Flattening process for steel strip

A flat and strip steel technology, applied in the field of steel processing, can solve problems such as the inability to guarantee the shape of the plate and the inability to guarantee the mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

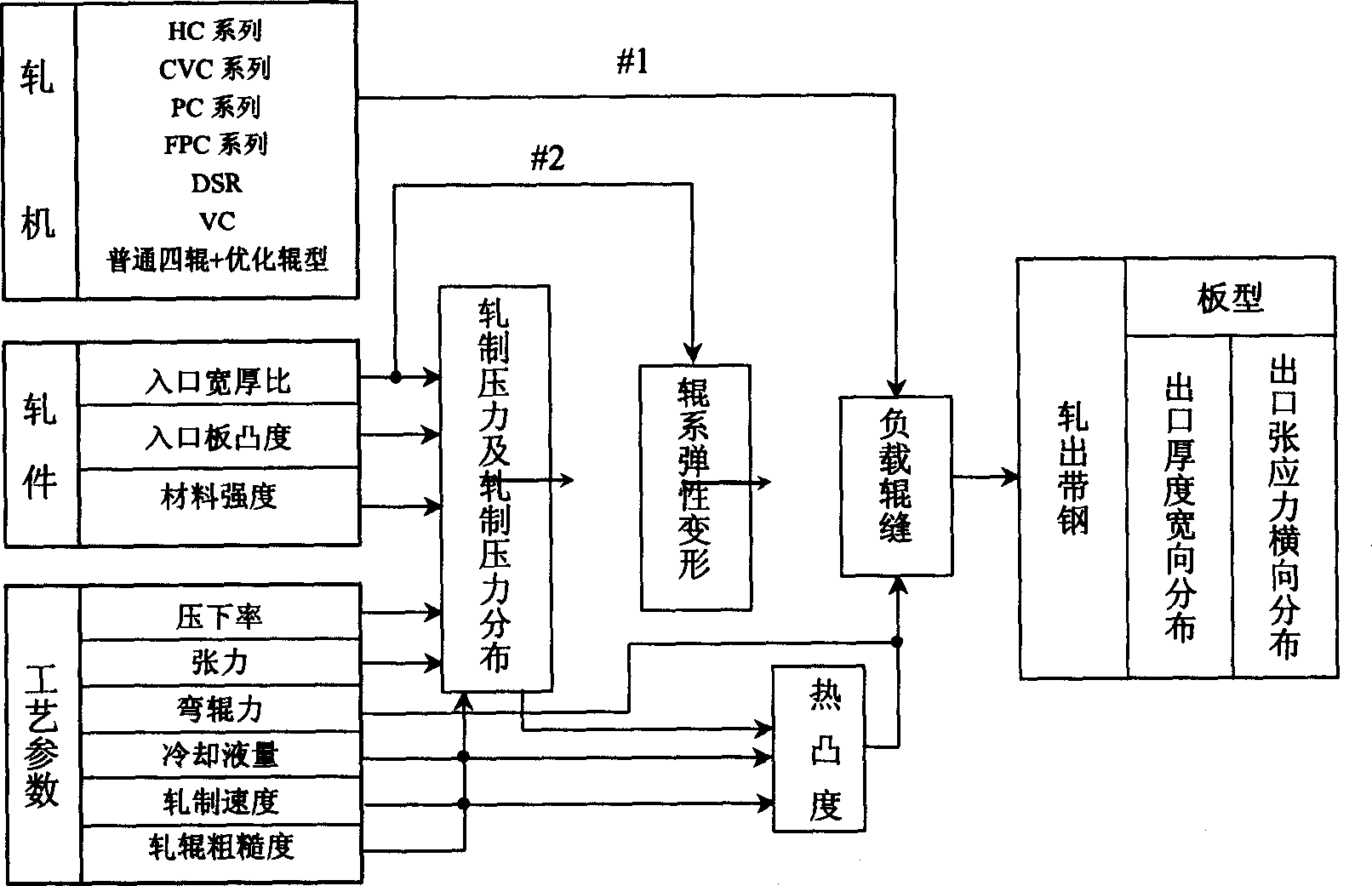

Method used

Image

Examples

Embodiment Construction

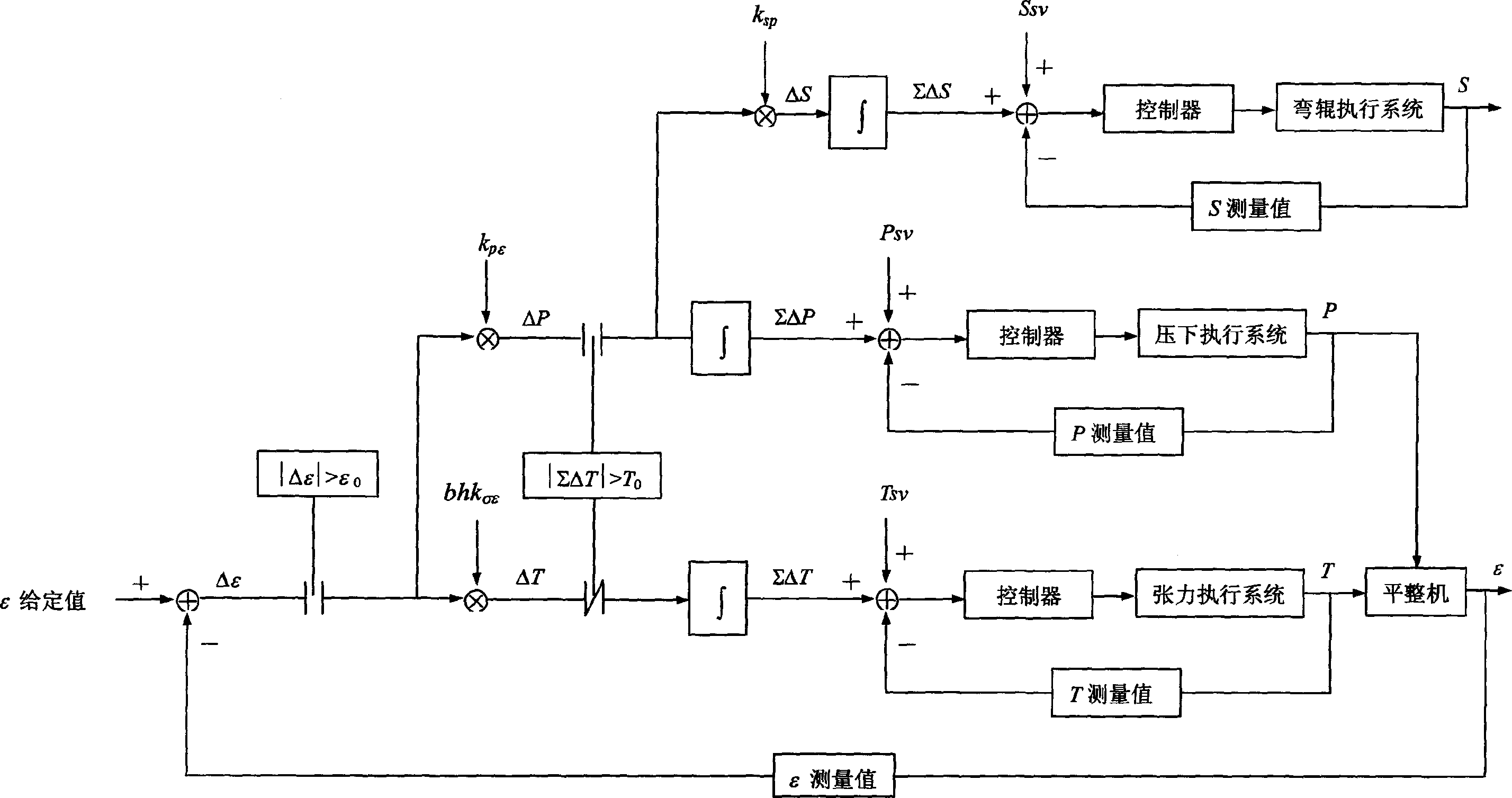

[0056] The leveling process of strip steel of the present invention can be further described as follows:

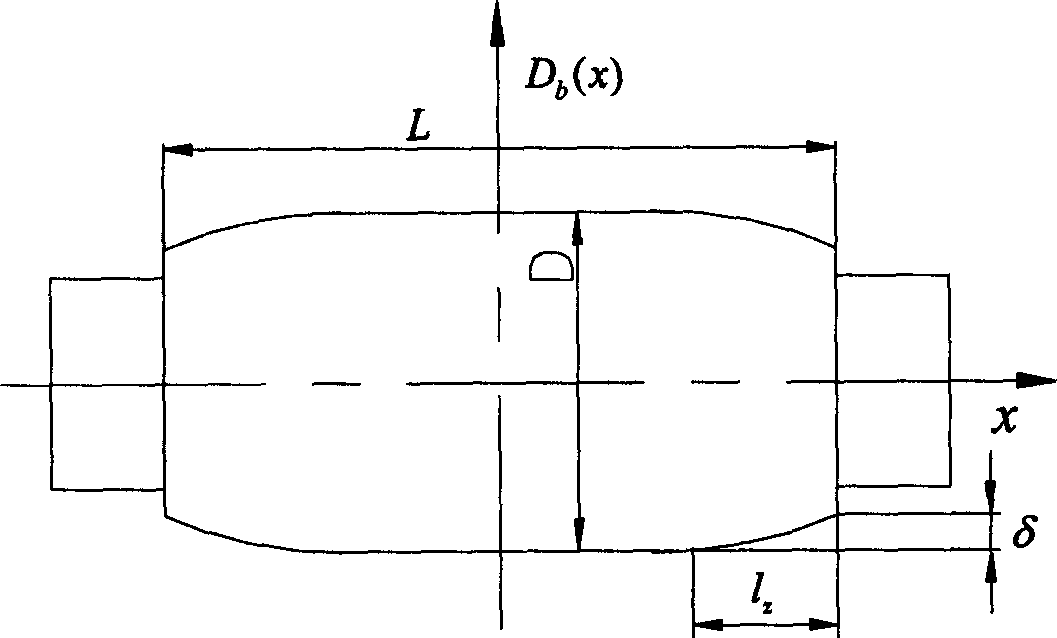

[0057] 1. Optimized design of smoothing roll shape:

[0058] Generally, the range of steel strip varieties and specifications to be produced by the hot-dip galvanizing line is relatively wide, while the shape control means of the skin-pass mill are very limited. Practice has shown that even if the leveling parameters of each specification are optimized with the goal of the best export plate shape, the following situations still often occur:

[0059] A. Since the optimum bending force of certain specifications of strip steel is outside the range of bending force that can be provided by the bending system of the skin pass mill, no matter how the bending force is adjusted during online control, the exit shape will not be good.

[0060] B. Although the optimum bending force of certain specifications of strip steel is within the range of bending force that the skin-pass bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com