Device for electrochemical removal of heat stable salts in desulfurated amine liquid

A technology of desulfurization amine solution and thermal stability, applied in the direction of sulfur preparation/purification, chemical instruments and methods, electrolysis process, etc., can solve the problems of consuming a large amount of chemical reagents, secondary pollution, etc., to reduce costs and avoid intermittent The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

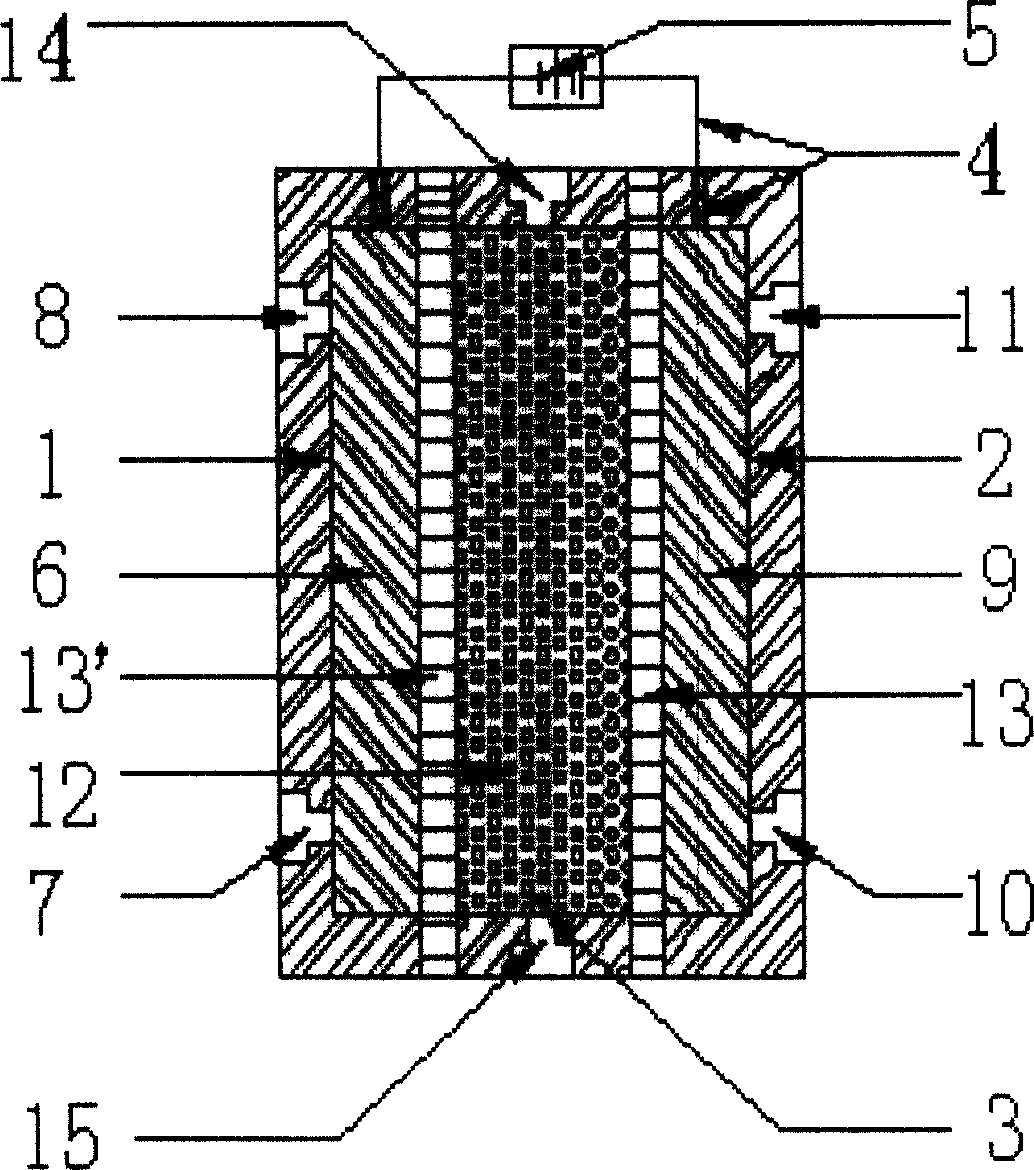

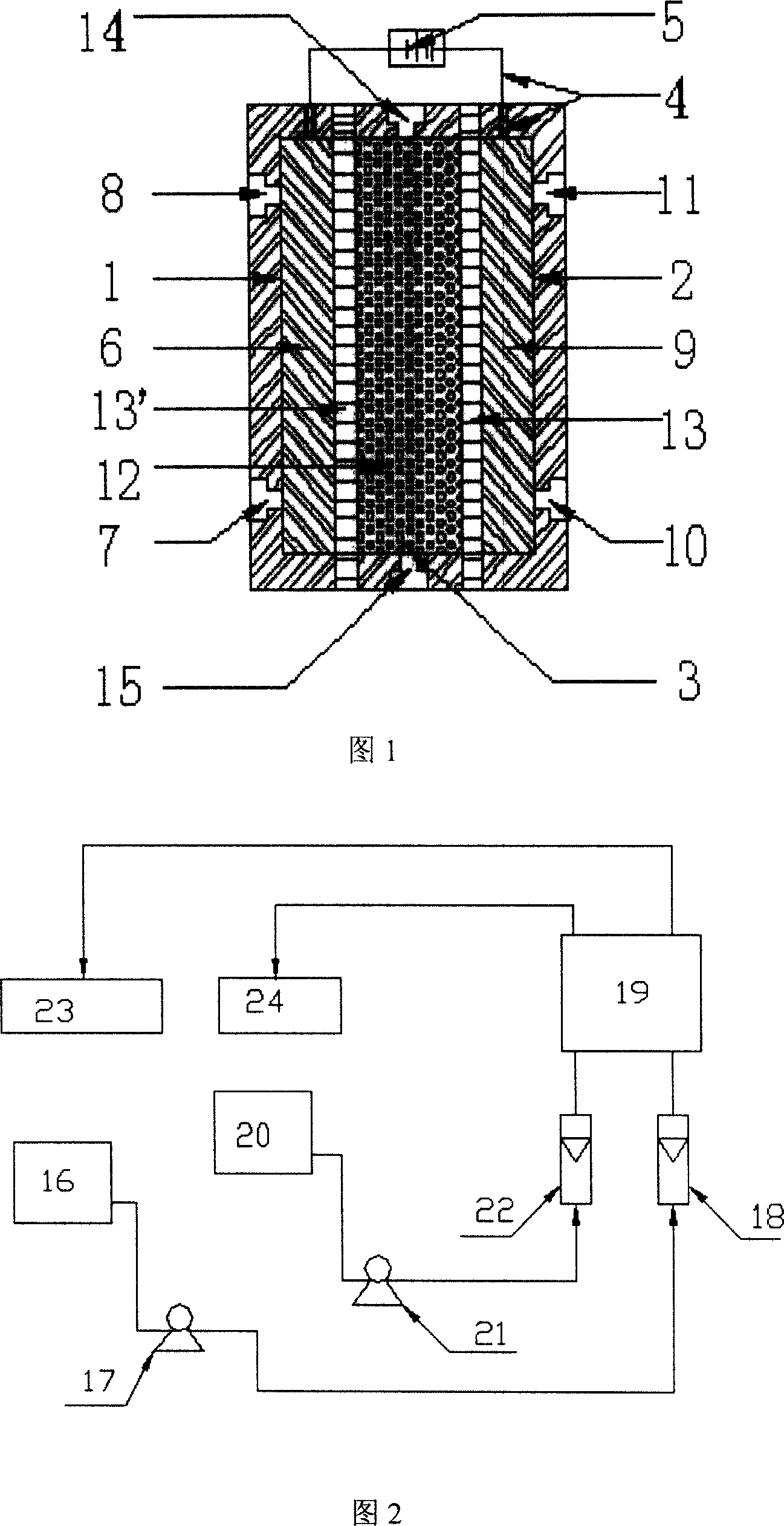

[0017] As shown in Figure 1, the present invention is made up of cathode chamber 1, cathode 6, anode chamber 2, anode 9, ion exchange chamber 3 and constant current source 5, and anode chamber 2 and cathode chamber 1 are all designed as tank-shaped electrode chambers, The anode chamber 2 and the cathode chamber 1 are respectively embedded with an anode 9 and a cathode 6, and the anode 9 and the cathode 6 adopt porous corrosion-resistant metal electrodes, such as platinum electrodes or platinum-plated electrodes, whose length, width and thickness are the same as those of the tank-shaped electrode chamber, and the porous The aperture of the corrosion-resistant metal electrode is 50-200 μm, preferably 100 μm, and the wire 4 connecting the two electrodes of the anode 9 and the cathode 6 is drawn from the top of the cathode chamber 1 and the anode chamber 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com