Seal mechanism for fluid machine

A technology of fluid machinery and sealing mechanism, which is applied in the field of centrifugal pump, fluid machinery sealing mechanism and fluid machinery, and can solve problems such as noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will refer to Figure 4 to Figure 17 A sealing mechanism for a fluid machine according to an embodiment of the present invention will be described. In the drawings, the same or corresponding components are denoted by the same or corresponding reference numerals, and description will not be repeated hereafter.

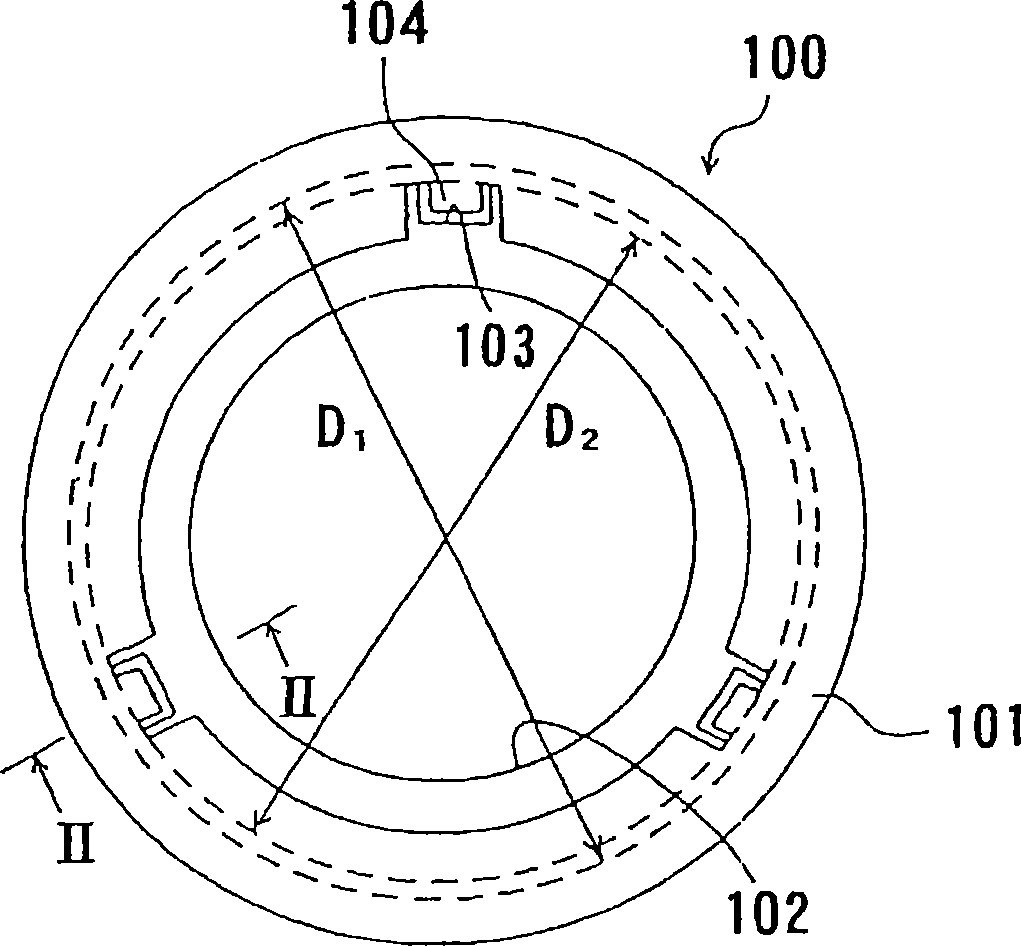

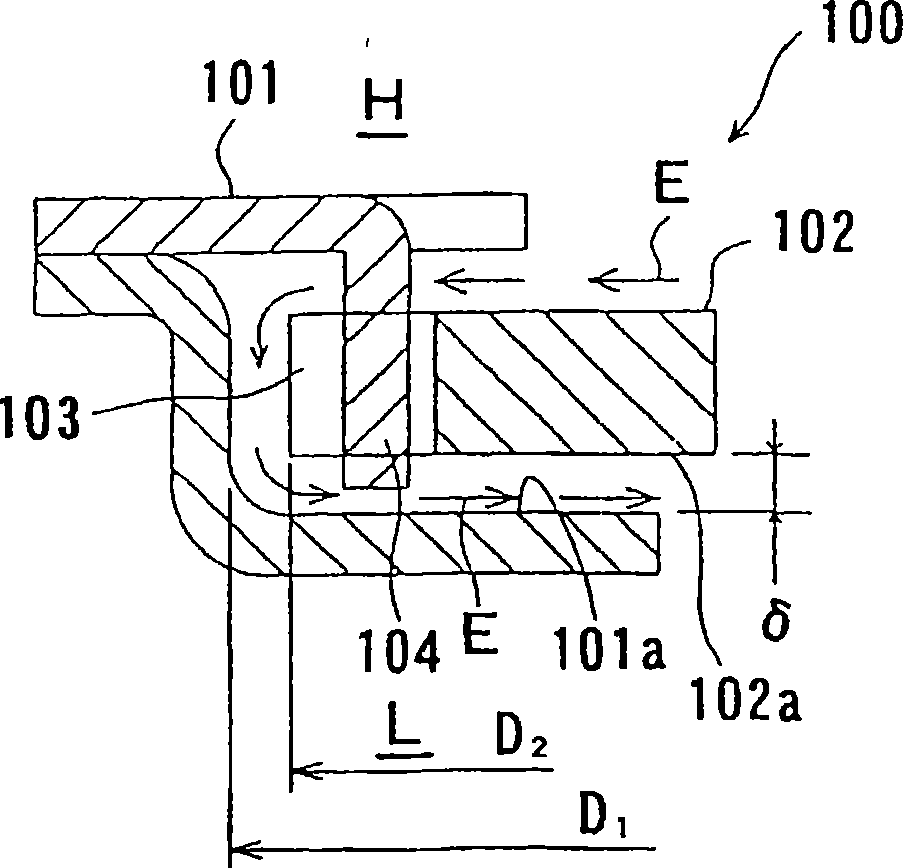

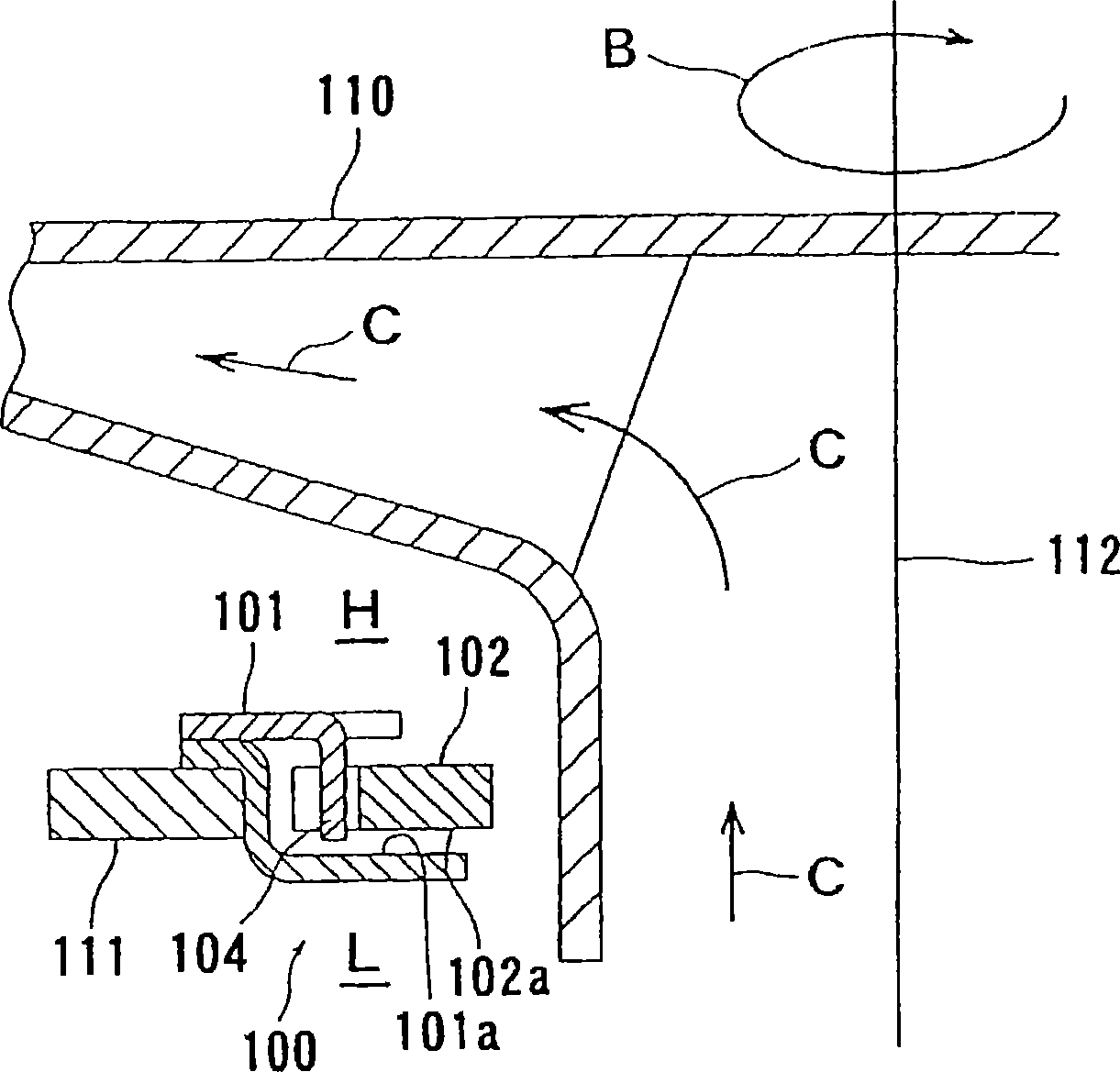

[0038] Figure 4 to Figure 6 The arrangement of the sealing mechanism 10 according to the first embodiment of the present invention is shown. Figure 4 is a top view of the sealing mechanism 10, Figure 5 is along Figure 4 A cross-sectional view obtained at the midline V-V, and Figure 6 is a cross-sectional view showing the sealing mechanism 10 and the impeller 13 of the centrifugal pump. Such as Figure 5 As shown in , the sealing mechanism 10 includes a housing (hood) 11 and an annular back ring (seal) 12 accommodated in the housing 11 .

[0039] The housing 11 includes an upper plate 11a provided on the high-pressure space H side and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com