Oil-leakage resistant needle bar lower bushing

A technology of preventing oil leakage and needle bar, which is applied in textiles and papermaking, engine components, sewing equipment, etc. It can solve the problem of easy oil leakage of the needle bar and achieve the effect of preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

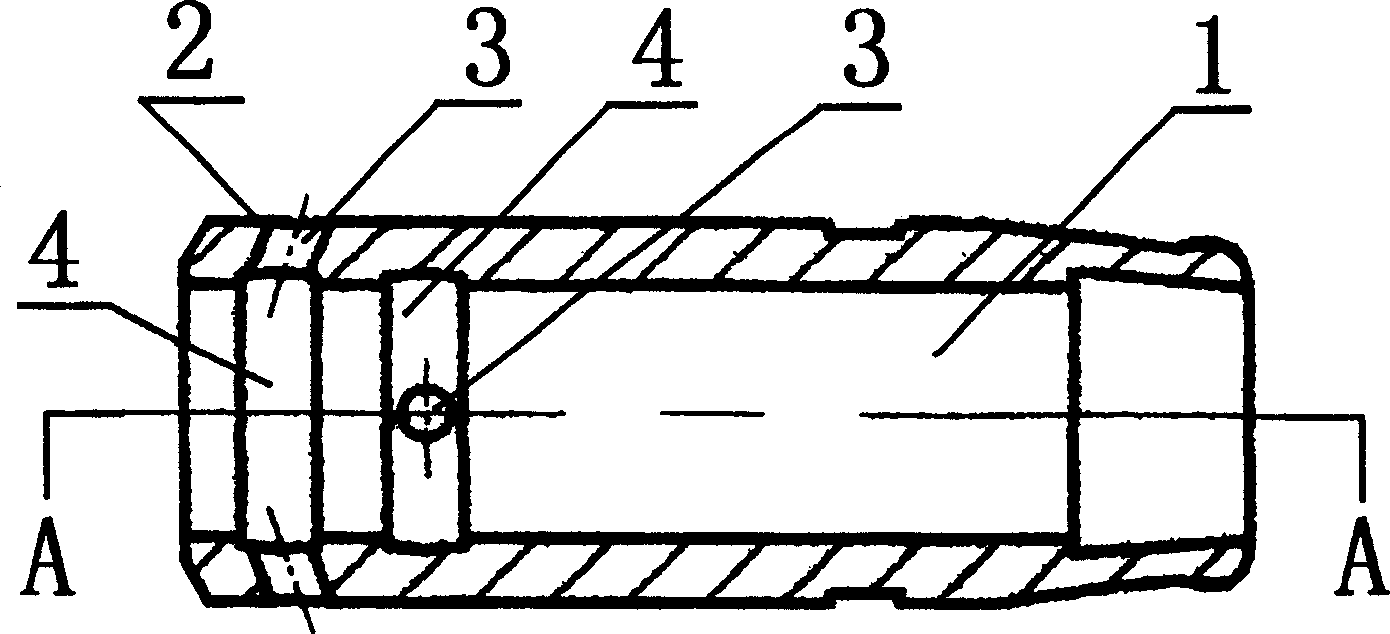

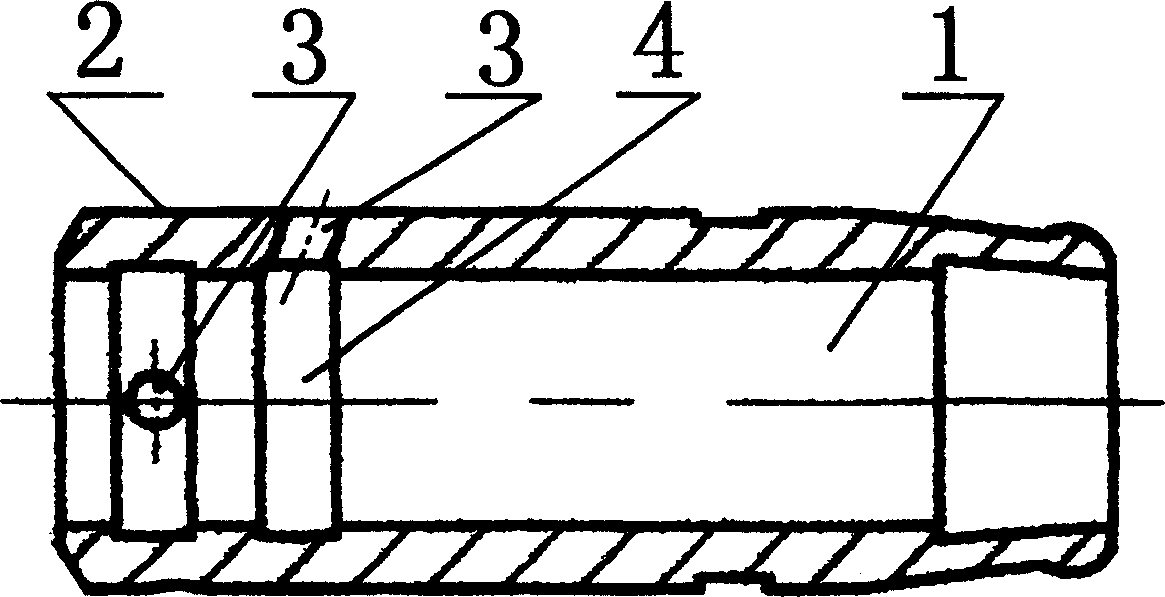

[0010] Embodiment 1, the present invention includes the needle bar lower sleeve body 2 and the needle bar installation hole 1 provided in the middle, and an annular oil scraping groove 4 is arranged on the inner wall of the needle bar installation hole 1, and a needle bar lower sleeve is provided in the oil scraping groove 4. Oil return hole 3 of body 2. By setting the oil scraping groove 4 and the oil return hole 3, it can effectively prevent the phenomenon of oil leakage when the needle bar and the needle bar lower sleeve cooperate to move. refer to figure 1 with figure 2 .

Embodiment 2

[0011] Embodiment 2, in order to enhance the anti-oil leakage effect, the present invention can also set one or more ring-shaped oil scraping grooves 4 in the needle bar installation hole 1 of the needle bar lower casing 2, such as 2-8 channels, preferably 2 -4 roads. An oil return groove can also be set on the outer wall of the needle bar lower sleeve body. refer to figure 1 with figure 2 , all the other are with embodiment 1.

[0012] Obviously, one or more oil return holes 3 passing through the lower casing 2 of the needle bar can be set in each oil scraping groove 4, preferably 2 to 6, such as symmetrically setting 2, or evenly distributing 3 1, 4, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com