Highly stable piezoelectric oscillator

A piezoelectric oscillator, high stability technology, applied in power oscillators, electrical components, printed circuits, etc., can solve problems such as insufficient connection strength and inability to function as an oscillator, so as to increase the amount of solder used and improve The effect of maintaining stability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

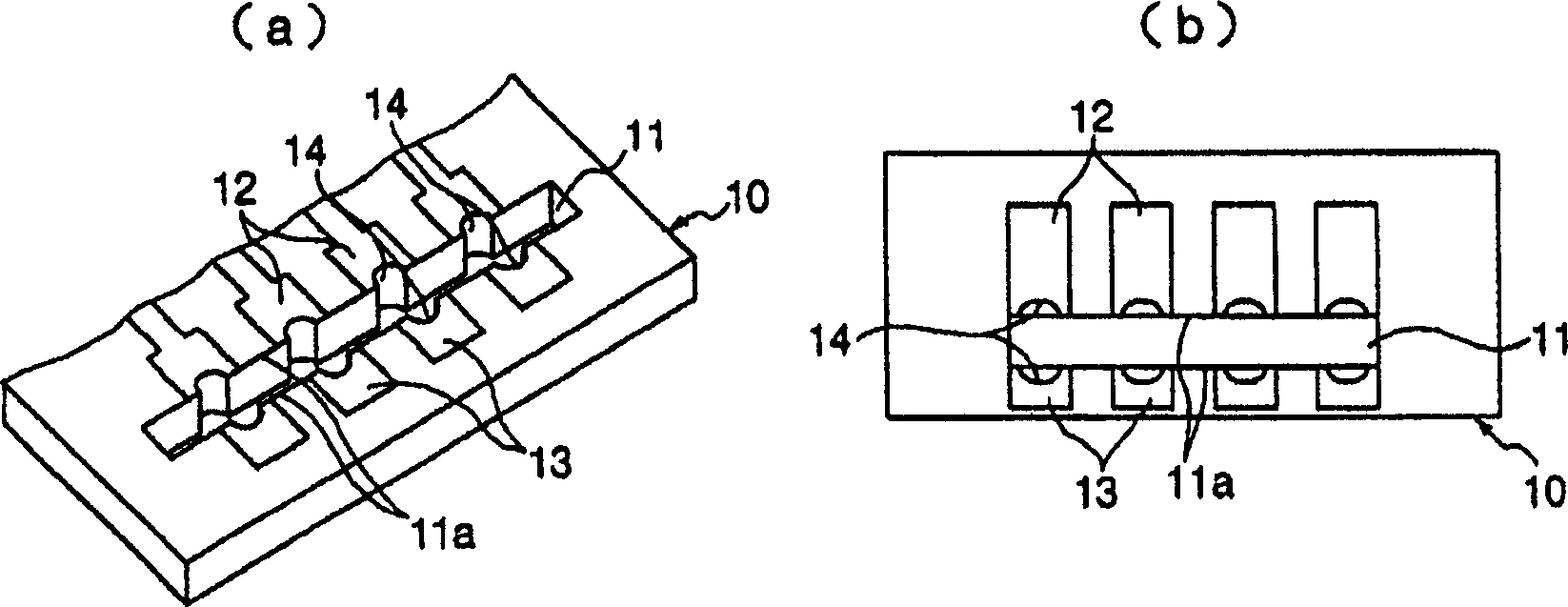

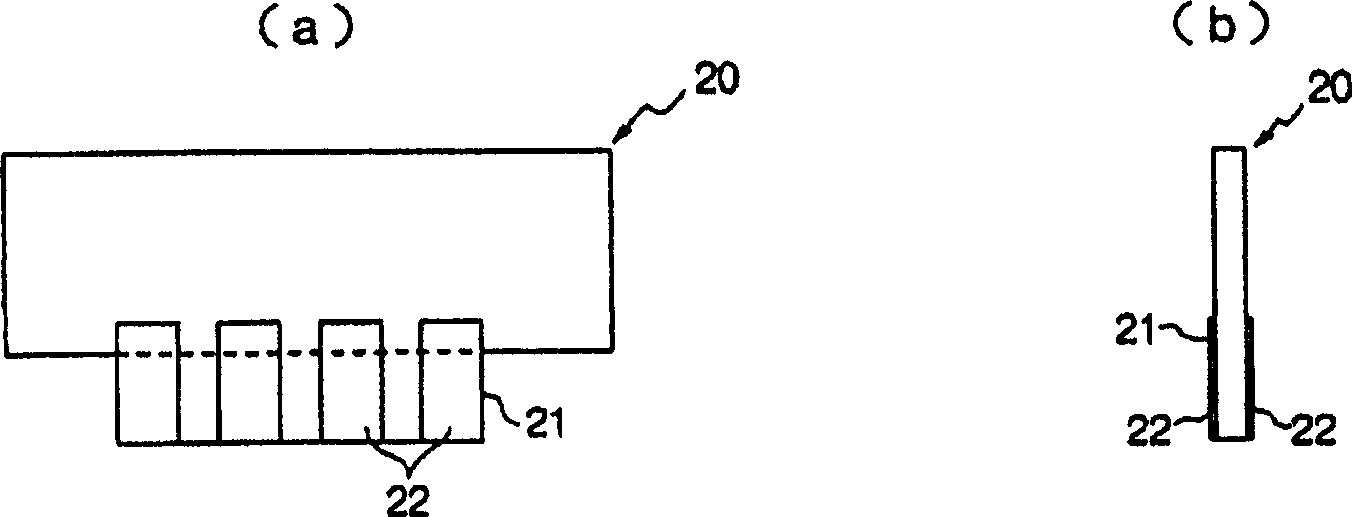

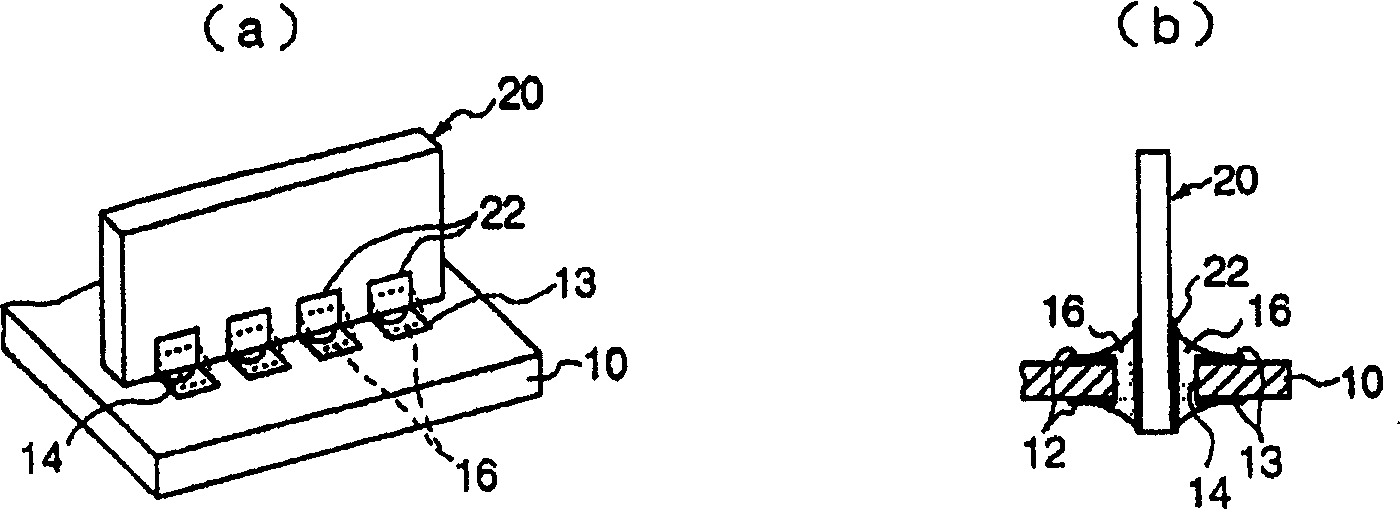

[0025] Next, the highly stable piezoelectric oscillator of the present invention will be described in detail. And, while combining the reference Figure 6 The overall structure of the oscillator is shown while explaining.

[0026] figure 1 (a) and (b) are a perspective view and a plan view showing the structure of the fitting groove portion of the second base printed circuit board. figure 2 (a) and (b) are a front view and a side view which show the structure which erected the printed circuit board. image 3 (a) and (b) are a perspective view and a cross-sectional view showing the state where the vertical printed circuit board is fitted and soldered to the second base printed circuit board.

[0027] figure 1 The shown second base printed circuit board 10 is formed with an elongated rectangular fitting groove 11 penetrating through it, and on the second base along two opposing end edges (longitudinal edges) 11a of the fitting groove 11, The connection pads 12 and 13 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com