Twisted netted piece single-wire strong testing method

A test method and mesh technology, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve problems such as inability to perform, and achieve reasonable and reliable technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

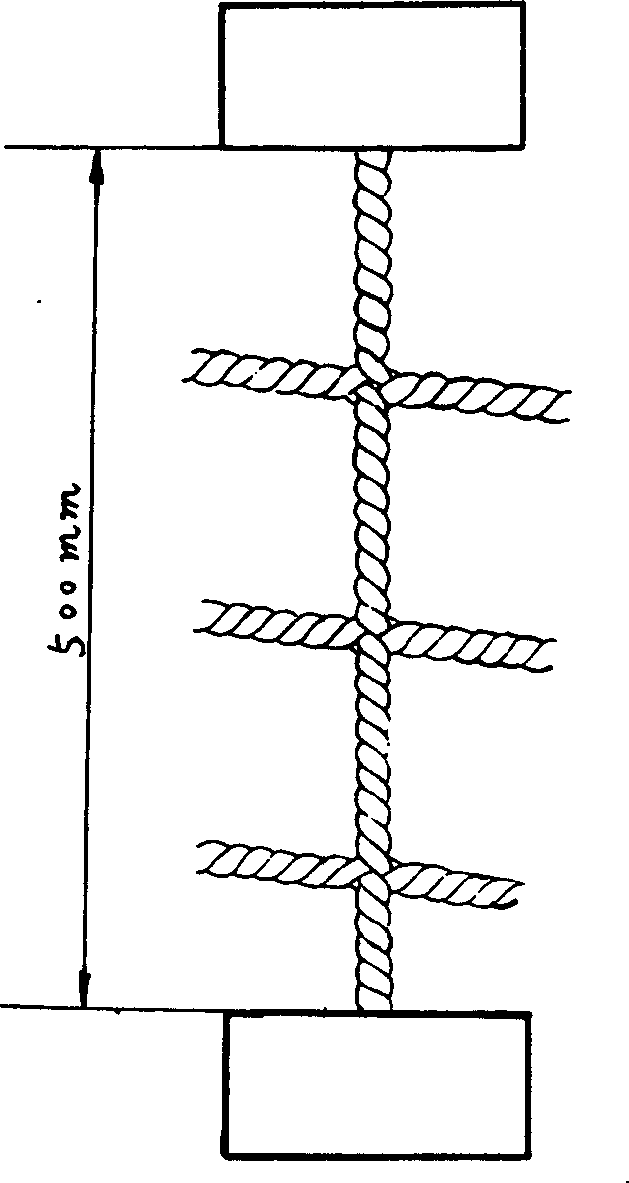

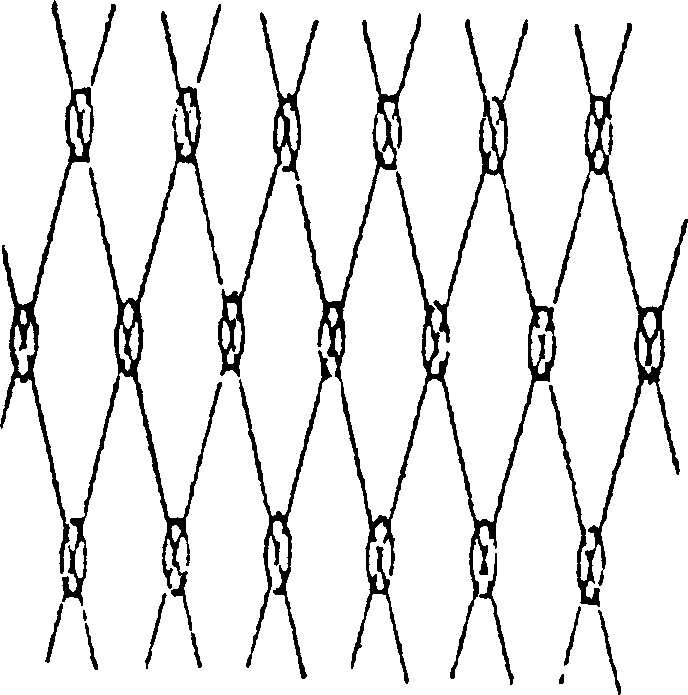

[0011] The sample is obtained from each part of the mesh at a distance of more than 5 meshes from the edge of the mesh; when the same project is tested, it is not continuously sampled in the same direction of the two mesh feet; all the mesh feet are cut along the oblique direction of the mesh to obtain The single network cable of the mesh foot is used as a sample for the single-wire strength test of the mesh, and the effective length of the sample between the fixtures is 500mm±1mm (see figure 1 ). The appearance inspection of the sample is carried out at normal temperature and humidity. During the test of the single-wire strength performance of the mesh, the laboratory temperature is (20±2)°C and the relative humidity is (65±5)%. The dry sample is balanced in the laboratory for more than 6 hours ; The wet sample is immersed in water with a water temperature of 20°C±2°C for more than 6 hours to reach a fully infiltrated state. After taking it out, hang it until the sample does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com