Gas-solid cyclone separator

A technology of gas-solid cyclone separation and cyclone separator, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc., to achieve the effect of simple structure, low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

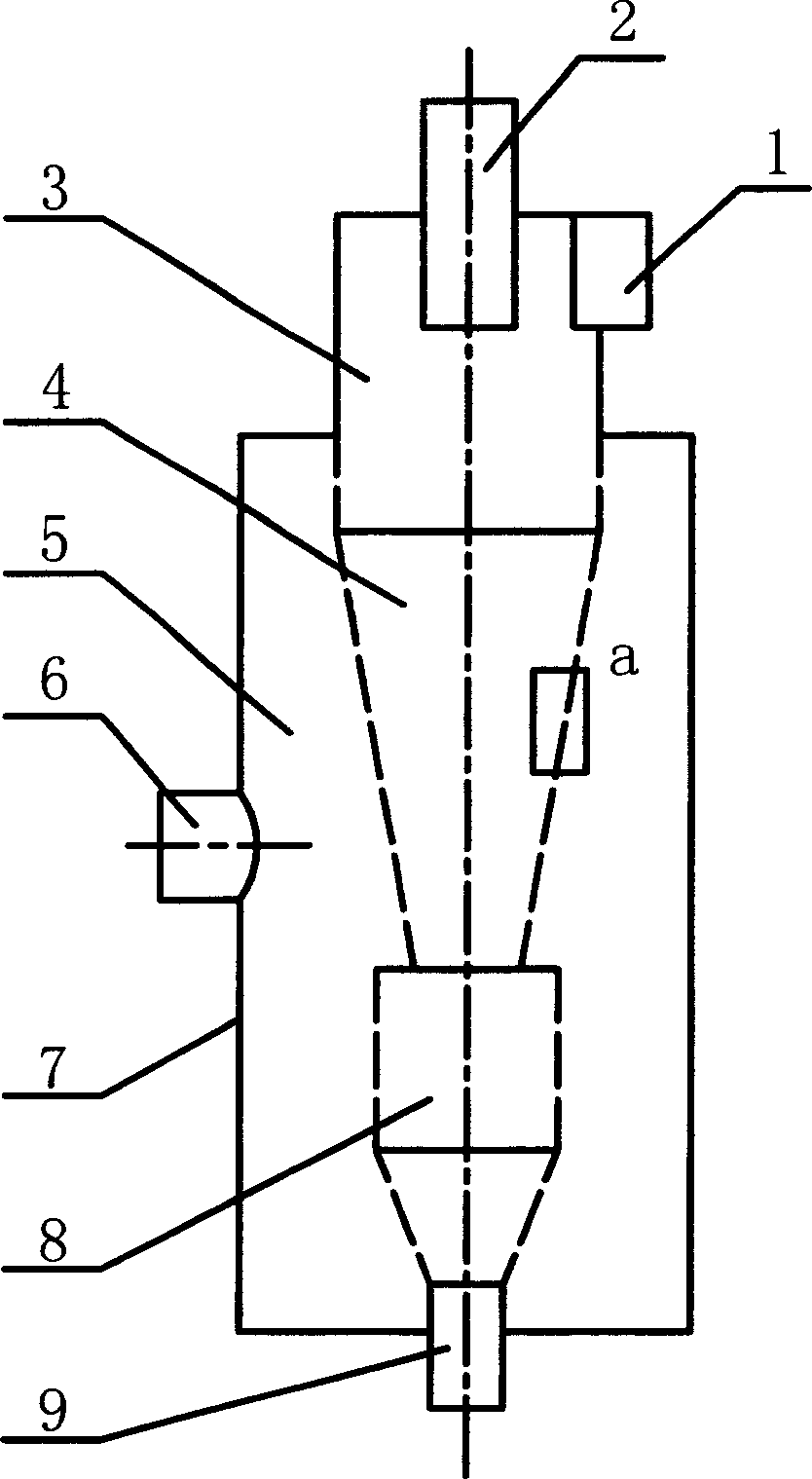

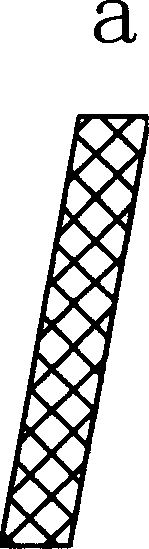

[0045] Figure 4 and Figure 5 A schematic structural diagram showing Embodiment 1 of the gas-solid cyclone separator of the present invention. In this embodiment, the lower end of the exhaust pipe is frusto-conical, and there is a feed inlet 1, which is a straight-cut inlet structure in which the feed inlet 1 and the cylinder body 3 are cut directly, and the cone 4 of the cyclone separator The wall of the ash hopper 8 is made of porous metal filter material. The outside of the cone 4 and the ash hopper 8 is surrounded and closed by the outer cylinder 7 to form a gas collection chamber 5. The outer cylinder 7 is in the same shape as the cone 4 and the ash hopper 8. The axis is arranged, and the middle part of the outer cylindrical body 7 has a filtered gas discharge port 6, which is used to discharge and / or draw out the filtered gas under negative pressure.

Embodiment 2

[0047] Figure 6 and Figure 7 A schematic structural diagram showing Embodiment 2 of the gas-solid cyclone separator of the present invention. In this embodiment, there are two feed inlets 1, which are double straight-cut inlet structures in which the two feed inlets are respectively cut directly with the cylinder body 3, and are used to increase the feed amount. The cone of the cyclone separator 4 and the walls of the ash hopper 8 are made of porous metal filter material, and the outside of the cone 4 and the ash hopper 8 is surrounded and closed by the outer cylinder 7 to form a gas collection chamber 5, and the outer cylinder 7 and the cone 4 and the ash hopper 8 form a The coaxial line is arranged, and the middle part of the outer cylinder body 7 has a filtered gas discharge port 6, which is used for discharging and / or extracting the filtered gas under negative pressure.

Embodiment 3

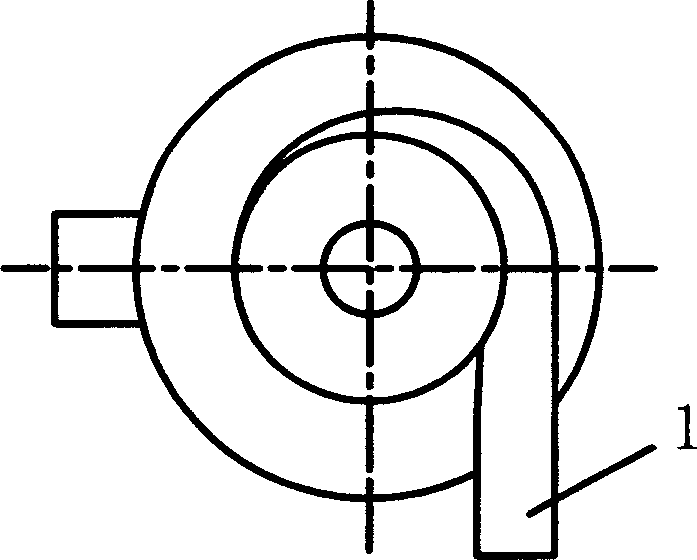

[0049] Figure 8 and Figure 9 A schematic structural diagram showing Embodiment 3 of the gas-solid cyclone separator of the present invention. In this embodiment, there is a feed port 1, which is a volute structure in which the feed port 1 is tangent to the cylinder body 3. Part of the cylinder body 3 of the cyclone separator is made of porous metal filter material, and part of the cylinder body 3 is surrounded and closed by the outer cylinder 7 to form the gas collection chamber 5, the outer cylinder 7 is arranged coaxially with the cylinder 3, and the middle part of the outer cylinder 7 has a filter gas discharge port 6 for discharging and / or negative air. The filtered gas is pumped out under pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com