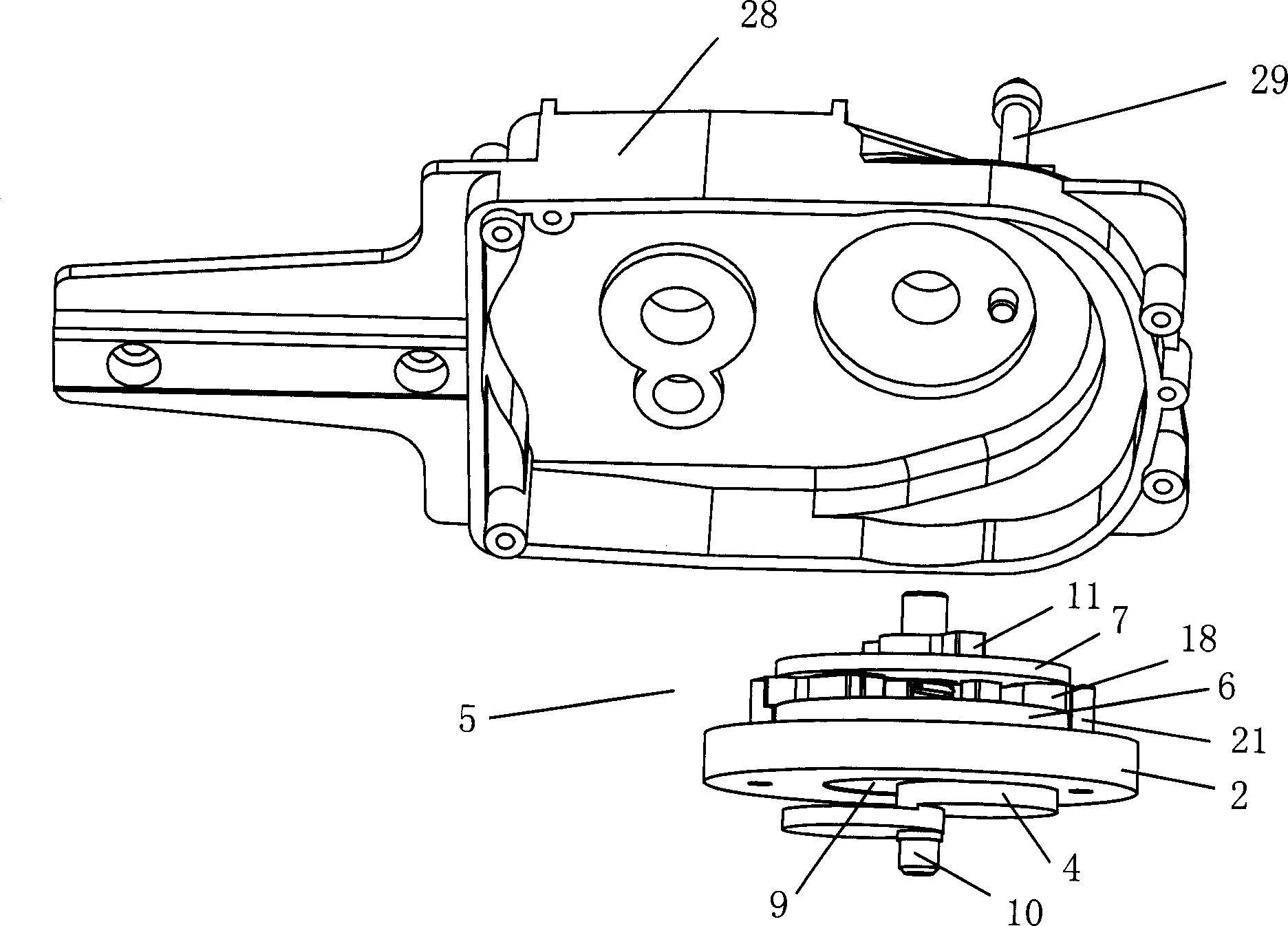

[0022] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a braking device and an electric tool containing the braking device include a large gear 2 driven by a driving device 1, the large gear 2 drives the eccentric block 4 through the clutch device 5, the eccentric block 4 drives the blade 3 to work, and the clutch device 5 It includes the eccentric block 4 located below the large gear 2, the brake disc 6 located above the large gear 2 and the holding disc 7 above the brake disc 6, the center of the large gear 2 is provided with a rotating hole 8, and the upper part of the eccentric block 4 is fixed with a rotating disc 9 , the rotating hole 8 is set outside the rotating disk 9, and the rotating shaft 10 is fixed on the rotating disk 9, and the rotating shaft 10 passes through the brake disc 6 and the holding disc 7 in turn upwards, and the rotating disc 9 and the braking disc 6 are connected and fixed by the connecting pin 25, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com