Net like heat pipe and its mfg. method

A manufacturing method and mesh technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of inconvenient bending or flattening of heat pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

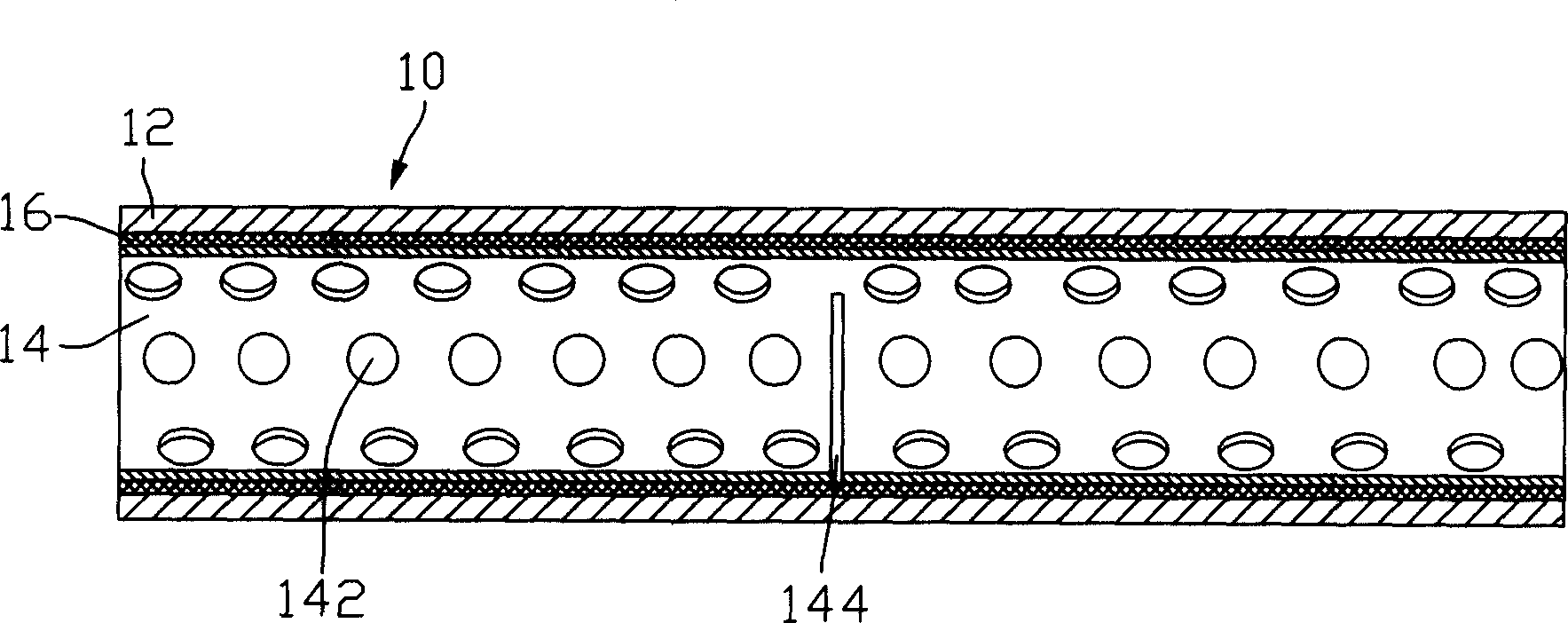

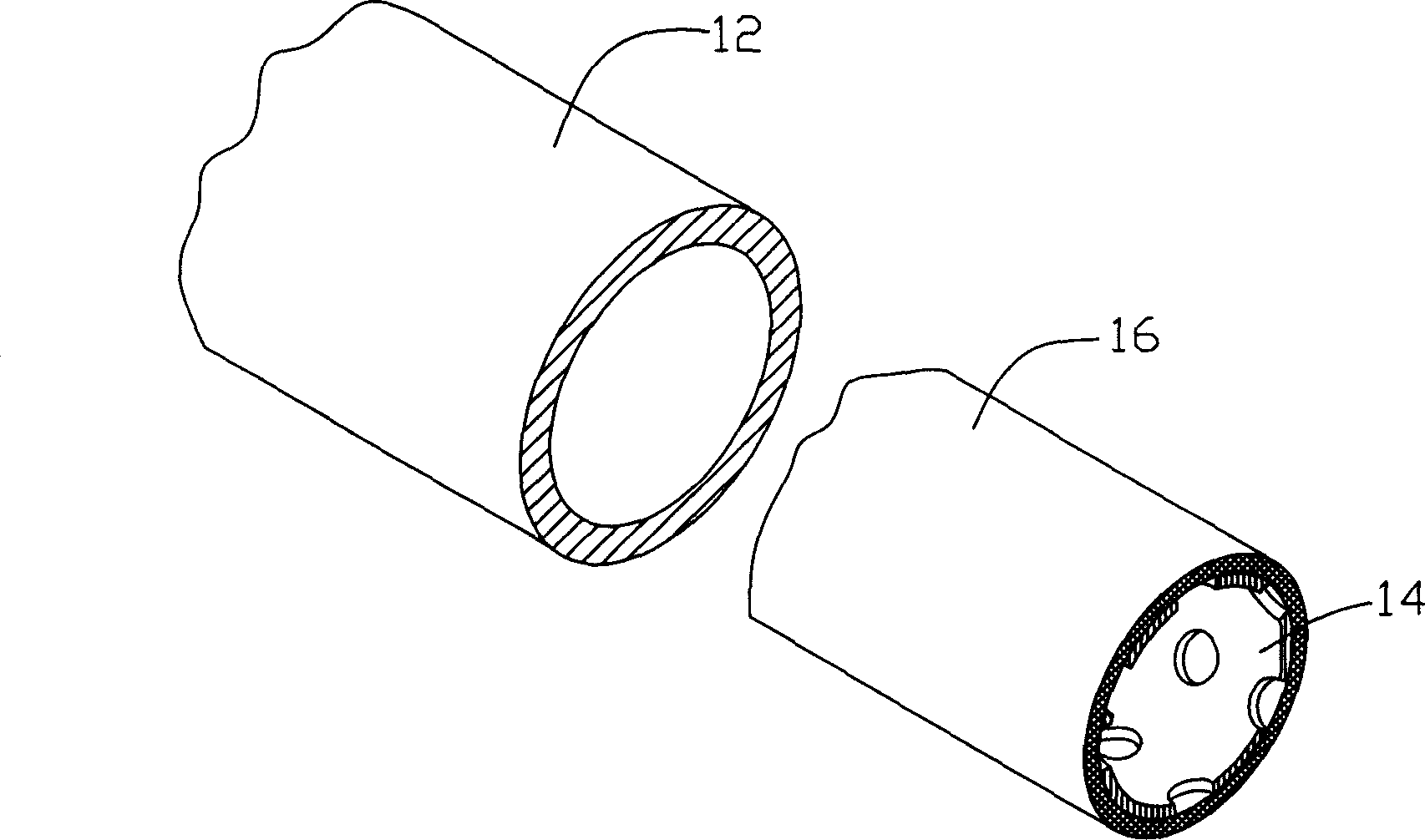

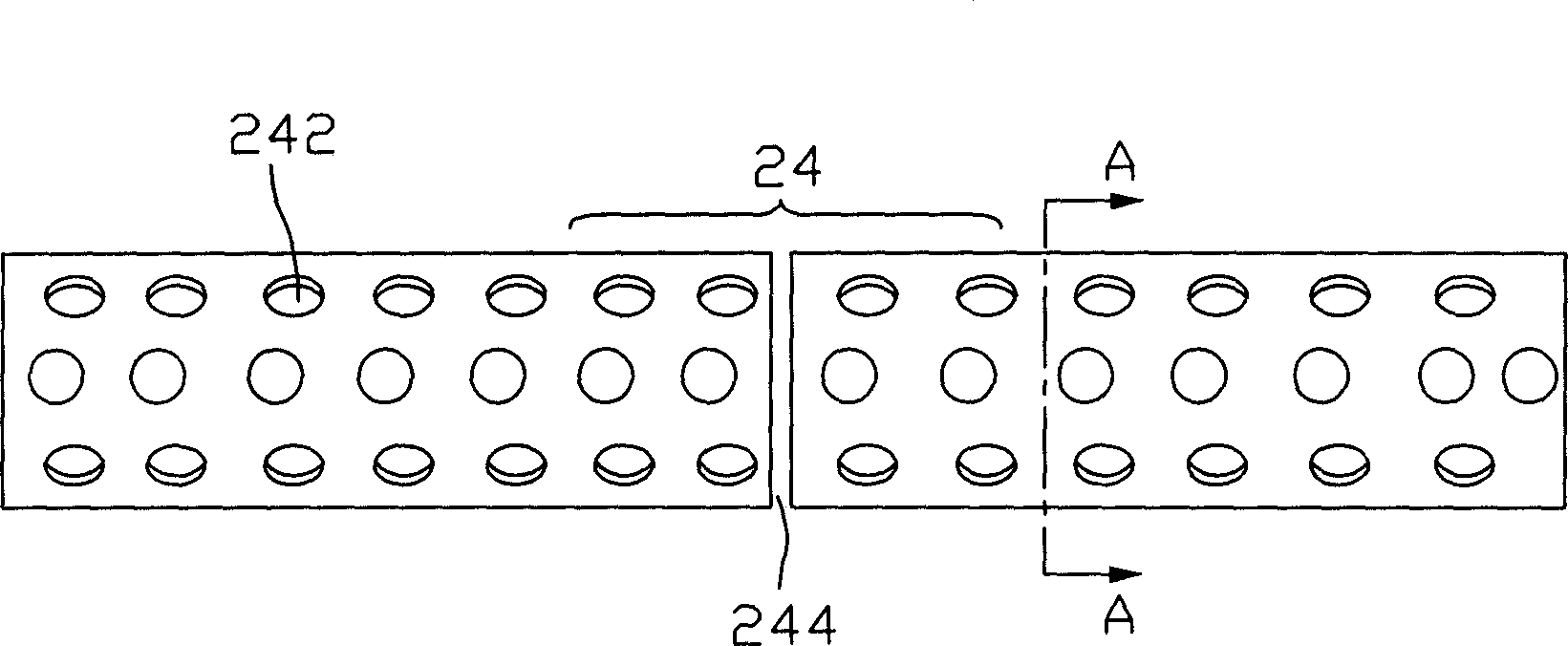

[0017] figure 1 It is a schematic axial cross-sectional view of the first embodiment of the mesh heat pipe of the present invention. The heat pipe 10 includes an outer pipe 12, an inner pipe 14, and a mesh capillary structure layer sandwiched between the outer pipe 12 and the inner pipe 14. 16. Wherein, the outer tube 12 is made of a metal with good thermal conductivity, such as copper, and the inner tube 14 provides a balanced external tension pressure on the capillary structure layer 16 arranged on the inner wall of the outer tube 12, so that the capillary structure layer 16 is integrally tight. It is pasted on the inner wall of the outer tube 12 so as to provide a good and effective heat transfer channel between the outer tube 12 and the working liquid (not shown) in the tube. The surface of the inner tube 14 is provided with a plurality of circular holes 142 through which the working liquid filled in the tube can pass through the holes 142 and communicate with the capilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com