Three-rod module attitude coutrol mechanism test method

A technology of attitude control and testing methods, applied in general control systems, control/adjustment systems, test/monitoring control systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1, in the pre-research of the active main reflector of the large radio telescope "FAST" in my country, the test of the "three-rod module attitude control mechanism" used to control the movement of the active reflector unit block.

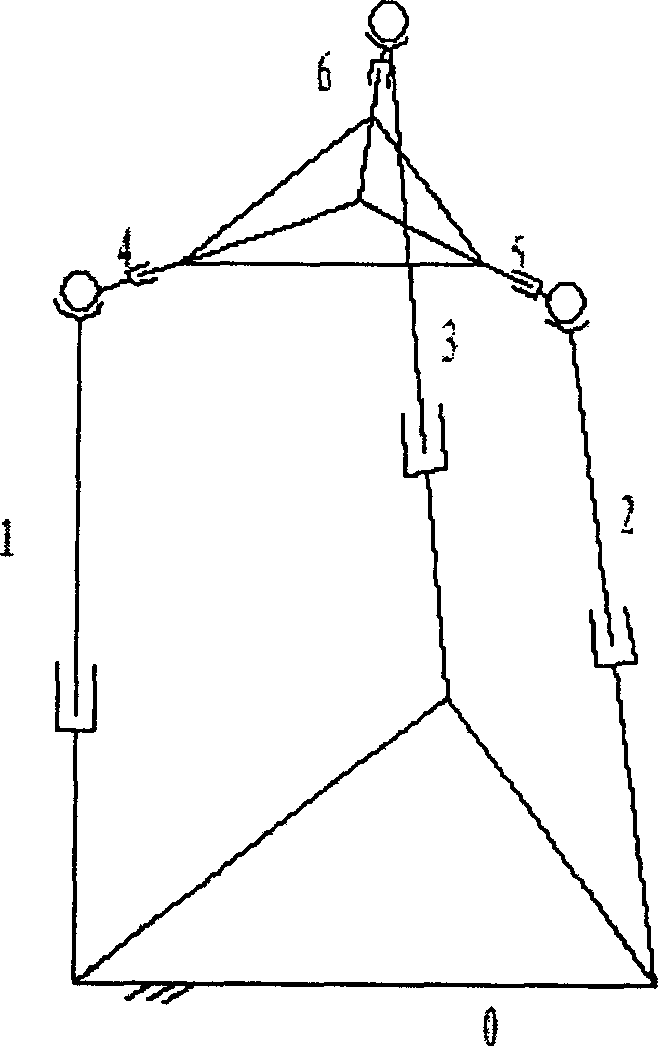

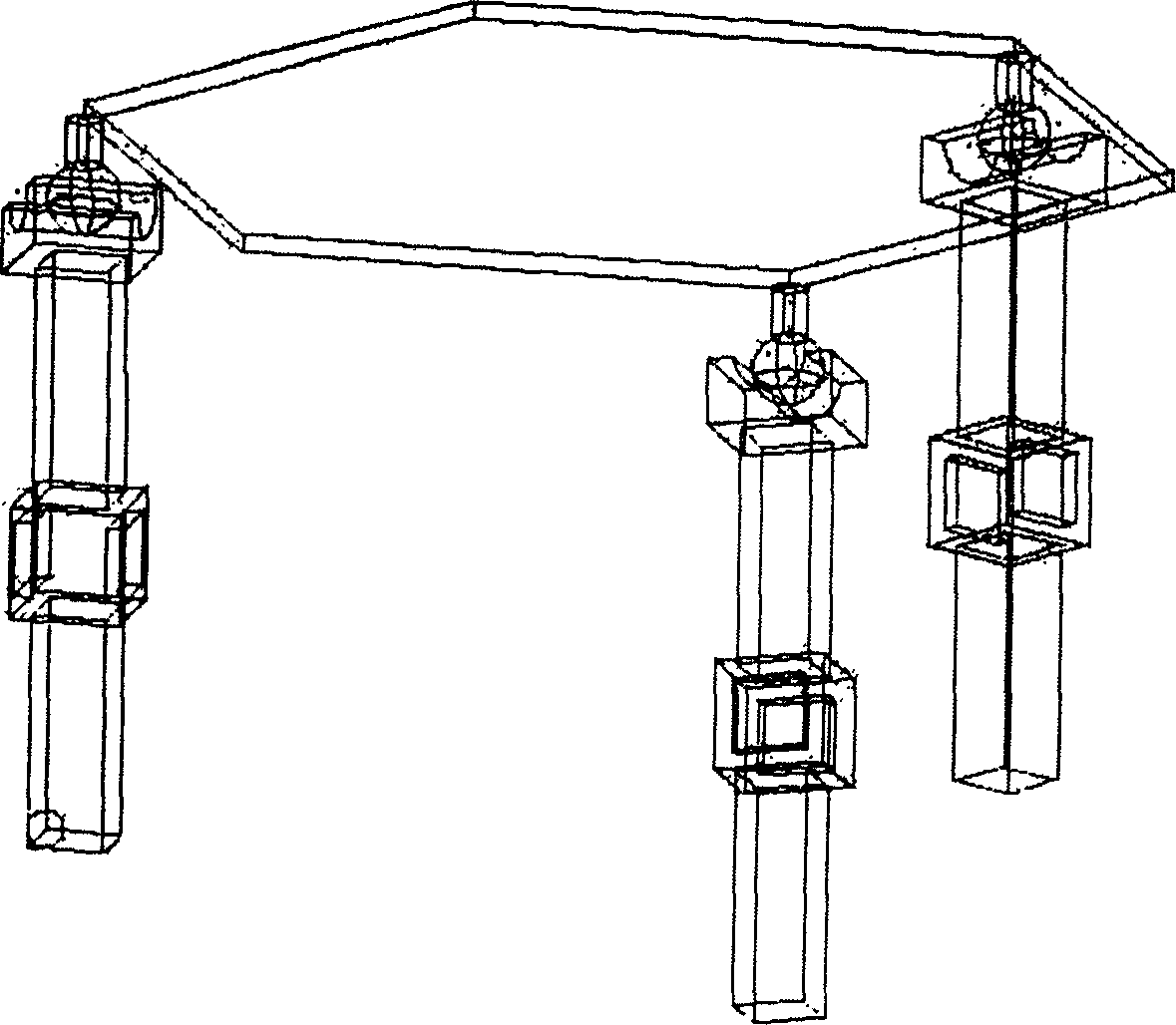

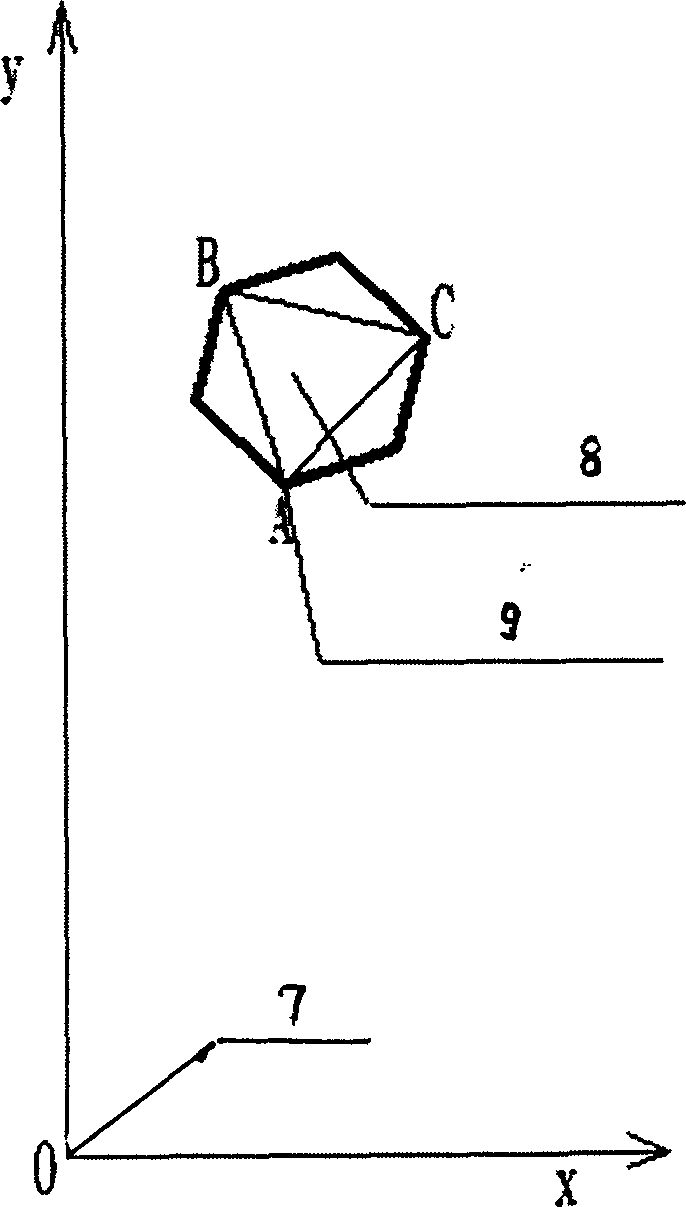

[0046] refer to figure 2 , image 3 : The installation and measurement of the experimental device of the three-bar module attitude control mechanism are completed with the help of a total station. First, the total station is placed on the fixed base at position 7 in the figure, and a target is pasted on a pillar about 42m away to establish a coordinate system. For the position of unit block 8 in the coordinate system see image 3 , 9 represents the measured point. Before each measurement, the target was re-measured with a total station to determine the initial position. Three main items are measured. The first is the positioning accuracy of the actuator; the second is the repositionability of the back frame and the actuator itse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com