Two-for-one twister

A two-for-one twister and frame technology, applied in the direction of textiles and papermaking, can solve problems such as abrasion and shedding, affecting yarn strength, and easy yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

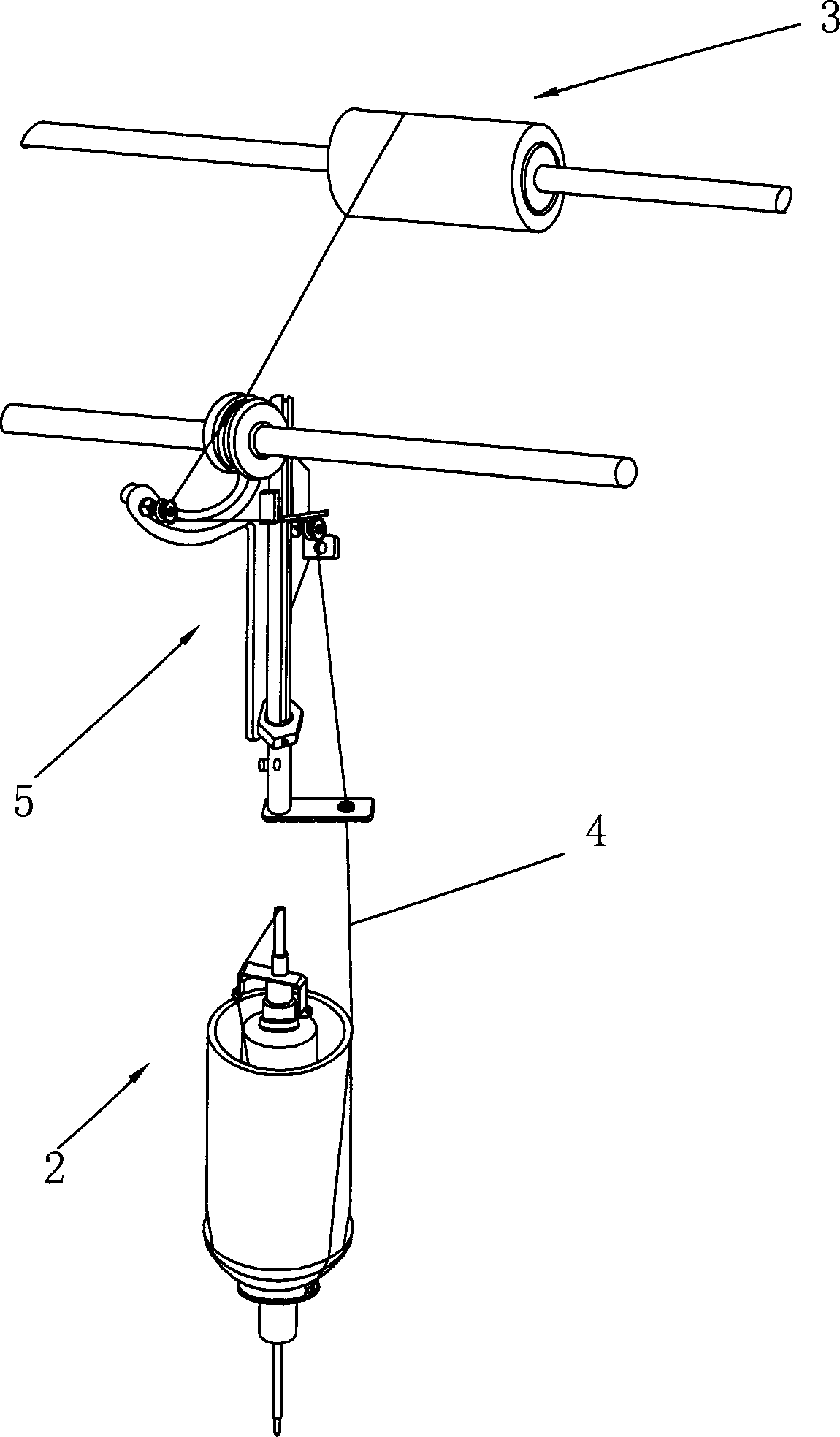

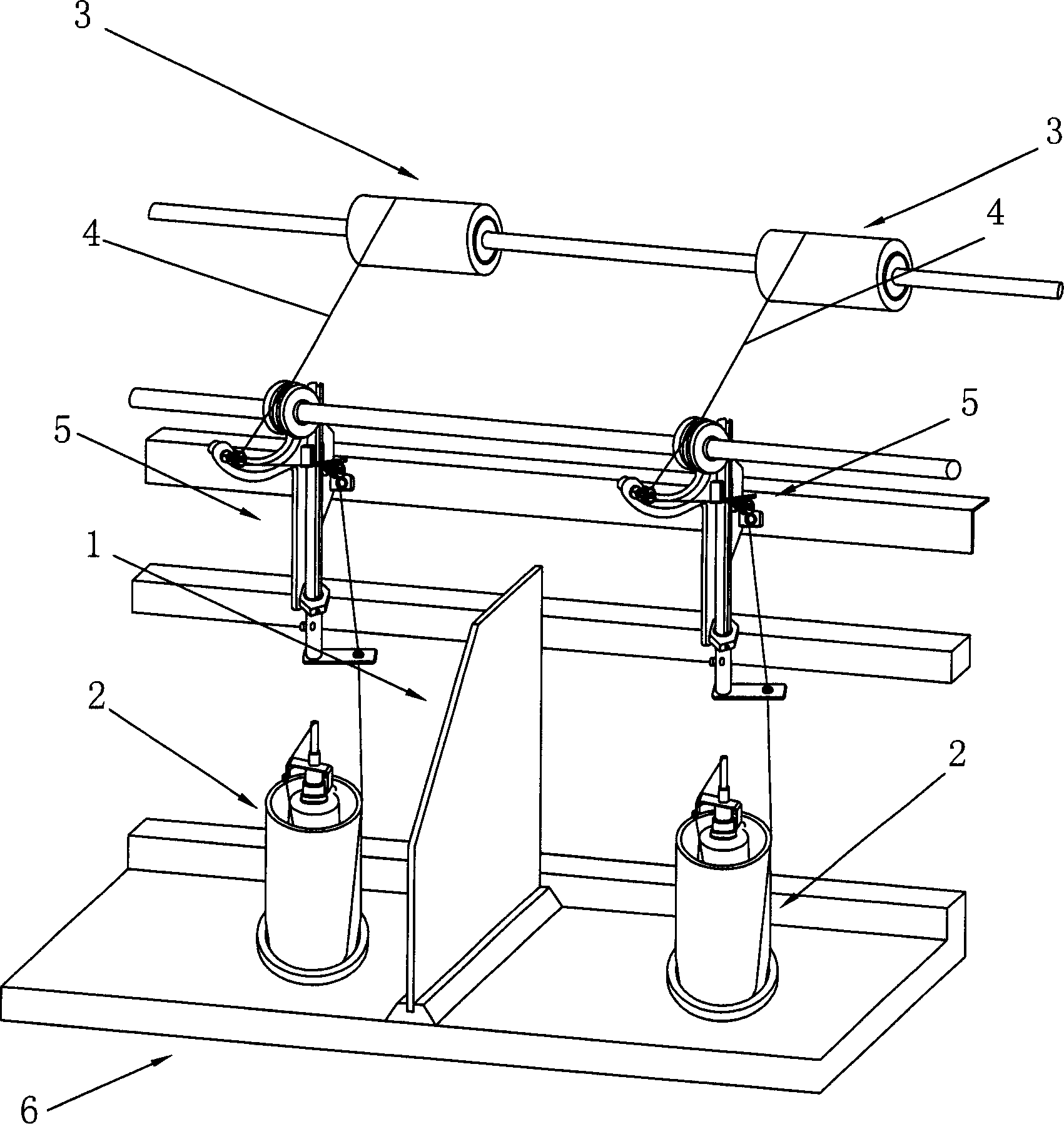

[0011] See attached figure 1 - attached image 3 As shown, a two-for-one twister includes a frame 6, at least two yarn storage drums 2 arranged on the frame 6, a yarn guide device 5 and a winding device arranged on the frame 6 3. The yarn guiding device 5 is located between the yarn storage drum 2 and the winding device 3, and the frame 6 between the two adjacent yarn storage drums 2 is provided with a yarn separator 1, and the said The screen separator 1 is a stainless steel plate with a smooth outer surface.

[0012] See attached figure 1 As shown, the yarn storage drum 2 makes the yarn 4 twisted, and the winding device 3 winds up two or more twisted yarns 4 .

[0013] When the yarn storage drum 2 is working, the yarn 4 will rotate at a high speed, and the yarn 4 that rotates at a high speed and moves upward will touch the yarn separator. Since the yarn separator 1 is a stainless steel plate with a smooth surface, it will 4 When touching, it can prevent the yarn 4 from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com