Safety belt automatic flexing device with free wheel clutch

A technology of automatic retractable device and seat belt, applied in the direction of seat belt, belt tensioner, transportation and packaging in the car, which can solve the problems of breaking the balance spring, excessive rotation, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

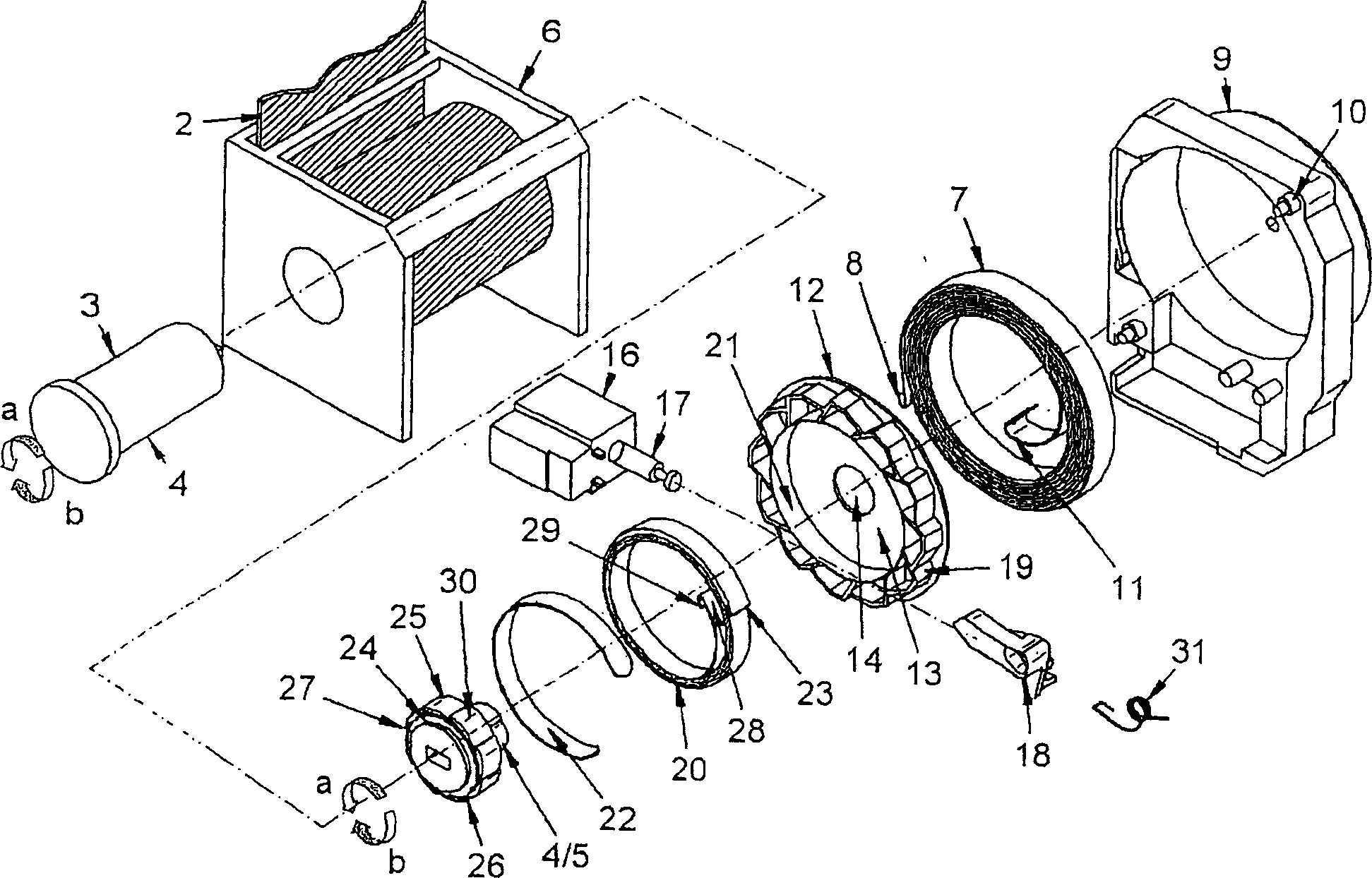

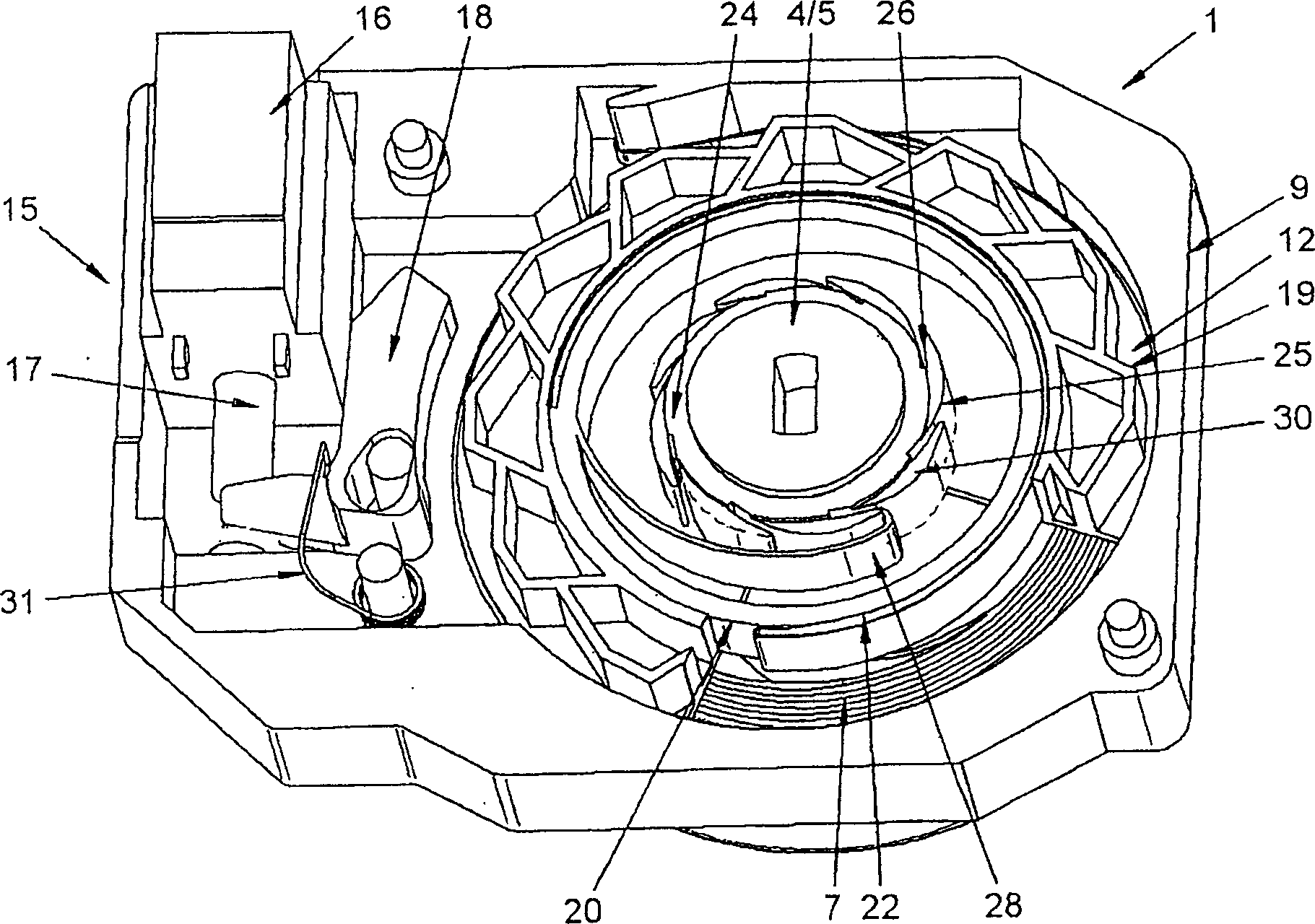

[0026] Shown among the figure is a safety belt automatic telescoping device 1. The belt retractor 1 can be used to wind the belt 2 onto the belt take-up section 3 of the shaft 4 . The shaft 4 consists of two parts and the parts comprise the belt take-up section 3 and the drive section 5 . The shaft 4 is rotatably housed in a metal casing 6 .

[0027] In addition, the seat belt automatic retractor 1 includes a main drive spring 7 which is fixedly connected to its outer end 8 with a plastic housing 9 . The plastic housing 9 is connected laterally to the metal housing 6 by means of three pins 10 .

[0028] The main drive spring 7 connects its inner end 11 in a rotationally fixed manner to the drive section 5 of the shaft 4 . The shaft 4 is thus pretensioned by the main drive spring 7 in the winding direction a when the shaft 4 is rotated in the unwinding direction b, ie when the seat belt 2 is unrolled.

[0029] Furthermore, the automatic seat belt retractor 1 also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com