Adjustable wedged spring leaf type buckle and its fastening method

A new type of shrapnel technology, applied in the directions of roads, tracks, buildings, etc., can solve the problems of inability to meet the on-site use requirements of railway turnouts, installation difficulties, insufficient strength of shrapnel and pins, and avoid the problem of shrapnel pins. Simple and flexible installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

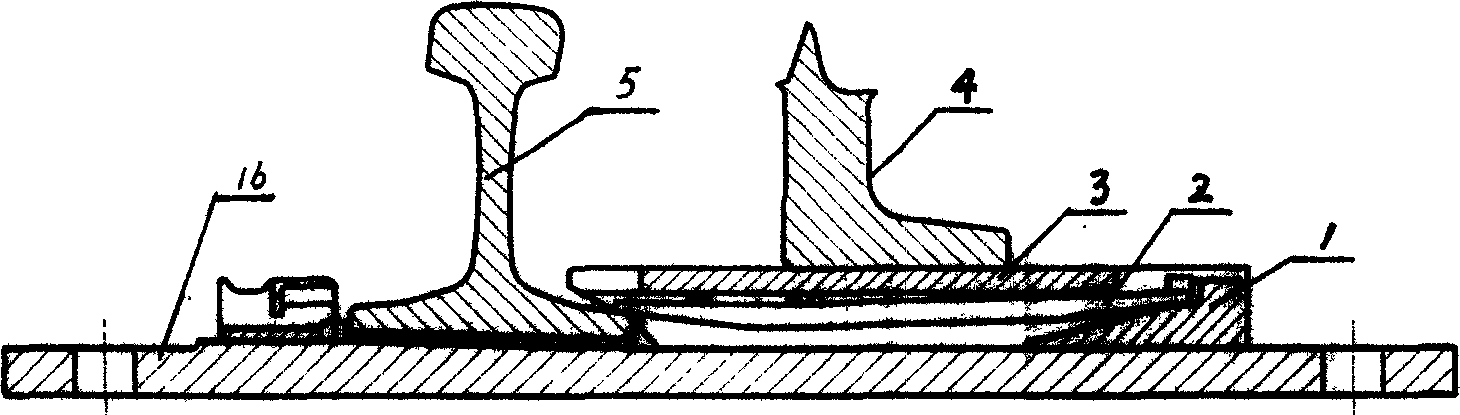

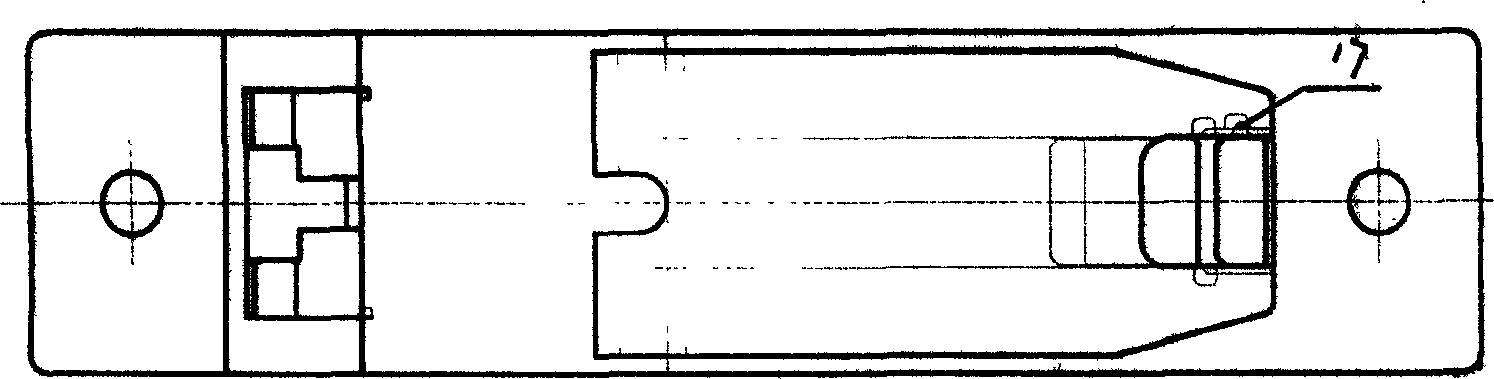

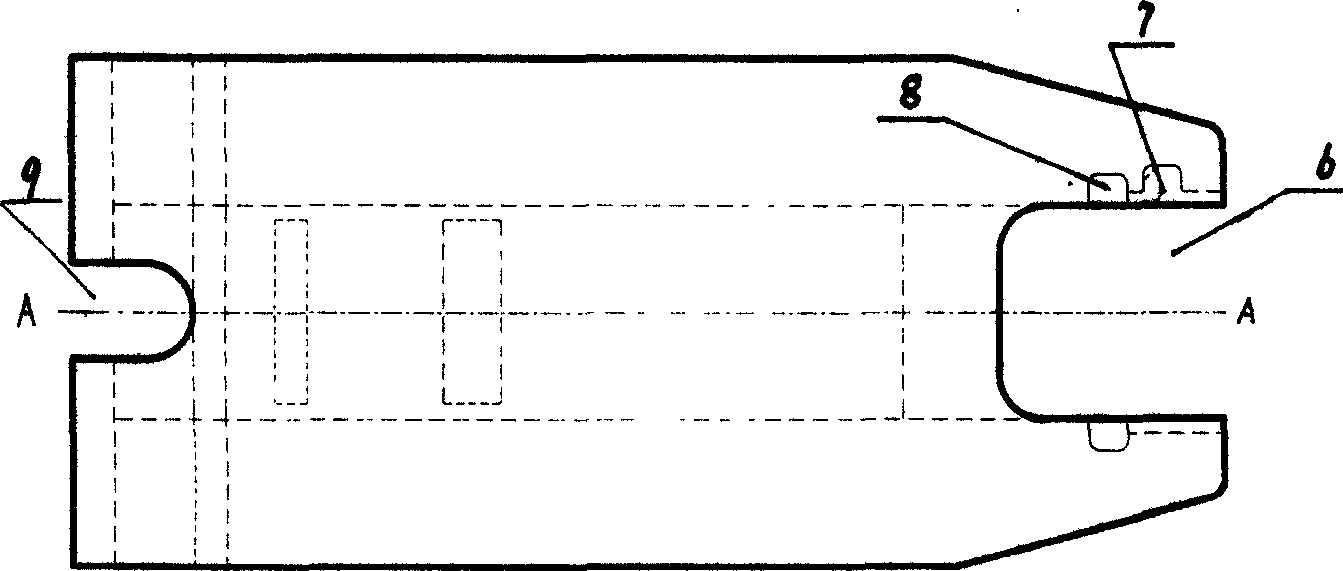

[0020] Embodiment 1: with reference to attached Figure 1-7 . The wedge-shaped adjustment is a new type of shrapnel type fastener, and the point rail 4 is located on the platen 3. The processing and manufacturing of the point rail 4 is a prior art, so it will not be described here. For shrapnel 2, refer to the attached Figure 5 and 6 Made by existing processing technology and positioned at the platen cavity 10, both sides of the rear end of the shrapnel 2 are provided with bosses 15 and match with the groove 8 on the wall of the large U-shaped opening 6 in the platen. The rear end of the elastic sheet 2 is located on the wedge-shaped surface 14 of the wedge-shaped positioning block 1 , that is to say, the wedge-shaped positioning block 1 is located at the rear end of the platen cavity 10 and the wedge-shaped surface 14 of the wedge-shaped positioning block is used to support the rear end of the elastic sheet 2 . The platen cavity 10 adopts prior art processing and forming,...

Embodiment 2

[0021] Embodiment 2: The buckling method of the wedge-shaped adjustment of the new type of spring-type fastener, the rail bottom on one side of the basic rail 5 is fixed on the bottom plate 16, the point rail 4 is located on the table 3, the spring 2 is located in the inner cavity 10 of the table, and the spring 2 is The front end is located on the rail bottom on the other side of the basic rail 5, the rear end of the elastic piece 2 is located on the wedge-shaped surface 14 of the wedge-shaped positioning block and is lifted by the wedge-shaped surface, and the middle part of the elastic piece 2 is pressed against the supporting boss 11 of the inner cavity of the platen. Hold, under the action of external force, the shrapnel 2 is forced to be upturned at both ends and concave in the middle. The wedge-shaped positioning block at the middle boss and the rear end forces the shrapnel 2 on the bottom of the rail on the other side of the basic rail to generate buckling pressure. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com