Handling large, heavy workpieces using gantry robots with two robot arms

A robotic arm and gantry technology, applied in the system field of remote control machinery, can solve the problems of complicated installation, reduced load, long debugging time, etc., and achieve the effect of saving workshop floor space, simplifying tools, and improving process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

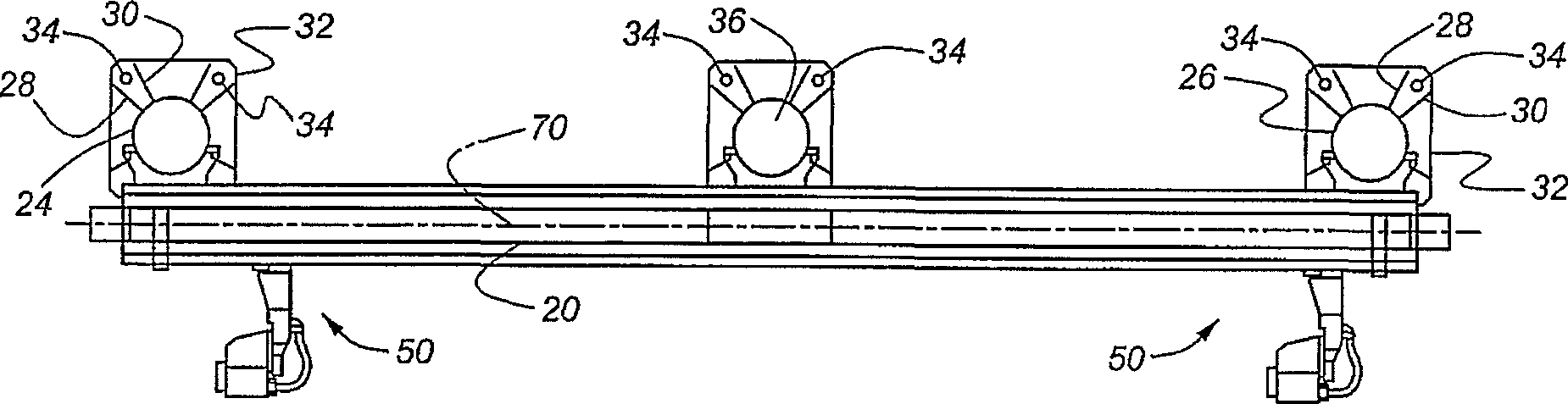

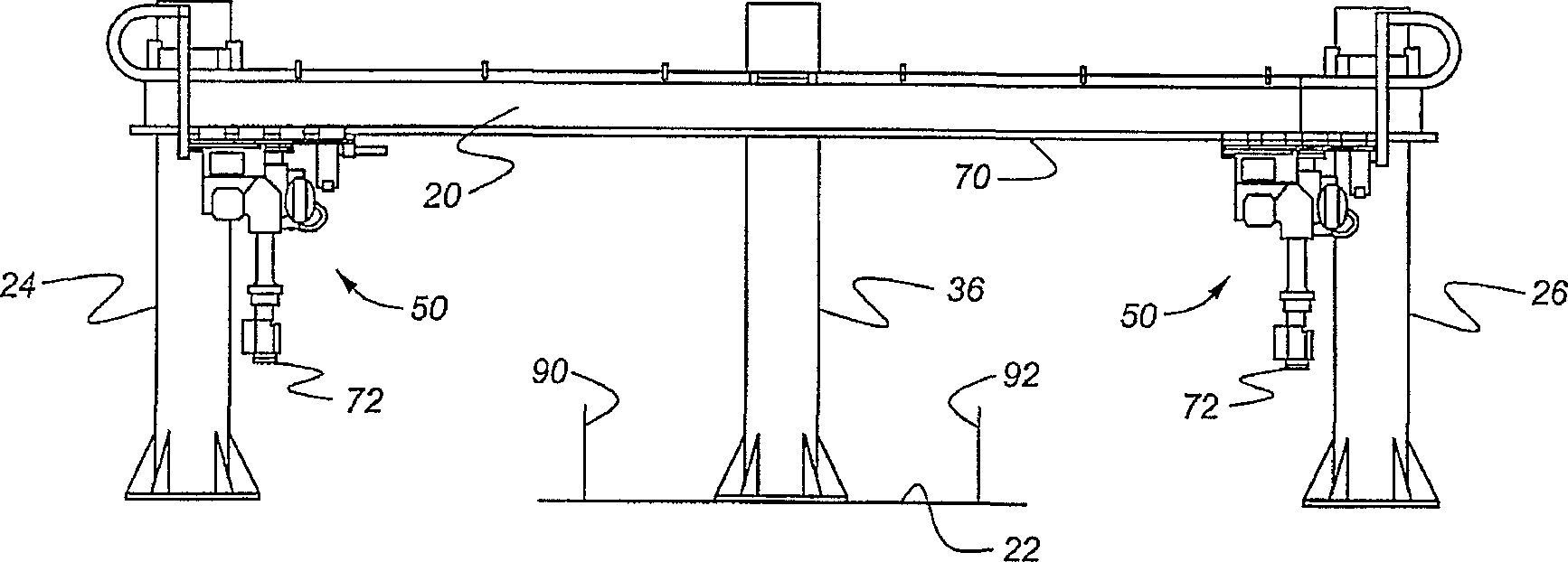

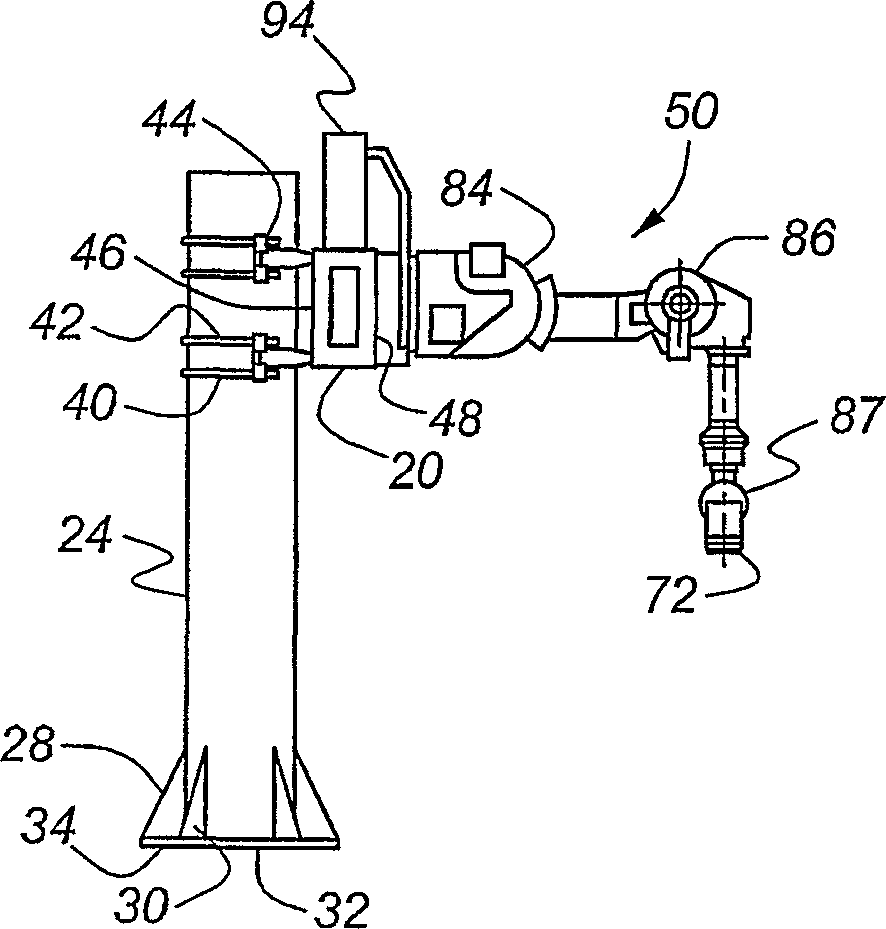

[0022] Figure 1-4 A guide rail 20 suspended above a factory floor 22 work area is depicted. The rail 20 is supported near both ends by posts 24, 26, preferably in the shape of hollow cylindrical tubes. A pair of flanges 28, 30 are located at the bottom of each column, extending radially from the column, and the flanges are welded to the column and the chassis 32 together. Screws 34 located around the periphery of the chassis 32 secure the chassis 32 to the floor 22, or to a support surface at or near the level of the floor. When the span between the columns 24 , 26 exceeds a preset length, at least one additional column 36 can be added between the columns 24 , 26 at both ends to provide intermediate support for the guide rail 20 .

[0023] image 3 and 4 The guide rail 20 is depicted affixed to the columns 24, 26 with a short distance apart by pairs of U-shaped bolts 40, 42 which tighten the circular profile of the columns and are secured by anchors 44 threaded over the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com