Pulling device of sewing machine

A technology for sewing machines and objects to be sewn, applied to sewing machine components, sewing equipment, lubrication/cooling devices, etc., can solve problems such as heat generation and wear, and achieve low frictional resistance, reduced load, and stable high-speed operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

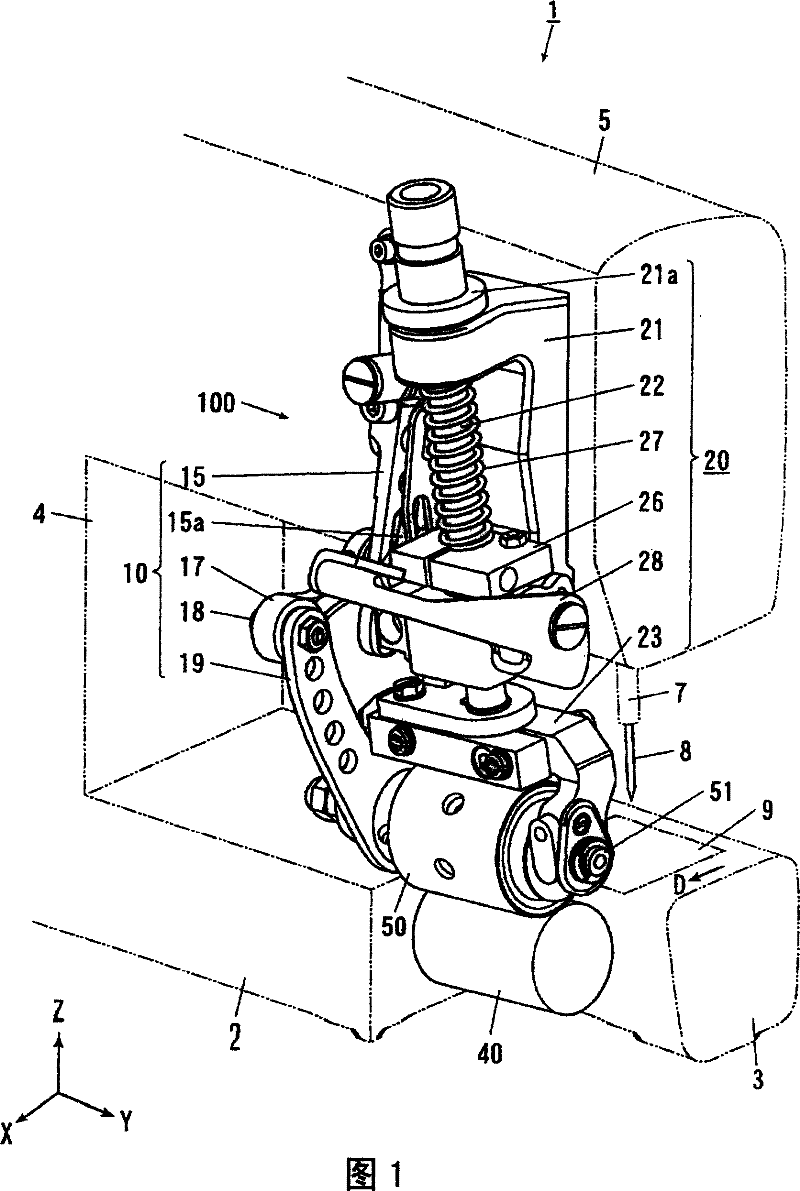

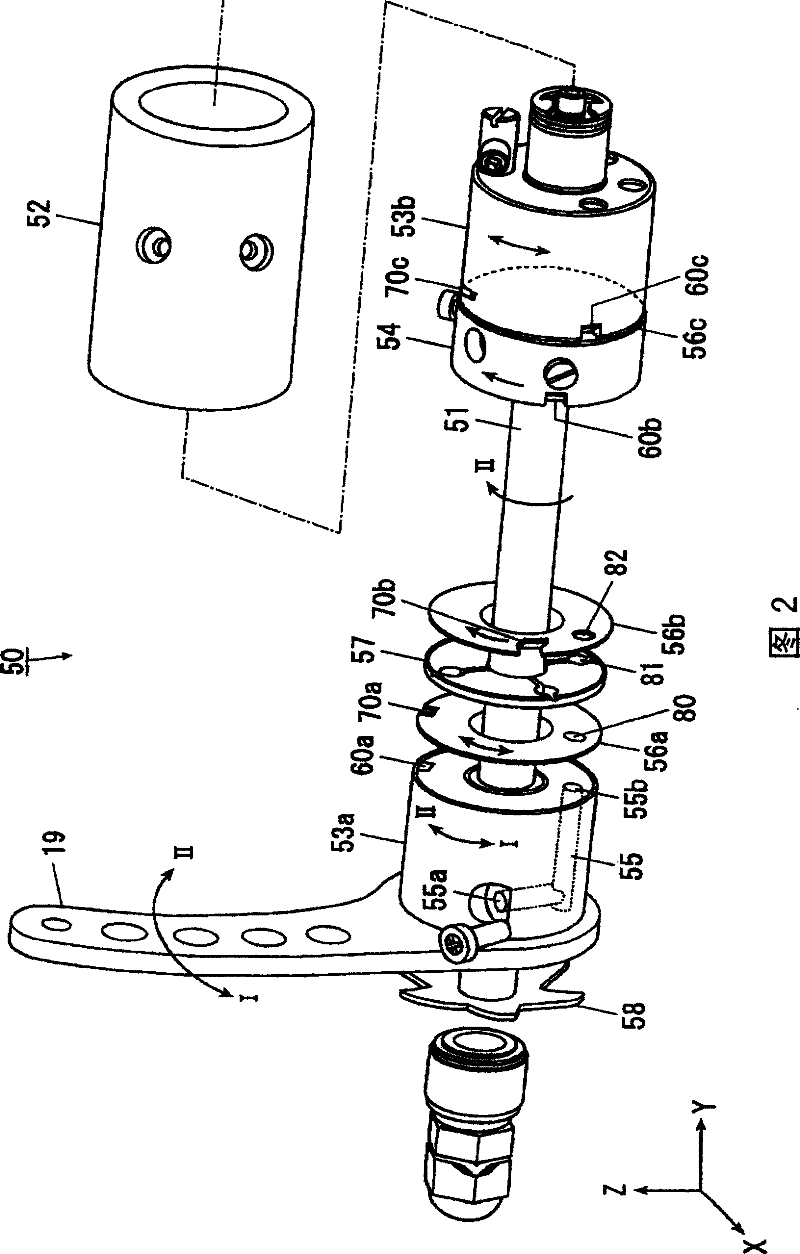

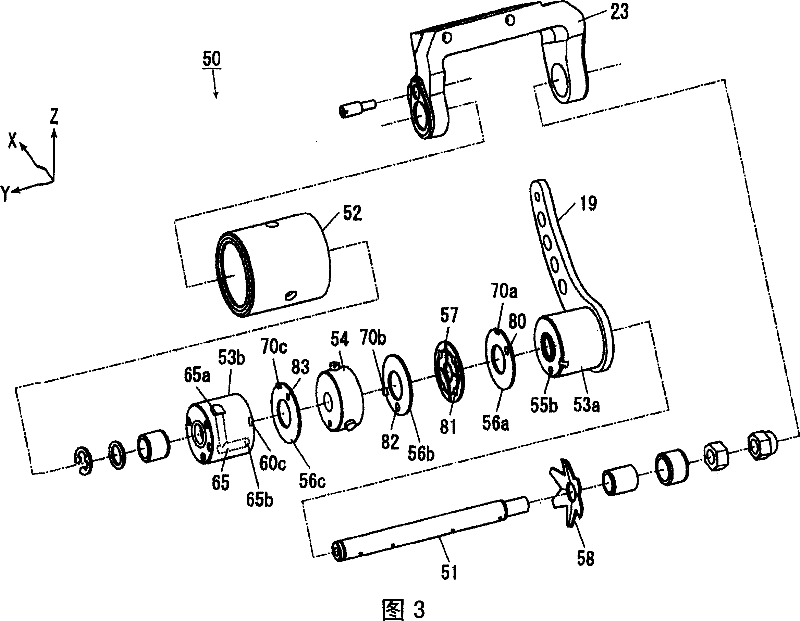

[0069] Below, based on Figure 1 to Figure 5 Embodiments of the present invention will be described in detail. In this embodiment, the pulling device 100 of the sewing machine is provided as the conveying mechanism, which applies a pulling force toward the downstream side in the conveying direction to the cloth on the downstream side of the sewing position in the conveying direction. Furthermore, in this embodiment, the direction in which the needle 8 moves up and down is referred to as the Z-axis direction (up-and-down direction), and one direction perpendicular thereto (the conveying direction of the object to be sewn) is referred to as the X-axis direction (front-rear direction). , the direction perpendicular to both the X-axis direction and the Z-axis direction will be described as the Y-axis direction (left-right direction). In addition, in this embodiment, the cloth which is a to-be-sewn object is conveyed in the X-axis direction, that is, figure 1 In the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com